| Posted: Aug 26, 2013 | |

Solar paint paves the way for low-cost photovoltaics |

|

| (Nanowerk Spotlight) Using quantum dots as the basis for solar cells is not a new idea, but attempts to make such devices have not yet achieved sufficiently high efficiency in converting sunlight to power. The latest advances in quantum dots photovoltaics have recently resulted in solar cell power conversion efficiencies exceeding 7% (see for instance: "Graded Doping for Enhanced Colloidal Quantum Dot Photovoltaics"). Although these performance levels are promising, all high-performing device results to date have relied on a multiple-layer-by-layer strategy for film fabrication rather than employing a single-layer deposition process. | |

| The attractiveness of using quantum dots for making solar cells lies in several advantages over other approaches: They can be manufactured in an energy-saving room-temperature process; they can be made from abundant, inexpensive materials that do not require extensive purification, as silicon does; and they can be applied to a variety of inexpensive and even flexible substrate materials, such as lightweight plastics. | |

| In new work, reported in the August 12, 2013 online edition of Advanced Materials ("Directly Deposited Quantum Dot Solids Using a Colloidally Stable Nanoparticle Ink"), a research team from the University of Toronto and King Abdullah University of Science and Technology (KAUST) developed a semiconductor ink with the goal of enabling the coating of large areas of solar cell substrates in a single deposition step and thereby eliminating tens of deposition steps necessary with the previous layer-by-layer method. | |

| "We sought an approach that would achieve highly efficient utilization of CQD materials," says Professor Ted Sargent from the University of Toronto, who, together with Osman Bakr, an assistant professor in the Solar & Photovoltaics Engineering Research Center at KAUST, led the work. "To achieve this, we made a solar cell ink that can be deposited in a single step which makes it an excellent material for high-throughput commercial fabrication." | |

| The team's 'solar paint' is composed of semiconductor nanoparticles synthesized in solution – so-called colloidal quantum dots (CQDs). They can be used to harvest electricity from the entire solar spectrum because their energy levels can be tuned by simply changing the size of the particle. | |

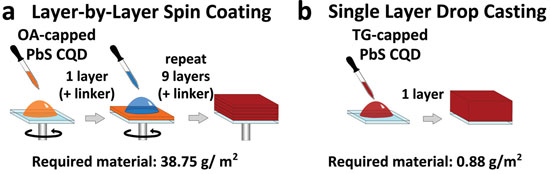

| Previously, films made from these nanoparticles were built up in a layer-by-layer fashion where each of the thin CQD film deposition steps is followed by curing and washing steps to densify the film and form the final semiconducting material. These additional steps are required to exchange the long ligands that keep the CQDs stable in solution for short ligands that allow efficient charge transport. However, this means that many steps are required to build a thick enough film to absorb enough sunlight. | |

| "We simplified this process by engineering the CQD surfaces with short organic molecules in the solution phase to enable a stable colloidal solution and reduce the film formation to a single step," Bakr explains to Nanowerk. "At the same time, the post processing steps are reduced significantly, since the semiconducting material is formed in solution. This means that CQD films can be deposited quickly and at low cost, similar to a paint or ink." | |

|

|

| a) Schematic of the standard layer-by-layer spin-coating process with active materials usage yield and required total material indicated. b) Schematic of the single-step film process with active materials usage yield and required total material indicated. (Reprinted with permission from Wiley-VCH Verlag) | |

| Besides the reduction in processing steps, the new process is also much more efficient in terms of materials usage. While the layer-by-layer, solid-state treatment approach provides less than 0.1% yield in its application of CQD materials from their solution phase onto the substrate, the new approach achieves almost 100% use of available CQDs. | |

| "This means that for the same amount of CQD material, we could make a thousand-fold larger area of solar cells compared with conventional methods," Bakr points out. "Our technology paves the way for low-cost photovoltaics that can be fabricated on flexible substrates using roll-to-roll manufacturing, similar to a printing press," adds Lisa Rollny, a PhD candidate in Sarget's group and a co-author of the paper. "Our ink is also useful in biological applications, e.g. in biosensors and tracing agents with an infrared response." | |

| "In previous work, we found new routes of passivating the CQD surface using a combination of organic and inorganic compounds in a solid state approach with large improvements in efficiency," says Rollny. "We intend to integrate this knowledge with our solar CQD ink to further improve the performance of this material, especially in terms of how much solar energy is converted into usable electrical energy." | |

| Although the team have developed an effective method for producing a CQD film in a single step, the electronic properties of the resulting films are not optimized yet. This is due to the very small imperfections on the CQD surface that reduce the usable electricity output of a solar cell. Through careful engineering of CQD surfaces in solution, the researchers plan to eliminate these unwanted surface sites in order to make higher quality, higher efficiency CQD solar cells using their single step process. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|