| Posted: Dec 15, 2015 | |

Nanocurve-based sensor reads facial expressions |

|

| (Nanowerk Spotlight) One of the challenges of fabricating flexible electronics is the trade-off between a material's conductivity and its high flexibility and adaptability. Exploring feasible methods for guiding conducting or semiconducting nanomaterials into elastomeric matrices will be key to further progress in this area. | |

| A promising approach has just been reported ("Nanoparticle Based Curve Arrays for Multirecognition Flexible Electronics") by scientists in China, who have developed a facile printing strategy to assemble silver nanoparticles into micro- and nano-curve structures via a pillar-patterned silicon template. | |

| The curves with various tortuosity morphologies have differential resistive strain sensitivity, which can be integrated into a multi-analysis flexible sensor to perform recognition of complex human facial expressions. | |

| "The realization of of recognizing multiple facial expressions or eyeball movements based on integration analysis of silver nanoparticle based curved array sensors is a real breakthrough for the next generation of wearable sensors, which has already been indicated in a recent review paper ("Recent Progress in Electronic Skin")," Yanlin Song, a professor at the Institute of Chemistry, Chinese Academy of Sciences, and Director of Key Laboratory of Green Printing, tells Nanowerk. | |

|

|

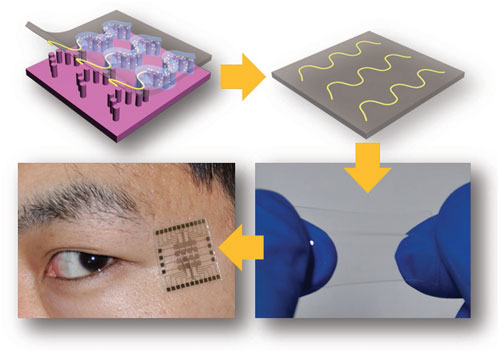

| The schematic illustration of the nanoparticle curve array printed to flexible electronic devices and adopted to multi analysis for skin micromotion sensing. Nanoparticle curve arrays were printed on the PDMS substrate by pillar-patterned template induced printing with sliver nanoparticle ink. These flexible electronic sensors can be directly attached to human facial skin, and perform real-time multi analysis for skin micromotion monitoring. (Reprinted with permission by Wiley-VCH Verlag) | |

| Avoiding traditional methods that involve complex etching processes and toxic by-products, Song's team realized the printable fabrication of elastomeric matrices with arbitrary curve patterns and large scale output with high resolution at the macro- and nanoscale. | |

| "After investigating the dependence of curved nanoparticle assembly arrays on the pattern on the template, we can achieve different complex curves by designing the templates accordingly," explains Song. | |

| Compared with other flexible sensors, the team's nanoparticle curve sensor with the characteristics of adjustable resistance responses to strain is a real breakthrough for wearable sensors. | |

| The curved pattern fabrication method manipulates the nanoparticle ink to form diverse curved patterns. The scientists point out that, during the assembly process of the nanocurves, the liquid surface tension and viscosity must be well controlled, which, in combination with well-designed pillar templates, is key to yielding regularly arranged curve arrays. | |

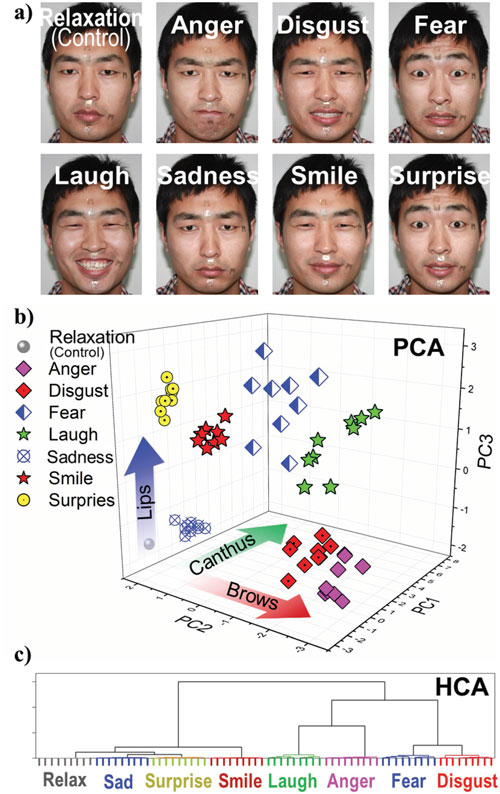

| To test their arrays, the researchers fabricated microelectrode sensors which they used to measure facial expressions. They attached the sensors to different locations on the face – the upper eyelid, lower eyelid, and canthus – to investigate small strain sensing for eight types of facial expressions (anger, disgust, fear, laughter, sadness, smiling, surprise, and relaxed as control). | |

|

|

| Electronics discriminant analysis of eight facial expression on nanoparticle curves-based strain sensors array and rational analysis. a) The nanocurves array chips were attached at six selective positions on facial skin, which included the characteristic muscle groups. b) 3D representation of PCA result shows a clear clustering of the eight different facial expressions as analytes. c) HCA gives the similarity clustering of the analytes based on the characteristic muscle movement variation trend. (Reprinted with permission by Wiley-VCH Verlag) | |

| "Our nanoparticle curve-based strain sensors can achieve detailed monitoring of complex micro muscle group movements," notes Song. "Actually, the most remarkable application will contribute to skin micromotion manipulation auxiliary apparatuses for paraplegics and quadriplegics." | |

| In the next stage of their research, Song's team will use this effective and simple printable method to realize three-dimensional (3D) nanomaterial assembly. Sensors based on 3D structures will show anisotropic differential responses to external stimuli, which provide new opportunities for the fabrication of intelligent electronic skins. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|