| Posted: Dec 07, 2007 | |

The modest pipette becomes a nanotechnology surgery tool |

|

| (Nanowerk Spotlight) Pipettes (from the French: little pipe) are one of those ubiquitous tools you find in every chemical, medical or biology lab. The original pipette is made of glass and it works by creating a vacuum above the liquid-holding chamber and selectively releasing this vacuum to draw up and dispense liquid. With the advance of molecular biology, researchers required pipettes that were able to confine smaller and smaller amounts of specimen, not only for probing but also for injecting drugs, DNA etc. into cells - without damaging the cells, of course. Just a few months ago, researchers at the Brookhaven National Laboratory have developed what is thought to be the world's smallest pipette: made of a carbon-coated germanium nanowire it can hold a volume of only a few zeptoliters (a billionth of a trillionth of a liter, or one thousand cubic nanometers). Although today it even is possible to process the tip of a glass pipette to have an inner diameter as small as several tens of nanometers, this involves considerable problems in terms of the processing accuracy and the operability of the pipette, particularly in terms of locating the tip. It is generally considered that probes made from carbon nanotubes (CNTs) and nanoscale carbon pipes offer an attractive alternative to glass pipettes because of their small size, high mechanical strength, and high electrical conductivity. Researchers at the University of Pennsylvania have developed a manufacturing technique for carbon nanopipettes (CNPs) that does not require cumbersome nanoassembly and is amenable to mass production. | |

| "We are ultimately interested in developing nanosurgery tools to probe cells, monitor their processes, and control/alter their functions" Dr. Haim H. Bau tells Nanowerk. "At our Micro-Nano Fluidics Laboratory at the University of Pennsylvania, carbon nanopipettes are mass-produced and can inject reagents into cells without damage. We feel CNPs will help scientists gain a better understanding of how a cell functions and to help develop new drugs and therapeutics." | |

| Bau is a Professor of Mechanical Engineering and Applied Mechanics at the University of Pennsylvania in Philadelphia. He is currently conducting research on micro and nanofluidic phenomena with applications in biology and medicine. | |

| "We have developed a fabrication process, amenable for mass production, to produce CNPs without any assembly" Michael G. Schrlau explains to Nanowerk. "Our CNPs consist of a carbon film deposited inside quartz micropipettes to form a continuous, hollow, conductive carbon channel along its length. A unique property of CNPs is the existence of an electrically-conductive, hollow, interior carbon film running the entire length of the quartz pipette, lending itself to performing cell physiology measurements during cell injection." | |

| Schrlau, a PhD Candidate in Penn's Micro-Nano Fluidics Laboratory, is first author of a paper that was published in the November 29, 2007 online edition of Nanotechnology ("Carbon nanopipettes for cell probes and intracellular injection"). The work was carried out in collaboration with Professor Barry L. Ziober and Erica Falls from Penn's School of Medicine. | |

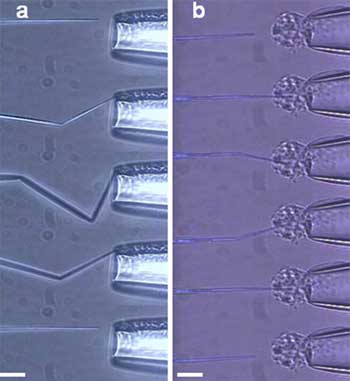

| The researchers found that their CNP tips are flexible and elastic, yet strong enough to readily spear cells. "Unlike glass pipettes which would shatter, we observed how CNPs buckle without breaking when pushed against a solid surface, then recover their original shape when the force is removed" says Schrlau. "Yet, the CNP is rigid enough to penetrate into smooth muscle cells. CNPs have successfully penetrated various cells such as oral squamous carcinoma cells and neuron cells. | |

|

|

| (a) From top to bottom: the carbon pipe tip of the CNP buckles when pushed against the wall of a glass pipette and recovers its initial shape once the force is removed. (b) From top to bottom: a CNP penetrates through the membrane of a smooth muscle cell. The cell is held in place by glass micropipette aspiration. Scale bars, 15 µm. (Reprinted with permission from IOP Publishing) | |

| Several research groups have developed carbon nanotube and carbon pipe-based tools with similar intentions although these tools are difficult to manufacture. In contrast, the scalable fabrication method of the UPenn team allows for hundreds of probes with consistent nanoscale dimensions to be fabricated concurrently. Schrlau describes the process: | |

| "The inner bore of quartz capillaries are filled with a catalyst solution, allowed to air dry, and then pulled into fine-tipped micropipettes. Carbon is selectively deposited on the catalyzed surface by chemical vapor deposition (CVD). The thickness of the carbon film is controlled by varying the CVD time. The tip of the micropipette is then wet-etched to remove the quartz exterior and expose a short length of the interior carbon pipe. The wet etching time and temperature dictate the length of the exposed carbon pipe. Further reduction in tip outer diameters can be achieved by etching the outer diameter of the carbon pipe by plasma oxidation, resulting in carbon pipes with outer diameters ranging from 10?s to 100?s of nanometers. The final product is a glass capillary lined with a continuous carbon film along its interior and a nanoscale carbon pipe extending from its end." | |

| Apart from the unique advantage of being able to concurrently use the CNP as a nano-injector and a nano-electrode, Schrlau points out that there are several other promising potential applications for CNPs: 1) nanoscale biosensors – carbon can be functionalized with proteins, etc. for specific detection of analytes; 2) Sample holders for Electron Microscopy – the electron-transparent properties of CNPs enable them to hold biological samples in scanning or transmission EMs. | |

| In future work the researchers will focus on measuring cell membrane potentials concurrently with microinjection and on developing arrays of CNPs to simultaneously interact with a large number of cells. | |

| "I believe the biggest challenge in the nanosurgery tool field will be to go beyond the proof-of-concept, tool development stage into the utilization stage" says Schrlau. "This includes finding the appropriate collaborations across engineering, life science, and medical disciplines to, among other things, study how cells respond with their use (i.e., toxicity studies) and compare the tools to current (or traditional) technologies." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.