Understanding Sol-Gel Synthesis in Nanotechnology

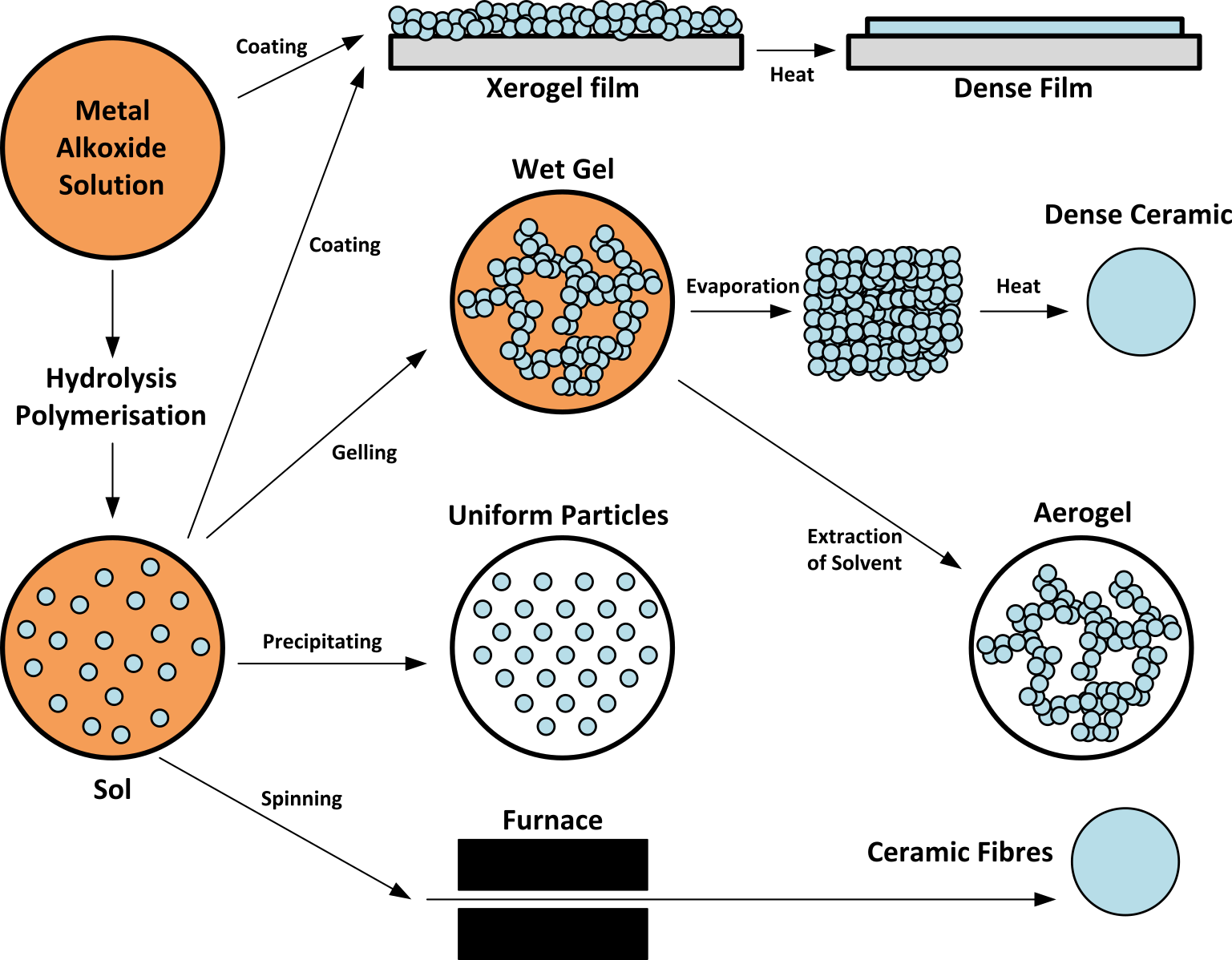

Definition: Sol-gel synthesis is a chemical process used to produce solid materials from small molecules. This method enables the creation of nanoscale materials with unique properties, applicable in various fields such as optics, electronics, and materials science. The process involves the transition of a system from a liquid 'sol' (a colloidal solution) into a solid 'gel' phase.

Process and Mechanism

The sol-gel synthesis process begins with the preparation of a sol, where metal or metalloid precursors are dissolved in a solvent. These precursors undergo hydrolysis and polymerization reactions, leading to the formation of a network of interconnected particles or polymers, transitioning into a gel. The gel contains both a solid network and a liquid phase, which can be removed through drying, yielding a porous material. Further heat treatment can densify the material into a glass or ceramic.

Advantages of Sol-Gel Synthesis

- Low Temperature Processing: One of the significant benefits of sol-gel synthesis is its ability to produce materials at relatively low temperatures compared to traditional ceramic processing methods. This characteristic is crucial for incorporating organic or other temperature-sensitive components.

- Versatility: The sol-gel process is extremely versatile, allowing for the doping of materials with various additives to tailor physical, chemical, and optical properties. This flexibility enables the creation of a wide range of materials, including coatings, fibers, thin films, and nanoparticles.

- Purity and Homogeneity: Materials produced via sol-gel synthesis are often of high purity and homogeneity due to the molecular mixing of precursors. This aspect is essential for applications requiring precise material properties.

- Control Over Microstructure: The process offers control over the microstructure of the final product, including porosity, pore size, and surface area. These characteristics are critical for applications in catalysis, filtration, and as substrates for further chemical modifications.

Applications of Sol-Gel Synthesis

- Optical Materials: Sol-gel synthesis is used to produce high-purity glass and ceramic materials for lenses, mirrors, and optical fibers. The ability to precisely control the refractive index and transparency is particularly beneficial for these applications.

- Coatings: Protective and functional coatings for metals, glass, and polymers are often created using sol-gel techniques. These coatings can provide scratch resistance, anti-reflection, hydrophobicity, or other desired surface properties.

- Catalysts and Sensors: The sol-gel process can produce porous materials that serve as catalysts or sensor substrates. The high surface area and tailored chemical functionality enable efficient catalytic reactions and sensitive detection of chemical species.

- Biomedical Applications: Sol-gel derived materials are used in drug delivery systems and bioactive coatings for implants. The controlled release of therapeutic agents and the promotion of bone growth on implants are significant areas of research.

Challenges and Considerations

- Cracking During Drying: The removal of the liquid phase from the gel can lead to cracking and structural defects. Careful control of the drying process is necessary to minimize these effects.

- Reproducibility: The sol-gel process can be sensitive to the precise conditions and precursor materials used, potentially leading to issues with reproducibility between batches.

Recent Innovations in Sol-Gel Technology

Recent advancements in sol-gel technology include the development of hybrid organic-inorganic materials, aerogels with extremely low densities and high surface areas, and the application of sol-gel chemistry to create novel nanostructured materials for energy storage, conversion, and environmental remediation.

Environmental Impact and Sustainability

The sol-gel process, with its low-temperature processing and ability to incorporate bio-based precursors, offers opportunities for creating sustainable materials. Researchers are focused on reducing the environmental footprint of materials production through this technology.

The integration of sol-gel synthesis in nanotechnology highlights its importance in advancing materials science. By enabling the design and creation of materials with tailored properties, sol-gel synthesis contributes significantly to innovations in numerous industries.

Further Reading

Advances in Materials Science and Engineering, Nanomaterial by Sol-Gel Method: Synthesis and Application

Chemical reviews, The sol-gel process