| Posted: Apr 07, 2006 | |

Creating differently shaped and sized hollow nanospheres from a single template |

|

| (Nanowerk News) Polymeric hollow nanospheres with high stability and controllable permeability have interesting potential applications associated with the controlled release of encapsulated active ingredients (e.g., drugs, vaccines, antibodies, hormones, pesticides, and fragrances) under well-defined conditions. Researchers in Singapore are now fabricating hollow nanostructures with different shapes using a single template. This solves the problem of the shells of differently shaped hollow nanostructures having different properties. | |

| Current techniques applied to fabricating hollow nanospheres, such as such as the layer-by-layer deposition technique, in situ polymerization on template particles, pH-induced micellization of grafted copolymer, and core-free-template strategy, can only be used to prepare hollow spheres with a specific size range. It also was not possible to fabricate hollow nanostructures with different shapes using a common template. | |

| It seems that the properties of the shell of hollow nanospheres strongly depend on the fabrication process and the difference in the nature of the shells holds the key to the properties exhibited by the hollow nanostructures. This creates a problem if one wants to fabricate differently shaped hollow structures with identical shell properties. | |

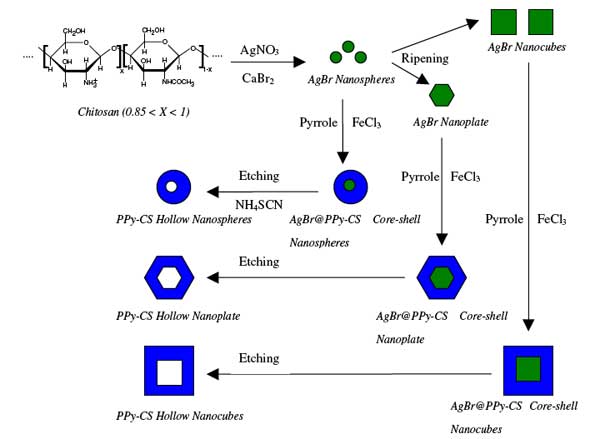

| Researchers in Singapore found a solution to this problem. Professor Hardy Sze On Chan explains to Nanowerk: "We describe a facile method for the fabrication of polypyrrole-chitosan (PPY-CS) hollow nanostructures of different sizes and shapes by using silver bromide as a single template material. This method is easy to manipulate and all the materials used are low cost and readily available. Control over particle dimensions (e.g. core shape, core diameter and shell thickness) can be achieved easily." | |

| Chan, together with first author Daming Cheng and co-author Habing Xia, all from the National University of Singapore, describe their recent findings in an article titled "Fabrication of polymeric hollow nanospheres, hollow nanocubes and hollow plates" published in the March 28, 2006 issue of Nanotechnology. | |

| |

| Schematic illustration of the preparation of PPy–CS hollow nanostructures. (Reprinted with permission from IOP Publishing Ltd.) | |

| "Three polymeric hollow nanostructures, PPy-CS hollow nanosphere, hollow nanocube and hollow plate can be prepared using this template material" says Chan. "The same template material and the same fabrication procedure afford the shell of these hollow structures similar permeabilities. A unique feature of the PPy-CS hollow nanostructures is that the permeability of the shell can be controlled by the pH of the medium." | |

|

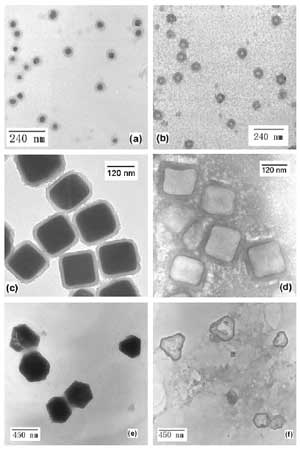

TEM images of (a) AgBr@PPy–CS nanosphere; (b) PPy–CS hollow nanosphere; (c) AgBr@ PPy–CS nanocube; (d) PPy–CS hollow nanocube; (e) AgBr@PPy–CS nanoplate; and (f) PPy–CS hollow nanoplate. For (c), the AgBr emulsion was ripened (heated at 60°C for 1 h) before the polymerization. (Reprinted with permission from IOP Publishing Ltd.) |

| The research in Chan's group is directed towards the synthesis, characterization and applications of functional conducting and conjugated polymers. The team has worked specifically on core-shell and hollow nanospheres since 2002. In 2004, they first reported their results in Langmuir "Facile Fabrication of AgCl@Polypyrrole-Chitosan Core-Shell Nanoparticles and Polymeric Hollow Nanospheres". In 2005, they published a subsequent work in Chemistry of Materials "Novel Method for the Preparation of Polymeric Hollow Nanospheres Containing Silver Cores with Different Sizes". | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.