| Posted: May 12, 2016 | |

Direct writing with highly conductive graphene inks |

|

| (Nanowerk Spotlight) Numerous research efforts already have demonstrated the feasibility of fabricating graphene-based electronics through high-throughput ink printing strategies (see for instance: "Inkjet printing of graphene for flexible electronics"). However, the electrical conductivity of the printed ink patterns is far from satisfactory. | |

| In inkjet printing of graphene, however, the diameter of the printing nozzle regularly defaults to be tens of micrometers; thus, increased graphene sheet sizes beyond the safe range of the nozzle could restrict the printing fluency and cause clogging. | |

| "Generally, achieving satisfactory results it is a trade-off between the sizes of the graphene sheets and the chosen printing strategies," Yanlin Song, a professor at the Institute of Chemistry, Chinese Academy of Sciences, and Director of Key Laboratory of Green Printing, tells Nanowerk. "Direct ink writing offers an attractive way to break the routine and meet the printability with the demanding sheet sizes. The nozzles' diameters range from sub micrometer to millimeter scale to accommodate the inks. More importantly, the extrusion-based procedure plays a crucial role in directing the orientation of graphene sheets to pass through the nozzle during printing." | |

| In their new work, reported in the April 28, 2016 online edition of ACS Applied Materials & Interfaces ("Flexible Circuits and Soft Actuators by Printing Assembly of Graphene"), Song's group presents the assembly of graphene sheets with large size through direct-write printing strategy. | |

|

|

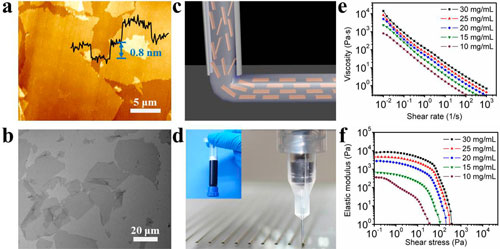

| Direct writing with giant graphene oxide (GGO) inks. (a) AFM image of GGO deposited on mica. (b) SEM image of GGO deposited on silicon. (c) Schematic diagram illustrating the alignment of GGO during the printing process. (d) Optical image of the printing process and the modified ink with a concentration of 20 mg/mL in a 3 cm3 barrel (inset). (e and f) Viscosity and shear elastic modulus as a function of the shear rate for GGO inks of varying concentrations (10, 15, 20, 25, and 30 mg/mL). (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The team fabricated graphene patterns with ordered micro-structure and excellent conductivity. To do this, they realized the assembly of giant graphene oxide (GGO) sheets during the printing process. The synergetic effect of printing-induced orientation and evaporation-induced interfacial assembly facilitated the formation of laminar-structured GGO patterns. | |

| The resulting reduced graphene oxide (RGO) after chemical reduction showed remarkable electrical conductivity in printed graphene electronics (up to 4.51 × 104 S/m – which is among the highest reported in printed graphene electronics). | |

| The researchers attribute the high conductivity to the introduction of GGO as the printing ink, as well as the ordered structure from the process of assembly. | |

| Song points out that the size effect is also important for the enhancement of the conductivity. "A greater aspect ratio of the building blocks and their better alignment can give rise to a higher electrical conductivity of the printed patterns due to the closer stacking and lower intersheet contact resistance." | |

| Direct-write printing assembly of GGO could be particularly attractive for the application in soft actuators, where higher electrical conductivity contributes the better sensitivity of the devices; consequently it enables actuation with lower driving voltage. | |

| Because of their high conductivity, mechanical flexibility, and advantage in pattern design, printed graphene circuits/electrodes are promising for applications in electronic and optoelectronic devices; sensors and actuators; energy storage and electrochemical devices; and biological applications. | |

| "Large-sized graphene sheets as building blocks exhibit outstanding behavior in vacuum-filtered graphene films and wet-spun graphene fibers, but rarely are they adopted in the printing process," notes Song. "Inspired by the high performance results from macroscopic assembled graphene, we anticipate the properties of printed graphene can be tremendously enhanced by combined this material with versatile assembling strategies." | |

| The team also demonstrated the use of their flexible graphene electrodes toward the application in electrodriven actuators. The actuators could perform controllable shape change under electric signals. | |

| "By tailoring the ink composition and printing parameters, we could easily control the width and thickness of the electrodes," says Song. "That allowed us to fabricate the actuators with arbitrary geometries, enabling them to achieve complex deformations for application in soft actuators, bionic robots, artificial muscles, smart sensors, etc." | |

| Going forward, the scientists are planning to investigate the assembly of various forms and the resulting functionality of the printed graphene based materials. Direct ink writing is a versatile printing strategy to build up structures of both planar and three-dimensional shapes, as well to construct patterns for micro devices and large-area applications. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|