| Posted: Jan 25, 2008 | |

Easily fabricated microscale fish bowls as a new class of payload carriers |

|

| (Nanowerk Spotlight) Hollow polymeric micro- and nanoparticles have numerous existing and many anticipated applications in drug delivery, ranging from the controlled release of drugs, cosmetics, inks, pigments or chemical reagents to the protection of biologically active species, and removal of pollutants. Encapsulation also allows drug targeting via cell and tissue-specific ligands. There is a variety of methods available for synthesis of polymer microspheres with hollow interiors. The hollow particles are most commonly prepared by coating the surfaces of colloidal templates with thin layers of the desired material (or its precursor), followed by selective removal of the templates by means of calcination or chemical etching. For polymers, methods such as emulsion polymerization, phase separation, cross-linking of micelles and self-assembly have also been demonstrated for generating hollow structures. The hollow polymer particles produced by these methods present either a closed-core-shell structure or many small pores on their surface. However, these synthetic approaches present limitations on the choice of polymers that can be produced as hollow microspheres. Also, the number, size and shape of the surface pores can not be easily manipulated. When these materials are used for encapsulation-related applications, the encapsulation of the desired functional materials is usually too slow and/or too labor-intense. These problems have motivated scientists to develop the synthesis of a new class of polymer microspheres, which they called microscale fish bowls. Their unique feature consists in the presence of one big pore on their surface that allows easy and fast diffusion of a functional material to be encapsulated. Another new feature is that this newly developed method presents no limitations on the choice of polymers that can be produced as microscale fish bowls. | |

| "The scientific core of our findings is about the establishment of a simple and versatile method for preparing polymer microscale fish bowls, i.e., polymer hollow microspheres containing engineered pores on their surfaces" Prof. Younan Xia tells Nanowerk. "Our approach is not limited to any particular polymer system, i.e., it can be applied to a variety of amorphous, semi-crystalline and biodegradable polymers. The size, number and shape of the pores located onto the surface of the microscale fish bowls can also be controlled based on the experimental conditions. Moreover, the pores can be closed via thermal or solvent-induced annealing process, making this system very attractive for applications in controlled release. In this case, the functional material to be released can be easily loaded and encapsulated through the pores. This strategy provides a useful platform for encapsulation and controlled release for a wealth of functional materials." | |

| Conventionally, the hollow particles used for such an application possess either a completely close-shell or a multi-porous surface in which the number and shape of the many pores cannot be easily controlled. In these systems, the functional material to be encapsulated must be introduced by diffusing through the shell, which is usually a slow and labor-intense process. | |

| Consequently, as Xia points out, the development of the microscale fish bowl represents an important advance in this area, as the presence of one big pore that can be easily closed via mild heating or solvent treatment allows to achieve fast and effective encapsulation, eliminating the problems observed in previous systems. | |

|

|

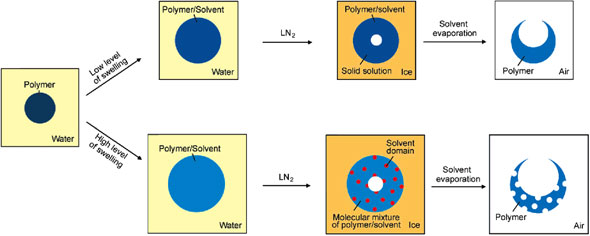

| Schematic illustrating the formation of microscale fish bowls from pre-synthesized polymer beads. Depending on the amount of solvent used to swell the latex bead, the final bowl may have different porous structures: there is only one big opening in the surface of the bowl for swelling at a relatively low level (upper panel), and there is one big opening plus many small holes when the level of swelling is increased (lower panel). (Reprinted with permission from American Chemical Society) | |

| Xia, the James M. McKelvey Professor in the Department of Biomedical Engineering at Washington University in St. Louis, together with collaborators from Yonsei University in South Korea, has published his findings in a recent paper in Langmuir ("Microscale Fish Bowls: A New Class of Latex Particles with Hollow Interiors and Engineered Porous Structures in Their Surfaces"). | |

| In previous work published in Nature Materials, Xia and collaborators already demonstrated the production of hollow polymer particles with one big hole in the surface ("Polymer hollow particles with controllable holes in their surfaces"). Yet the microscale fish bowls developed in his new work allow easier and faster encapsulation of a functional material for controlled release applications. | |

|

|

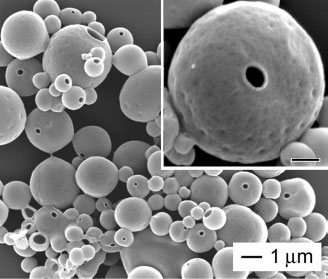

| SEM images of poly(methyl methacrylate) (PMMA) fish bowls prepared from emulsions containing toluene. The scale bar in the inset corresponds to 250 nm (Reprinted with permission from American Chemical Society) | |

| "We believe that these fish bowls can potentially present superior controlled release performances compared to the current polymer systems employed for controlled release" says Xia. "Moreover, our synthetic method is versatile: there is no limitation regarding the polymer system that can be synthesized as polymer microscale fish bowls. This characteristic is very important as it allows the production of different composition microscale fish bowls suitable for a wide variety of controlled release demands." | |

| The microscale fish bowls can be immediately used in a variety of encapsulation-related applications, such as the controlled release and delivery of drugs, contrast agents, cosmetics, inks, pigments, or chemical reagents, protection of biologically active species, and removal of wastes. | |

| The scientists have demonstrated two different routes for the fabrication of polymer capsules with controllable holes in their surfaces for both amorphous and semicrystalline polymers. | |

| "The first route requires the use of pre-synthesized latex beads and is mainly limited to a few amorphous polymers such as PS and PMMA" explains Xia. "The second route involves the use of an emulsion derived from a polymer solution. This route is more generic and can be directly applied to both amorphous and semicrystalline polymers, including those such as PCL and PLLA that are biodegradable." | |

| He notes that for both routes, the fish bowls may display different porous structures in their surfaces depending on the amount of solvent involved. "Interestingly, the dependence of the porosity and pore structure on the amount of solvent was found to be the same for both amorphous and semicrystalline polymers" he says. | |

| As the synthetic strategies have been developed, the future direction for research in this field would be concerned with the applications of the microscale fish bowls as carriers for controlled drug release, for example. Xia points out that the challenges that will need to be addressed before their ultimate application include the establishment of the best polymer for a specific drug-release system and the optimization of their performance by controlling the release mechanism to targeted cells and tissues. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.