| Posted: Jun 19, 2015 | |

A magnetic-assisted, self-healing supercapacitor |

|

| (Nanowerk Spotlight) Wearable electronics will increasingly become thinner and flexible. They will be integrated into our clothes and sensor band-aids, even tattoos. One problem that arises with these ever thinner devices is that as their thickness shrinks, their robustness and resistance to stress from bending and deformation decreases as well. This may cause partial or permanent mechanical device failure. | |

| Researchers in China have developed a potential solution to this problem by designing an electrically and mechanically self-healable yarn-based supercapacitor. The team of Dr. Yan Huang and Mr. Yang Huang et al, led by Chunyi Zhi, an assistant professor in the Department of Physics & Materials Science at the City University of Hong Kong, reported their findings in the June 1, 2015 online edition of ACS Nano ("Magnetic-Assisted, Self-Healable, Yarn-Based Supercapacitor"). | |

| "Self-healing of a device is different from material self-healing because the devices contain electronic circuits," Zhi explains to Nanowerk. "Therefore, self-healing of a device includes materials self-healing plus alignment of electrodes, which is very difficult but essential." | |

| Zhi and his team have come up with the idea of using magnetic force to assist alignment of electrodes in a circuit, facilitating self-healing of the whole device. | |

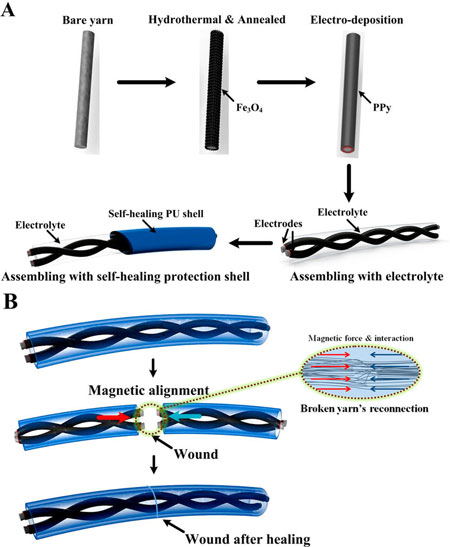

| To realize this idea, they designed and fabricated an electrically and mechanically self-healable yarn-based supercapacitor by wrapping magnetic electrodes with a self-healing carboxylated polyurethane shell. | |

| The magnetic force assists the broken electrode's reconnection through magnetic alignment, which benefits the recovery of electrochemical performance after self-healing. Meanwhile, the carboxylated polyurethane shell is responsible for the outstanding mechanically self-healing performance, which is crucial to practical applications. | |

|

|

| (A) Design and manufacturing process flow of the magnetic-assisted self-healable supercapacitor. Fe3O4 nanoparticles anchor on the surface of the yarn by a microwave-assisted hydrothermal method. The processed yarn is annealed to ensure the magnetic particles anchor on the yarn tightly. To achieve a better electrochemical performance, a layer of PPy is electrodeposited on the annealed yarn. Finally, two yarns as a set of electrodes are assembled with a solid electrolyte and a self-healing shell to form a self-healing supercapacitor. (B) Schematic illustration of the supercapacitor's self-healing process. The magnetic alignment could assist the reconnection of the fibers in the broken yarn electrodes when they are brought together, as shown in the inset image. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The researchers utilized a special conductive yarn that they previously fabricated for a large-sized supercapacitor textile, and which can withstand various chemical processes, including hydrothermal synthesis and electrochemical deposition ("From Industrially Weavable and Knittable Highly Conductive Yarns to Large Wearable Energy Storage Textiles"). | |

| Compared with conventional planar-like or large wire-like structures, the reconnection of a broken yarn-based electrode is much more challenging, since it is composed of multiple tiny fibers (diameter < 20 µm). Zhi notes that it is unrealistic to reconnect each of the tiny broken fibers contained in the yarn accurately by visual inspection. Meanwhile, in order to achieve the restoration of electrochemical performance after damage, a good reconnection of the broken yarn in the supercapacitor is essential. | |

| An essential design aspect of the team's self-healable supercapacitor is the coating of the magnetic electrodes in a self-healable polyurethane shell. Once the supercapacitor is subjected to mechanical damage, the external movement of the self-healing shell brings the broken areas into contact and realizes mechanical self-healing autonomically, while the broken magnetic electrodes are electrically reconnected and aligned thanks to the magnetic interaction between the fibres of the yarn which guides the reconnection process. | |

| These synergistic effects between the self-healing shell and the magnetic electrodes enable the device to restore its configuration and electrochemical performance. | |

| "On one hand, our device is a yarn-based energy storage device," says Zhi. "Therefore, it will be easily integrated with other traditional fabrics as wearable power supply to power wearable electronics. On the other hand, with its outstanding self-healing performance, the device could be endowed with extreme long lifespan in practical applications." | |

| This work may also benefit the design and fabrication of other self-healable and wearable electronics, for example, self-healing sensor. | |

| The team is now working on improving the energy density of their supercapacitor as an energy storage device. In addition, they will try to integrate the technologies developed in this work into other fields to impart more wearable devices with self-healing capabilities. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|