| Posted: Apr 19, 2006 | |

Bonding of carbon nanotubes to metal electrodes through ultrasonic nanowelding |

|

| (Nanowerk Spotlight) Building reliable interconnections between carbon nanotubes (CNTs) and external electrical and mechanical systems is an essential prerequisite to exploring the potential of CNTs in various domains. The formation of a stable and low-resistance ohmic contact between CNTs and electrodes contributes to speeding up the development of applications with CNTs in nanoelectronic devices with small size, fast speed and low power dissipation. | |

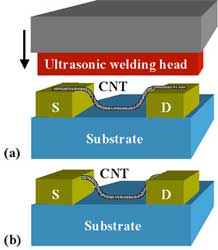

| In a recent paper, titled "Ultrasonic nanowelding of carbon nanotubes to metal electrodes" in Nanotechnology, first-authored by Changxin Chen, researchers at the Institute of Micro and Nano Science and Technology at Shanghai Jiao Tong University report a simple ultrasonic nanowelding technique to reliably bond single-wall carbon nanotubes (SWCNTs) onto metal electrodes, by pressing SWCNTs against electrodes under a vibrating force at ultrasonic frequency. | |

|

So far, many other methods have been attempted to connect CNTs with electrodes and improve their contacts, such as chemical bonding, focused beam radiation or high-temperature annealing. However, all of these applications are faced with difficulties: they either need rigorous process conditions or the contacts lack long-term stability. "We successfully developed a simple ultrasonic nanowelding technique for quickly and reliably bonding CNTs to metal electrodes by pressing SWCNTs against electrodes with a force vibrating at ultrasonic frequency " Chen explains to Nanowerk. "The contacts formed by this method have demonstrated low contact resistance, good long-term stability and mechanical strength. This ultrasonic nanowelding technique is compatible with traditional silicon IC processes." |

| Schematics of the ultrasonic nanowelding process. (a) before welding ; (b) after welding. (Source: Shanghai Jiao Tong University) | |

| The method developed by the researchers at Shanghai Jiao Tong University provides a simpler, less capital intensive and more scalable method to create reliable low-ohmic contacts between nano-components and electrodes, and thereby is readily applicable to industrial application. | |

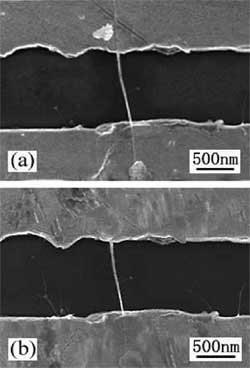

"This technique does not depend on a specific kind of nanocomponent or metal electrode" says Chen. "We find that ultrasonic nanowelding can also achieve the robust low-resistance contacts between the metal electrodes (Ti, Au, Al) and the Si nanowire, SiC nanowire, Ga2O3 nanobelt. Therefore, our technique is feasible for a wide range of one-dimension nanomaterials and metals." The performance of the devices prepared by this technique is also significantly improved. Chen and his colleagues have confirmed that the performance of CNT field-effect transistors (CNTFETs) can be greatly improved by the ultrasonic nanowelding technique. "Recently, we performed experiments of temperature dependence of two-terminal transport to further explore the contact properties of the semiconducting SWCNT and metal electrode" Chen explains. "Preliminary results indicate that a very low effective barrier height and a small barrier width is obtained after ultrasonic nanowelding. Our technique is very promising for the construction of other nano-devices and possesses the potential for a great many applications." At present, Chen and his colleagues are working to scale up the ultrasonic welding area in order to achieve a large quantity of bondings on a substrate in one single step, under one single press vibrating at a specific ultrasonic frequency. |

|

| SEM images of an individual SWCNT bridging the Ti electrodes before (a) and after (b) the ultrasonic nanowelding, respectively. (Source: Shanghai Jiao Tong University) | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.