Nanocrystalline Materials: Unleashing the Power of Nanoscale Grains

What are Nanocrystalline Materials?

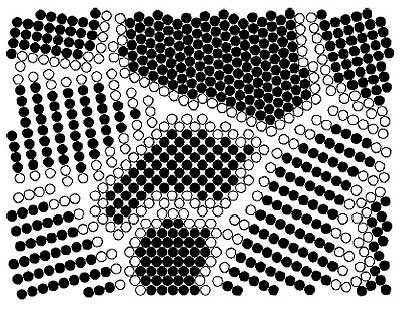

Nanocrystalline materials are a class of materials characterized by their extremely small grain sizes, typically less than 100 nanometers. These materials exhibit unique properties and behaviors that differ significantly from their bulk counterparts due to the high volume fraction of grain boundaries and interfaces at the nanoscale.

Structure and Synthesis of Nanocrystalline Materials

Nanocrystalline materials are characterized by their nanoscale grain sizes, typically ranging from a few nanometers to around 100 nanometers. These small grains are separated by grain boundaries, which are interfaces between differently oriented crystalline regions. The high volume fraction of grain boundaries in nanocrystalline materials can account for up to 50% of the total volume, leading to a significant influence on the material's properties.

Various synthesis methods can be employed to produce nanocrystalline materials, including:

- Mechanical alloying: A high-energy ball milling process that involves the repeated fracturing and cold welding of powder particles to create nanocrystalline structures.

- Severe plastic deformation: Techniques such as equal channel angular pressing (ECAP) and high-pressure torsion (HPT) that introduce intense plastic strain to refine the grain structure.

- Electrodeposition: A process that involves the deposition of nanocrystalline coatings or films onto a substrate using an electrolytic cell.

- Sol-gel processing: Sol-gel processing is a wet-chemical method that involves the hydrolysis and condensation of precursor solutions to form nanocrystalline powders or thin films.

Properties and Advantages of Nanocrystalline Materials

Nanocrystalline materials exhibit a range of unique properties that make them attractive for various applications:

Enhanced Mechanical Properties

Nanocrystalline materials often demonstrate exceptional mechanical properties, such as high strength, hardness, and wear resistance. The small grain sizes and high density of grain boundaries hinder dislocation motion, leading to strengthening effects like the Hall-Petch relationship. Additionally, the large volume fraction of grain boundaries can promote grain boundary sliding, resulting in improved ductility and toughness.

Improved Functional Properties

Nanocrystalline materials can exhibit enhanced functional properties compared to their bulk counterparts. For example, nanocrystalline ceramics and semiconductors can show increased electrical conductivity due to the high density of grain boundaries that facilitate charge transport. Nanocrystalline magnetic materials can display enhanced coercivity and magnetic anisotropy, making them suitable for high-performance permanent magnets and data storage applications.

Increased Surface Area and Reactivity

The small grain sizes in nanocrystalline materials result in a high surface-to-volume ratio, which can significantly enhance their surface reactivity and catalytic properties. This makes nanocrystalline materials attractive for applications in catalysis, sensors, and energy storage devices like batteries and fuel cells.

Applications of Nanocrystalline Materials

Nanocrystalline materials find applications in various fields, leveraging their unique properties:

Structural Applications

Nanocrystalline metals and alloys are used in structural applications that require high strength, wear resistance, and fatigue resistance. Examples include nanocrystalline coatings for cutting tools, bearings, and gears, as well as lightweight, high-strength components for aerospace and automotive industries.

Functional Devices

Nanocrystalline materials are employed in functional devices such as solar cells, thermoelectric generators, and sensors. Nanocrystalline semiconductors and oxides can enhance the efficiency of solar cells by improving charge transport and light absorption. Nanocrystalline thermoelectric materials exhibit higher thermoelectric figures of merit due to reduced thermal conductivity and enhanced electrical conductivity.

Energy Storage and Conversion

Nanocrystalline materials play a crucial role in energy storage and conversion devices like batteries, supercapacitors, and fuel cells. Nanocrystalline electrodes with high surface areas and short diffusion paths enable faster charge/discharge rates and higher energy densities. Nanocrystalline electrolytes and membranes can improve ionic conductivity and selectivity in these devices.

Challenges and Future Perspectives

Despite the numerous advantages of nanocrystalline materials, there are still challenges to overcome for their widespread application. One of the main challenges is the control and stability of nanocrystalline structures during processing and service. Grain growth and coarsening can occur at elevated temperatures, leading to the loss of nanocrystalline properties. Strategies like grain boundary engineering, alloying, and composite design are being explored to enhance the thermal stability of nanocrystalline materials.

Future research in nanocrystalline materials will focus on developing novel synthesis methods, understanding the structure-property relationships at the nanoscale, and designing materials for specific applications. The integration of computational modeling and machine learning techniques will accelerate the discovery and optimization of nanocrystalline materials. Additionally, the combination of nanocrystalline materials with other nanoscale building blocks, such as nanoparticles, nanotubes, and graphene, will open up new avenues for multifunctional and hierarchical materials with tailored properties.

Further Reading

Journal of The Minerals, Metals & Materials Society, Nanocrystalline metals for structural applications

Materials Today Advances, Amorphous–nanocrystalline alloys: fabrication, properties, and applications