| Posted: Apr 05, 2006 | |

Electrochemical probes with nanometer dimensions |

|

| (Nanowerk News) Researchers in Finland and The Netherlands demonstrated that it is possible to grow and wire a single platinum nanoparticle using a single-walled carbon nanotube (SWNT), thus providing a bottom-up approach to building nanoelectrodes. Possible applications range from single-molecule detection to biomolecular sensors for medical diagnostics, and real-time monitoring of cell exocytosis. | |

| Dr. Bernadette Quinn, an Academy of Finland Research Fellow and working at the Lab of Physical Chemistry and Electrochemistry at Helsinki University of Technology explained to Nanowerk: "Microelectrodes are being applied to an ever increasing number of new applications in areas such as miniaturized analytical sensors, microfluidics and electrochemical imaging. There is considerable interest in scaling down the electrode dimensions another three orders of magnitude to the nanometer scale. However, nanoelectrodes have proven to be extremely challenging to prepare and this has hampered progress in this field." | |

| Most commonly, top-down approaches have been used for electrode fabrication, where a wire is etched to a sharp point and the whole surface, except the point, coated with an insulating material. More recently, SWNTs sputter-coated with metal have been used in place of an etched wire. | |

| The researchers exlpain that these approaches have focused on the preparation of nanoelectrodes suitable for use as probes in scanning electrochemical microscopy and are not compatible with either chip-based sensor applications or scale up. In principle, though, this limitation can be overcome with a nanofabrication-based approach. | |

| Quinn, together with Dr. Serge Lemay demonstrated an alternative bottom-up approach that was reported in the March 7, 2006 online edition of Advanced Materials with the title "Single-Walled Carbon Nanotubes as Templates and Interconnects for Nanoelectrodes" | |

| Lemay is one of the leaders of the Molecular Biophysics group in the Kavli Institute of NanoScience at Delft University of Technology in The Netherlands where some of his research deals with novel electrochemical probes. | |

| "We demonstrate a bottom-up approach for nanoelectrode fabrication that is compatible with chip-based sensor applications" says Quinn. "With our method, the nanoelectrode is formed in situ by the electrodeposition of a noble metal nanoparticle at the exposed end of a single-walled carbon nanotube." | |

| "The nanotube end serves as a nanometer-sized template for nanoparticle electrodeposition, while the tube itself is a nanometer wire to interface the deposited nanoparticle with macroscopic leads" Quinn says. | |

| "SWNTs are wires 1–5 nanometers in diameter and up to centimeters in length. The combination of this aspect ratio, excellent conductivity and chemical inertness makes them ideal interconnects between the micro and nano scale" Lemay says. | |

| |

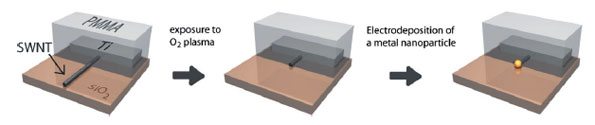

| Schematic illustrating the fabrication process. Due to the poly(methyl methacrylate) (PMMA) mask, only the exposed SWNTs are removed by the oxygen plasma. As the PMMA layer insulates both the sidewalls and Ti contact, only the SWNTends embedded in the PMMA wall are electrochemically active. Metal nanoparticles can be electrodeposited at the exposed end yielding a metal nanoparticle that is electrically connected to the Ti contact by the SWNT under the PMMA layer. (Reprinted with permission from Wiley) | |

| Quinn concludes: "Summarizing, we demonstrated that it is possible to grow and wire a single platinum nanoparticle using a SWNT. The nanoelectrode fabrication method outlined here is general and can easily be adapted to generate single particle electrodes or arrays." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.