| Posted: Nov 08, 2013 | |

Wearable textile battery can be recharged by sunlight |

|

| (Nanowerk Spotlight) Going hand in hand with the development of wearable electronic textiles, researchers are also pushing the development of wearable and flexible energy storage to power those e-textiles. For instance, as we reported in a previous Nanowerk Spotlight ("Nanotechnology T-Shirt to replace batteries? Towards wearable energy storage"), scientists demonstrated that flexible cotton threads can be used as a platform to fabricate a cable-type supercapacitor. In another recent Spotlight we described the concept of foldable Li-ion batteries. | |

| Going one step further, a research team in Korea has now developed wearable textile batteries that can be integrated with flexible solar cells and thus be recharged by solar energy. | |

| Reporting their work in the October 28, 2013 online edition of Nano Letters ("Wearable Textile Battery Rechargeable by Solar Energy"), the team demonstrates a fully functional wearable textile battery by finding unconventional materials for all of the key battery components and integrating them systemically: Nickel-coated polyester yarn as a current collector for efficient stress release, polyurethane binder for strong adhesion of active materials, and polyurethane separator with superior mechanical, electrochemical, and thermal properties. | |

|

|

| Wearable textile battery. (a) A photograph of wearable textile battery embedded in clothes together with its enlarged view of the inner cell structure. (b) Photograph and schematic representation of a watch with a wearable textile battery strap. (Left) 6 LEDs (1 yellow, 1 blue, and 4 whites were lighted up as a demonstration of a functioning watchstrap battery. (c) A schematic illustration of the cell configuration of the wearable textile battery. The key components are based on the materials suitable for flexibility and bendability. (Image: Dr. Jang Wook Choi, KAIST) | |

| "In developing wearable rechargeable batteries, the component requiring the most significant alteration from the conventional cell configuration is the current collector because the current collector largely dictates the mechanical properties of the entire cell," Jang Wook Choi, an Associate Professor at the Korea Advanced Institute of Science and Technology (KAIST), who led the work, explains to Nanowerk. "Along this direction, one of the most natural approaches would be to use textiles as current collectors after integration with conductive materials." | |

| Choi points out that the use of carbon nanomaterials for the fabrication of textile supercapacitors and paper batteries, as previously reported, has encountered limitations in increasing the cell size and rate performance. Also, the investigation of metal-incorporating current collectors, like silver-coated textiles, runs into cost issues as well as mechanical challenges with regard to fatigue failure. | |

| "In contrast, our battery cells endure extremely severe mechanical tests while delivering comparable electrochemical properties to those of the conventional foil-based counterparts," says Choi. "It is important that, for the wearable capability of the rechargeable battery, the binder and separator also support the mechanical endurance of the overall system." | |

| To this end, the researchers decided to investigate unconventional materials rather than modify existing one – which have been developed for conventional flat cells that do not need to withstand the demands of wearables. After searching a wide range of material candidates, they found that polyurethane – due to its chemical and polymeric structure – possesses various material properties that are suitable for both binder and separator in a wearable battery. | |

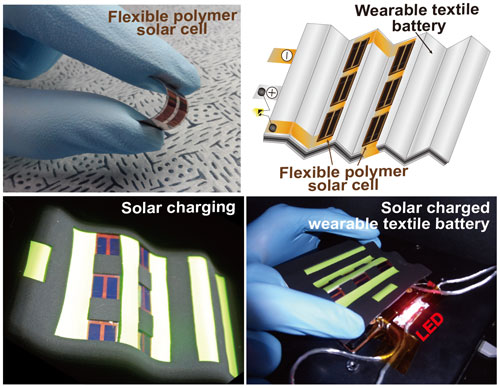

| Furthermore, flexible and lightweight solar cells based on plastic substrates were integrated onto the outer surface of the textile battery for recharging the textile battery without physical connection to power outlet. | |

| While changing or recharging the batteries in your watch or cell phone is a relatively simple operation, doing this with wearable batteries integrated into textiles might not be such an easy task. The team has therefore integrated a series of flexible polymer solar cells with its wearable textile battery. | |

|

|

| Integration with flexible polymer solar cells. (Image: Dr. Jang Wook Choi, KAIST) | |

| Choi notes that the wearable textile battery exhibited decent cycling and rate performance. "First, without folding-unfolding motions, our battery showed comparable performance to that of the foil-based counterpart. More importantly, the wearable textile battery showed good cycling performance even during severe folding-unfolding repetitions. After 40 cycles equivalent to 5500 deep folding-unfolding cycles, the textile battery retained 91.8% of the original capacity." | |

| The team attributes the relatively lower capacities during the folding-unfolding motions to the fact that such mechanical motions make ionic transport less efficient at various points of lithium diffusion including through the separator, at the electrode-electrolyte interface, and within the electrode films. | |

| "Our investigation demonstrates that materials and fabrication processes can be systemically united to realize a wearable textile battery with exceptional mechanical stability particularly in the forms of clothes and watchstraps," Choi sums up this work. "It is also reasonable to expect that further tuning of the cell dimensions will find various future applications beyond what can be conceptualized now, especially with the aid of solar-charging capabilities." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|