| Posted: Apr 30, 2014 | |

Wearable graphene strain sensors monitor human vital signs |

|

| (Nanowerk Spotlight) Monolayer graphene exhibits exceptional electronic and mechanical properties, making it, among other applications, a very promising material for nanoelectromechanical devices. Last year, for instance, researchers demonstrated that the piezoresistive effect in graphene in a nanoelectromechanical membrane configuration can provide direct electrical readout of pressure to strain transduction. | |

| Graphene's piezoresistive effect, combined with its other properties such as ultra-translucency, superior mechanical flexibility and stability, high restorability, and carrier mobility, enables the use of graphene in high-sensitivity strain sensors. | |

| Potential application areas for these sensors could be found in flexible display technology, robotics, smart clothing, electronic skin, in vitro diagnostics, implantable devices, and human physiological motion detection – which has been considered as an effective approach to evaluate human health. | |

| To demonstrate this application, researchers at Tsinghua University and Nanchang University in China have now reported on a method to monitor human motions. Their paper appeared in the April 14, 2014 online edition of Advanced Function Materials ("Wearable and Highly Sensitive Graphene Strain Sensors for Human Motion Monitoring"). | |

| "We prepared a simple-structured and low-cost graphene woven fabrics (GWFs) strain sensor, which can readily distinguish various strain levels of human motion signals," Hongwei Zhu, a professor at Tsinghua University, tells Nanowerk. "As we applied stress on the strain sensor, high-density cracks generated in the network, leading to the decrease of current pathways and the increase of resistance." | |

|

|

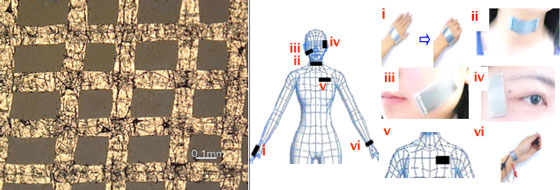

| Left: Optical photograph of a GWFs-PDMS-tape composite film. Right: Photo images of GWFs-PDMS-tape at various positions. (Image: Prof. Zhu, Tsinghua University) | |

| The team obtained their GWFs by using chemical vapor deposition (CVD) to grow graphene on the surface of crisscross copper meshes – similar with graphene growth on copper foil substrate. Subsequently, the copper mesh was etched away and the remaining graphene fabric transferred to a pretreated film composited with medical tape and PDMS glue, which is a flexible, biocompatible, shape controllable material. Completing the strain sensor was the connection of silver wires to the graphene mesh. | |

| When used as a human motion sensor, the signals of GWFs resistance change depend on deformation strain, which is formed by the motions. The stronger the motion is, the larger the strain is, and the easier the motion signals can be recorded. | |

| "Our GWF strain sensor can readily distinguish various strain levels of human motion signals," says Zhu. "Thanks to its special crisscross configuration compared to conventional graphene films, GWFs possesses an extremely high gauge factor, which we calculated to be ∼103 under 2-6% strains, 106 under higher strains (>7%), and ∼35 under small strain of 0.2%. This indicates that the sensor could be stretched by a tiny deformation of 0.2% with obvious resistance change, enough to be recorded." | |

| In other words, as Zhu notes, the signals of any weak motions, including vital signs such as pulse and breathing, phonation, expression changes, or blink of an eye, can be detected (as illustrated in the figure above). The sensor could also endure a large deformation of 30% with a completely reversible electrical property. | |

| "Owing to its distinctive features of high sensitivity and reversible extensibility, our graphene-based piezoresistive sensors have wide potential applications in the fields of flexible displays, robotics, fatigue detection, body monitoring, in vitro diagnostics, and advanced therapies," Zhu concludes. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|