| Posted: Jun 05, 2013 | |

Flexible, carbon-based nanotechnology thin-film transistors |

|

| (Nanowerk Spotlight) Flexible electronics are all the rage these days. They promise an entirely new design tool like for instance, tiny smartphones that wrap around our wrists, and flexible displays that fold out as newspapers or large as a television; or photovoltaic cells and reconfigurable antennas that conform to the roofs and trunks of our cars; or flexible implants that can monitor and treat cancer or help paraplegics walk again (read more: "Flexible electronics could transform the way we make and use electronic devices"). | |

| Flexible electronics also might cost less to make. Conventional semiconductors require complex processes and multi-billion dollar foundries. Researchers hope to print flexible electronics on plastic film the same way we print ink on newspapers. Utilizing 3D printing, they could even be fully integrated into products. | |

| In terms of material selection, carbon nanotubes (CNTs) and graphene, along with hydrogen terminated amorphous-silicon, low-temperature polycrystalline silicon, semiconducting metal oxides and organic semiconductors, are promising candidates for flexible electronics. especially thin film transistors (TFTs) made of carbon-based materials such as graphene are expected to transform many technological applications. | |

| A recent article in Small ("A Review of Carbon Nanotube- and Graphene-Based Flexible Thin-Film Transistors") reviews the progress in single-walled CNT and graphene-based flexible thin-film transistors related to material preparation, fabrication technique and transistor performance control, in order to clarify the possible scale-up methods by which mature and realistic flexible electronics could be achieved. It highlights state-of-the-art all-carbon nanomaterial transistors and concludes that an all-carbon strategy is most promising to realize extremely flexible, stretchable and transparent electronics. | |

|

|

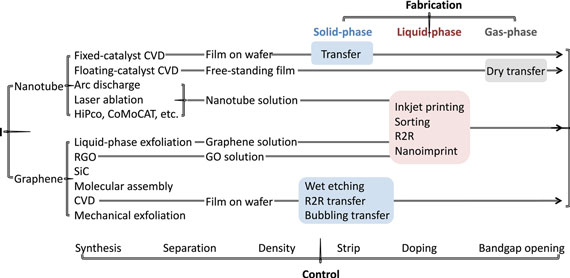

| From CNTs and graphene to flexible electronics. The schematic illustrates a few techniques in material synthesis and device fabrication which will possibly lead to flexible devices. Among them, only a few methodologies have the potential to be used for realistic flexible electronics. (Reprinted with permission from Wiley) (click image to enlarge) | |

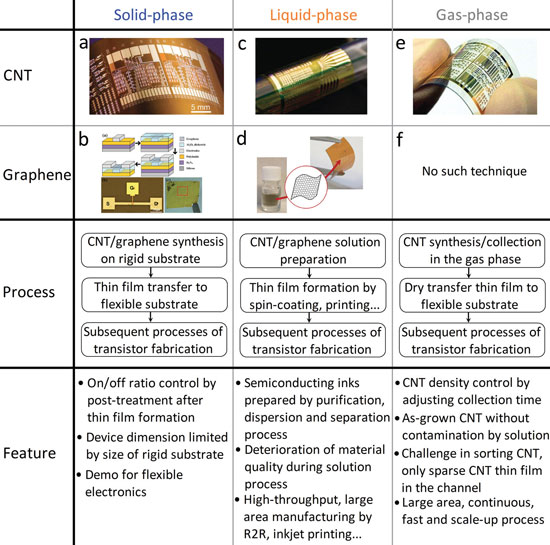

| The fabrication techniques for CNT- and graphene-based thin-film transistors can be divided into three categories – solid-phase, liquid-phase and gas-phase fabrications based on the different environments used for the production of CNT and graphene thin films. | |

| For solid-phase fabrication, CNTs or graphene supported on a solid and rigid wafer are detached from the wafer and transferred to a flexible substrate. For liquid-phase fabrication, CNTs or graphene dispersed in a solution is deposited on a flexible substrate by liquid-phase approaches including spin-coating, gravure/inkjet printing, nanoimprint, dielectrophoresis, etc. For gas-phase fabrication, a CNT thin film is formed in a gas-phase environment and directly dry-transferred to a substrate to make flexible devices. But at present, there are no such techniques reported for graphene. | |

|

|

| Fabrication techniques of CNT- and graphene-based flexible thin-film transistors. Here, the fabrication techniques are divided into three categories: solid-phase, liquid-phase and gas-phase, for CNTs and graphene. The representative examples, main processes of the fabrication techniques and their main features are listed. a) Medium-scale CNT thin-film integrated circuits, where a CNT thin film synthesized by CVD was transferred from a Si/SiO2 substrate to a polyimide substrate. b) High-mobility detachable embedded-gate graphene transistors, where the CVD-graphene was transferred from a Cu-coated substrate onto a polyimide-coated substrate. c) CNT digital, analog and radio-frequency integrated circuits, where a CNT solution containing 99% semiconducting CNTs separated by the DGU method was spin-coated onto a polyimide substrate. d) Flexible gigahertz graphene transistors, where a graphene-solution was deposited on a polyimide substrate by dielectrophoresis. e) CNT sequential logic circuit, where CNTs synthesized by a floating-catalyst CVD were directly transferred to a polyethylene naphthalate substrate. f) The empty cell indicates that no graphene gas-phase fabrication technique is available at present. (Reprinted with permission from Wiley) | |

| The key performance issues for thin-film transistors are large carrier mobilities and high on/off ratios for high-speed operation and low-energy consumption. The main challenge is a mixture of semiconducting and metallic CNTs in the conventional as-grown CNTs, while the absence of a bandgap is an obstacle for graphene. In their review, the authors address these issues in detail and describe current research efforts to improve performance of carbon-based TFTs. | |

| The final section of the review focuses on all-nanocarbon TFT devices: "Because CNTs and graphene thin films are excellent electrical conductors, they are promising for the practical production of transparent conductive films (TCFs) due to their unique electrical and optical properties. Compared to a transparent ITO TCF, a CNT- and graphene-based TCF has strong competitive advantages including a lower cost and better flexibility. Therefore, all-carbon thin-film transistors using CNT or graphene as electrodes are expected to enable the fabrication of high-performance, flexible, transparent and stretchable devices using relatively simple and low-cost techniques." | |

| Concluding their review, the authors stress that the most urgent task at present is to fabricate flexible, stretchable and transparent electronics by using a high-throughput, low-cost, and industrial scale-up technique, rather than conventional semiconductor manufacturing in the laboratory. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|