| Posted: Jan 08, 2016 | |

Investigating fracture behavior of nanocrystalline Ni-W thin-films |

|

| (Nanowerk Spotlight) In the past couple of decades, nickel-tungsten (Ni-W) amorphous and nanocrystalline materials have been drawing more and more research interest due to the superior mechanical properties such as high hardness, good mechanical performance, and excellent corrosion resistance. | |

| Striving to enhance the mechanical performance of Ni-W thin film alloys, researchers from Lehigh University and University of California at San Diego have recently reported how the annealing temperature will influence the microstructure evolution and the fracture properties of Ni-W alloys. | |

| Wanjun Cao, lead author of a paper in Scripta Materialia ("Correlations between microstructure, fracture morphology, and fracture toughness of nanocrystalline Ni-W alloys") describing the recent work, says that a unique SEM in situ fracture toughness testing method discovered that trace amount of oxide streaks could be a key factor to determine the fracture mechanisms and fracture toughness of Ni-W alloys. | |

|

|

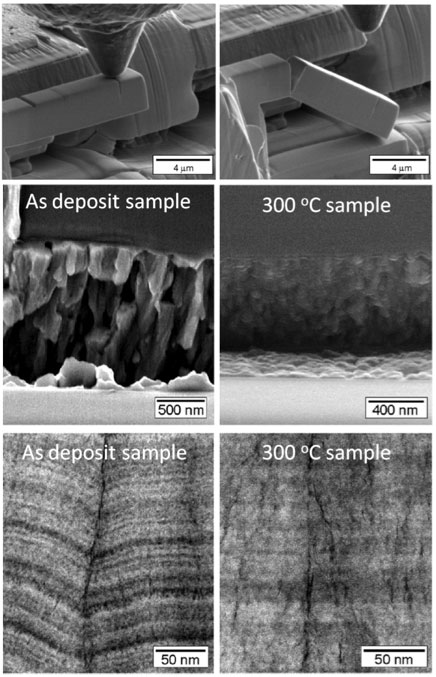

| Cantilever beam test configuration immediately (top left) before and (top right) after fracture. Top-down SEM views of the fracture surfaces (middle) and STEM-HAADF images (bottom) of the oxide streaks found in the as-deposited (left) and 300°C specimens (right). (Reprinted from Scripta Materialia 113, 84-88 (2016) with permission from Elsevier) | |

| Cao, now a research scientist with Baker Hughes Inc., was a graduate researcher in the Department of Materials Science and Engineering working in Prof. Richard Vinci's group. He worked on this project with collaborators, Chris Marvel, Denise Yin, Yuanyao Zhang, Patrick Cantwell, Martin Harmer and Jian Luo from Lehigh and UCSD. | |

| The scientists performed a SEM in situ micro-scale cantilever beam deflection test to investigate the fracture behaviors of Ni-W alloys with different thermal cycles and quantitatively reported the fracture toughness values. Atomic resolution aberration-corrected scanning transmission electron microscope (STEM) characterizations were utilized to correlate the microstructure and the mechanical properties. | |

| "Both the as deposit and 300 °C specimen were determined to be a single phase amorphous Ni-W," explains Cao. "The oxide streaks found in the as-deposited specimen were spaced approximately 200 nm apart, well-defined, continuous, and aligned perpendicular to the film surface, whereas the streaks found in the 300 °C specimen were closer packed and branched." | |

| He points out, that it is not surprising that the undulating morphology of the deposited sample is due to the crack following weak vertical oxide trails, and the more uniform fracture surface of the 300 °C specimen is due to the more closely-spaced, discontinuous nature of the branched oxides. | |

| "As a result" says Cao, "the fracture toughness of the Ni-W drops about 15% after annealing at 300 °C due to the easier fracture propagation path. The role of the oxide streak in the Ni-W alloy fracture process has been overlooked by previous research since it is very difficult to detect those streaks with conventional characterization methods." | |

| In contrast with the amorphous specimens, the 700 °C specimen fracture surface exhibited an intergranular fracture path which may contribute to a 25% increase of the fracture toughness. | |

| This suggests that the annealing of the as-prepared Ni-W thin films at higher temperatures does not change fracture toughness in a simple way: the changes depend on the nature of fine-scale microstructure and impurities in the Ni-W alloy. | |

| In addition, this study provides a very convenient and practical method to quantitatively measure the fracture toughness of other amorphous or nanocrystalline material systems. | |

| The micro-scale cantilever beam deflection testing approach was initially developed by Cao and Vinci in an earlier study published in Scripta Materialia ("Direct correlations between fracture toughness and grain boundary segregation behavior in ytterbium-doped magnesium aluminate spinel") which first reported the doping effects on the fracture toughness of a ceramic single grain boundary. | |

| Currently, this research is partially supported by the ONR-MURI program(grant no. N00014-11-0678) aiming at creating 'designer' materials with unique property sets and/or vastly improved specific properties and performance for application in materials systems used in ships, submersibles, aircraft, land-based transport and hypersonic vehicles for the U.S. Department of Defense. | |

|

Source: Lehigh University

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|