| Posted: Sep 23, 2015 | |

Scientists make nanofibers with a hairbrush |

|

| (Nanowerk Spotlight) Polymer nanofibers are used in a wide range of applications such as the design of new composite materials, the fabrication of nanostructured biomimetic scaffolds for artificial bones and organs, biosensors, fuel cells or water purification systems. | |

| "The simplest method of nanofiber fabrication is direct drawing from a polymer solution using a glass micropipette," Alexander Tokarev, Ph.D., a Research Associate in the Nanostructured Materials Laboratory at the University of Georgia, tells Nanowerk. "This method however does not scale up and thus did not find practical applications. In our new work, we introduce a scalable method of nanofiber spinning named touch-spinning." | |

| In a new paper in the September 23, 2015 online edition of Advanced Materials ("Touch- and Brush-Spinning of Nanofibers"), a team of researches from the University of Georgia, Princeton University and Oxford University describe a simple controllable set-up for drawing single filament nanofibers from polymer solutions or melts using a rotating rod or a set of rods (round brush). | |

| "Our method can be used to produce 3D tissue scaffolds by winding nanofibers onto spools of different shapes and dimensions and depositing cells of interest at the same time," explains Tokarev, who is the paper's first author. | |

|

|

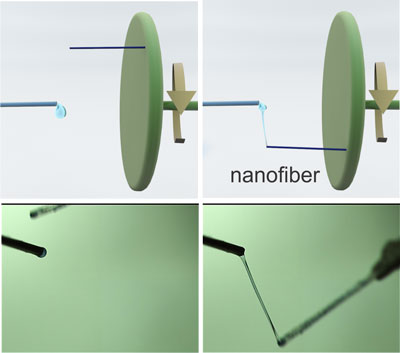

| Figure 1: Touchspinning of nanofibers. (Image: Dr. Tokarev, University of Georgia) | |

| The fiber drawing is conducted with a very simple spinning set-up (see Figure 1 above). | |

| The new method, which the scientists named touch-spinning, has excellent control over the fiber diameter and is compatible with all kinds of polymeric materials, polymer melts and solutions, polymer composite materials, and biopolymers. | |

| The technique works as follows: A glass rod is glued to a rotating stage, whose diameter can be chosen over a wide range of a few cm to more than one meter. A polymer solution is supplied, for example, from a needle of a syringe pump that faces the glass rod. The distance between the droplet of polymer solution and the tip of the glass rod is adjusted so that the glass rod contacts the polymer droplet as it rotates. | |

| Following the initial 'touch', the polymer droplet forms a liquid bridge. As the stage rotates the bridge stretches and fiber length increases, with the diameter decreasing due to mass conservation. | |

| The team showed that the diameter of the fiber can be precisely controlled down to 40 nm by the speed of the stage rotation. | |

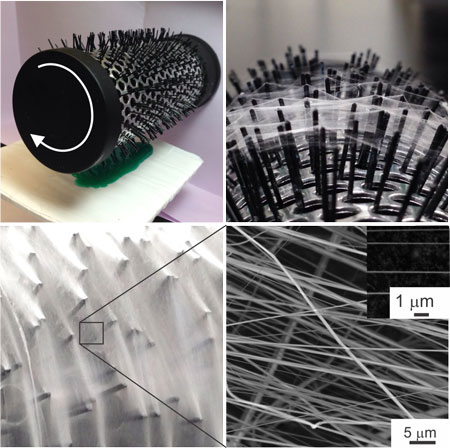

| "The method can be easily scaled-up, as demonstrated in our paper, by using a round hairbrush composed of 600 filaments," says Tokarev. "When the rotating brush touches the surface of a polymer solution, the brush filaments draw many fibers simultaneously producing hundred kilometers of fibers in minutes (see Figure 2). | |

| The drawn fibers are uniform since the fiber diameter depends on only two parameters: polymer concentration and speed of drawing. | |

|

|

| Figure 2: Brush-spinning of nanofibers. (Reprinted with permission by Wiley-VCH Verlag)) | |

| As the team points out, one important aspect of the method is the drawing of single filament fibers. | |

| These single filament fibers can be easily wound onto spools of different shapes and dimensions so that well aligned one-directional, orthogonal or randomly oriented fiber meshes with a well-controlled average mesh size can be fabricated using this very simple method. | |

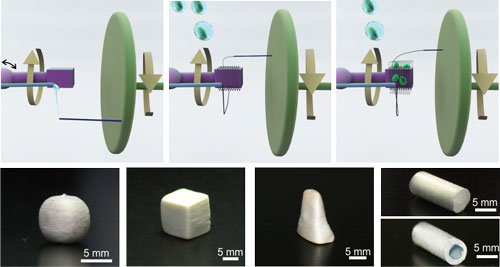

| "Owing to simplicity of the method, our set-up could be used in any biomedical lab and facility," notes Tokarev. "For example, a customized scaffold by size, dimensions and other morphologic characteristics can be fabricated using donor biomaterials." (see Figure 3). | |

|

|

| Figure 3: Preparation of 3D scaffolds of different shapes by touch-spinning and simultaneous spraying of cells. (Image: Dr. Tokarev, University of Georgia) (click on image to enlarge) | |

| "The spinning set-up is so simple and inexpensive that it can be fabricated as a single use device for bioengineering labs and health care providers, " concludes Tokarev. "Other examples include, but are not limited to, filtration technologies and fibrous non-wettable coatings of textiles." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|