| Posted: Nov 22, 2017 | |

Monitor your UV exposure with an adhesive nanoplasmonic patch |

|

| (Nanowerk Spotlight) Moderate exposure to sunlight has significant health benefits – vitamin D production, beneficial modulation of blood pressure, and psychological effects of well-being. However, exposure to ultraviolet (UV) radiation also is a major risk factor for most skin cancers. | |

| That means that, while moderate exposure to sunlight is recommended, there is a fine line to walk between beneficial and harmful amounts of UV exposure. | |

| To take the guesswork out of assessing the exposure to damaging UV rays, several wearable consumer UV sensors have already hit the market. For instance, we have previously reported on a stick-on epidermal electronics tattoo to measure UV exposure in a previous Nanowerk Spotlight. | |

| Researchers in Mexico have now proposed a simple and low-cost stick-on nanoplasmonic patch made of optically active silver nanoparticles (AgNPs) embedded in a film of nanopaper. The patch changes color once it has been exposed to a certain amount of UV light. | |

| The findings have been reported in an accepted paper in Analytical Chemistry ("Wearable Nanoplasmonic Patch-Detecting Sun/UV Exposure"). | |

|

|

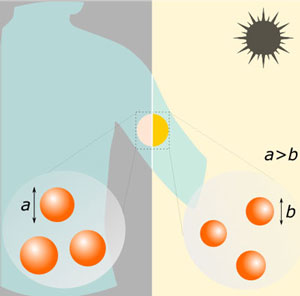

| Operational mechanism of the wearable nanoplasmonic patch. Before sun exposure (A), the patch embeds silver nanoparticles with an average diameter a. The original size of the particles embedded in the patch undergoes a modulation caused by a photolytic phenomenon upon Sun/UV radiation (B) resulting in a new average particle diameter b. This modulation of the nanoplasmonic properties of the patch is responsible for a change in color that is visually observable. (Reprinted with permission by American Chemical Society) | |

| "Before sun exposure, the patch embeds silver nanoparticles with an average diameter a," Dr. Eden Morales-Narváez, a research scientist in the Biophotonic Nanosensors Laboratory at the Centro de Investigaciones en Óptica A.C. in Mexico, tells Nanowerk. "The original size of the particles embedded in the patch undergoes a modulation caused by a photolytic phenomenon upon Sun/UV radiation, resulting in a new average particle diameter b. This modulation of the nanoplasmonic properties of the patch is responsible for a change in color that is visually observable." | |

| The main scaffold of this UV-responsive patch is made of bacterial cellulose nanopaper (average thickness of 16 µm), which is a flexible, lightweight, optically transparent and biocompatible material. | |

| Other approaches are based on polymer technology and require extra filters to be tuned according to the skin type of the user, which increases the complexity and cost of the resulting device. | |

| According to the team, their entire device is manufactured following a simple and green route, scalable, and costs about 0.05 USD for each patch (at laboratory scale). Also, it can be tuned – in terms of nanoparticle density – according to the skin type of the user without the need for extra filters. | |

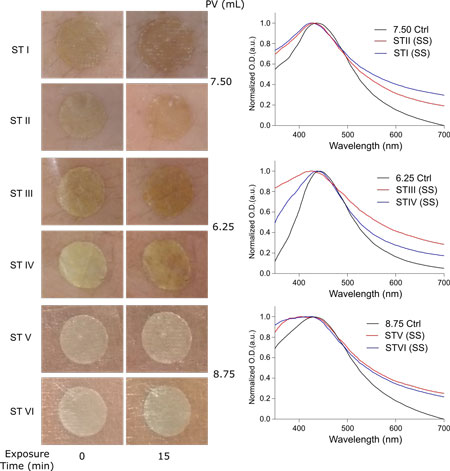

| The World Health Organization classifies skin types into six groups (I-VI) ranging from pale or freckled skin (type I) to naturally brown and black (types V and VI). The levels of sun/UV exposure that these groups can bear in a safe way varies significantly. Accordingly, a meaningful UV sensor needs to be tuned to take these differences into account. | |

|

|

| Epidermal studies of the wearable nanoplasmonic patch. The synthesis of the displayed nanoplasmonic patches was executed throughout 20 min. ST, skin type; PV, precursor volume. (Reprinted with permission by American Chemical Society) | |

| The operating principle of this nanoplasmonic patch is based on the phenomenon that silver nanoparticles change size upon exposure to UV light. To make sure that this effect happens within minutes and not hours, the team ran numerous experiments with a solar simulator in order to find the AgNp-decorated nanopaper with the fastest reaction time. | |

| "Importantly, as we have previously demonstrated, due to the nanostructure of bacterial cellulose, the spatial distribution of nanoparticles deposited within nanopaper is completely different when compared with the disposition of nanoparticles embedded within other conventional paper substrates such as nitro/cellulose," Morales-Narváez notes. "Moreover, it is worth mentioning that nanopaper and its optical transparency facilitates that the plasmonic properties of the embedded nanoparticles can be virtually completely exposed." | |

| He cautions that commercialization of this device is not going to happen quickly as the team needs to do more testing, find investors, and deal with regulatory requirements. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|