| Posted: Nov 01, 2007 | |

Bullets harmlessly bouncing off nanotechnology T-shirts |

|

| (Nanowerk Spotlight) Granted, they don't sell them at Gap yet, but if current research undertaken by scientists in Australia is any indication, bullet-proof vests as light as T-shirts could become reality in the not too-distant future. Carbon nanotubes (CNTs) have great potential applications in making ballistic-resistance materials. The remarkable properties of CNTs makes them an ideal candidate for reinforcing polymers and other materials, and could lead to applications such as ligh-weight bullet-proof vests or shields for military vehicles and spacecraft. For these applications, thinner, lighter, and more flexible materials with superior dynamic mechanical properties are required than what is currently available. Ongoing research at the University of Sydney explores the energy absorption capacity of single-walled carbon nanotubes under a ballistic impact. CNT reinforced materials might not only be very effective in stopping ballistic penetration or high speed impact, like Kevlar vests, but they might also be able to prevent the blunt force trauma that still is a problem with today's body armor. | |

| "When a bullet strikes body armor, the fibers of these materials absorb and disperse the impact energy to successive layers to prevent the bullet from penetrating" Dr. Liangchi Zhang explains to Nanowerk. "However, the dissipating forces can still cause non-penetrating injuries which is known as blunt force trauma. Even when the bullet is stopped by the fabric, the impact and the resulting trauma would leave a severe bruise and, at worst, damage critical organs. Hence the best material for body armor should have a high level of elastic storage energy that will cause the bullet to bounce off or be deflected." | |

| Zhang, a professor at the School of Aerospace, Mechanical and Mechatronic Engineering at the University of Sydney, has been working on the energy absorption capacity of carbon nanotubes under ballistic impact. | |

| In a Nanowerk Spotlight last year we reported on Zhang's research about the energy absorption capacity of different radii CNTs under ballistic impact (Carbon nanotubes could make t-shirts bullet proof). The somewhat unrealistic assumption in this initial research was that the bullet moves with constant speed. | |

| Zhang points out though, that the challenge in exploring the ballistic resistance capacity of carbon nanotubes lies in the understanding of the bullet impact mechanism involving how the force, energy, momentum and velocity vary in the time domain at ballistic striking. In new findings, reported in a recent paper in the October 17, 2007 online edition of Nanotechnology, he aims to resolve this problem ("Ballistic resistance capacity of carbon nanotubes"). | |

|

|

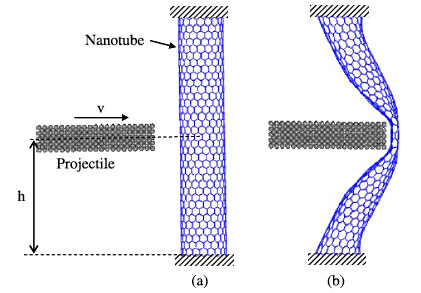

| The molecular dynamics model of a carbon nanotube subjected to ballistic impact. (a) Initial model, (b) a deformed nanotube at its maximum energy absorption. (Reprinted with permission from IOP Publishing) | |

| "In our latest study we looked at a more 'real' ballistic impingement process" says Zhang: "The speed of a bullet reduces due to its energy loss when impacting a CNT (the energy is absorbed by the CNT), becomes zero when its forward motion is fully stopped by the CNT, and is bounced back when the CNT releases its energy stored. This gives a more complete picture of the whole process." | |

| Furthermore, Zhang and his team extended the nanoscopic simulation result to a macroscopic estimation to try to get a very rough feeling about the possibility of making a better bullet-resistant material based on a fabric of CNT-fibers, although this extension involves strong assumptions. For example, the scientists assume that in the macroscopic scale, the CNT will have the same end-clamping conditions and its lattice structure is perfect throughout. | |

| For their simulations, the scientists released a 'bullet' (made of nanoscale diamond with the dimensions 35.6 x 36.6 x 7.1 cubic Å) at a speed varying from 1,000 to 3,500 meters per second. In comparison, the initial velocity of modern rifle bullets is somewhere between 180 and 1500 m/s, depending on gun and bullet type. For a typical over-the-counter gun the speed is below 1000 m/s. | |

| Based on the properties of CNTs that they obtained in their simulations, the scientists carried out a case study as a potential application example. | |

| "We may very roughly estimate the thickness of a possible CNT body armor material composed of several layers of woven carbon nanotube yarns if we can assume that the nanoscale properties can be extended simply to a macroscale case" says Zhang. "We feel this is justified because, when a CNT is grown, its diameter is in nanometers but its atomic structure along its length, in micrometers, does not change. In other words, it is completely different to the metal case of the microstructural change from monocrystalline to polycrystalline." | |

| Taking their assumptions, the researchers estimate that a 600 micrometer thick body armor woven from six layers of CNT yarn – the same thickness as a very fine T-shirt – is sufficient to bounce off a .358 inch revolver bullet with a muzzle energy of 320 Joules. | |

| Zhang also found that nanotubes have an excellent resistance to repeated ballistic impacts, which is essential for body armor. | |

| Compared with Zhang's previous study from last year, this is a step towards the application of the dynamics properties of CNTs. Zhang points out, though, that there is much work ahead, though, e.g., uncertainties in terms of the scale effect and the availability of sensitive techniques for making such fabric materials. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|