| Posted: Feb 12, 2018 | |

Nanocoating wiggles surface clean |

|

| (Nanowerk Spotlight) Soft robotics is a rapidly growing field in the robotics community that draws inspiration from the way in which living organisms move and adapt to their surroundings. It combines novel design concepts and fabrication approaches with soft, compliant materials (such as silicone and elastomers) to fabricate robotic devices. Soft robots are not necessarily made exclusively out of soft materials – but some or all of the mechanics are not primarily rigid. | |

| The soft materials used for this type of robots can perform work, change shape and execute functions driven by a variety of triggers – for instance light, electricity, or changes in their environment (humidity, presence of certain gases, etc.). | |

| Contributing to this field, researchers have developed a nanocoating that wipes off dust and sand from a surface by an electrical trigger, e.g. to clean solar panels in desert like conditions. Further applications could be removal of water droplets on car screens; dust removal from lenses and other optical systems; and controlling friction at or between surfaces. | |

| "Our novel coating forms dynamic surface undulations fuelled by an alternating electric field," Dirk J. Broer, a Professor at Eindhoven University of Technology, and head of the Laboratory for Functional Organic Materials & Devices, explains to Nanowerk. "This new approach is based on resonance enhanced microscopic (di)electric coupling of polar mesogens to the electric field." | |

| The particle-rejecting coating is made by in situ photopolymerization of a mixture of chiral reactive mesogens that forms a crosslinked chiral-nematic liquid crystal network on top of interdigitated electrodes. | |

|

|

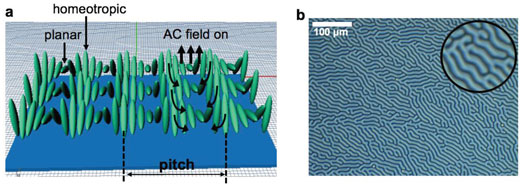

| Activation principle and the design of the electric driven surface topographies. a) Schematic representation of the molecular order and deformation of fingerprint LCNs coating. b) A typical fingerprint texture observed under the polarized optical microscope. (Reprinted with permission by Wiley-VCH Verlag) | |

| The team's expertise lies in making solid coatings based on liquid crystal networks (in a previous Nanowerk Spotlight we have reported on the group's work on on-demand liquid release from a sponge-like coating). The molecules in these networks are well organized in helices. By exerting a continuous force on these molecules at high frequency, the order of the molecules changes and a small non-occupied volume is generated in the form of sub-nanometer-sized dynamic voids. The change of the molecular order is the origin of the topographical inversion. The small dynamic voids initiate a high frequency oscillation at the surface. | |

| "With an eye on soft robotics, we wanted to make surfaces interactive, comparable with the human skin. They should be able to sense and, in response, act," he adds. | |

| Broer and his team have reported their findings in Advanced Materials ("Oscillating Chiral-Nematic Fingerprints Wipe Away Dust"). | |

| In this work, the researchers bring the surface of an organic coating into a continuous motion. The structure of the film has a fingerprint configuration with hills and valleys on the order of about 100 nanometers high and a few micrometers of separations. When powered by buried interdigitated electrodes the topography of the surface inverts: the hills become valleys and the valleys become hills. On top of this there is a continuous nanometer oscillation. | |

| When objects are on top of this surface they are brought into motion as well. As described in the paper, the team utilizes this to remove sand, both dry and wet, and dust, helped by gravity when the surface is slanted. | |

| "The initial application we have in mind is to remove sand/dust from solar panels in rural areas, desert solar farms or light-powered vehicles for space exploration such as the Mars Rover," says Broer. "Another application we foresee is touchpads of tablet computers that provide feedback to your fingers leading to a back- and forth information exchange." | |

| Besides scaling up to larger surfaces, the researchers already work on controlling the motion figures of deformation. For instance creating waves of deformation on the surface to transport material in the absence of gravity. | |

| "Implementation in real applications, such as a desert solar panel, will need more robust materials capable to resist continuous sun light and abrasive forces of sand storms," cautions Broer. "This has our attention and we are trying to solve this by changing the molecular structures becoming less sensitive for UV light degradation and by the application of deformable, abrasion resistive and UV absorbing top coats." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|