| Posted: Feb 14, 2018 | |

Wood nanotechnology for selective oil/water separation |

|

| (Nanowerk Spotlight) Aerogels, sometimes called frozen smoke, are nanoscale foams: solid materials whose sponge-like structure is riddled by pores as small as nanometers across. They can be made from different materials, for instance silicon. | |

| Aerogels are among the lightest solid substances in the world yet flexible, extremely strong and water repellent, which makes them very interesting materials for engineers. | |

| Cellulose aerogels, made from nanofibrils found in plants, have several unique features, one of which is super high oil absorption capacity that is several times higher than commercial sorbents available in the market. | |

| "Encouraged by our previous work on transparent wood ("Transparent wood for functional and structural applications"; "Optically Transparent Wood from a Nanoporous Cellulosic Template: Combining Functional and Structural Performance"; "Nanostructured Wood Hybrids for Fire-Retardancy Prepared by Clay Impregnation into the Cell Wall"), we started to develop porous wood/epoxy biocomposite materials that preserve the original hierarchical and porous structure of wood," Qi Zhou, an associate professor in the Department of Chemistry at KTH Royal Institute of Technology, tells Nanowerk. | |

| Reporting their findings in ACS Nano ("Wood Nanotechnology for Strong, Mesoporous, and Hydrophobic Biocomposites for Selective Separation of Oil/Water Mixtures"), Zhou and his KTH colleagues have created wood-based structures for oil/water separation, utilizing the native features of wood, i.e. its tubular porosity and hierarchical organization. | |

|

|

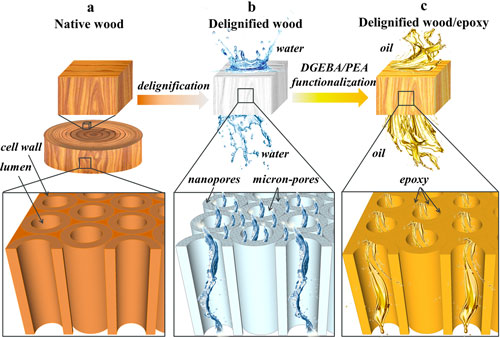

| Schematic illustration of structural design of porous and functional wood materials for selective separation of oil-water mixtures: (a) native balsa wood, (b) delignified wood template, (c) delignified wood/epoxy biocomposite. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The novelty here is the development of new processing routes for hierarchical wood structures scaled from nano-, to micro- and macroscales. | |

| In order to realize the vision of large-scale applications, wood nanotechnology and materials science need to combine in scalable processing technologies for industrial implementation. The development of delignified wood templates opens up the opportunity of future wood-based functional composite materials. | |

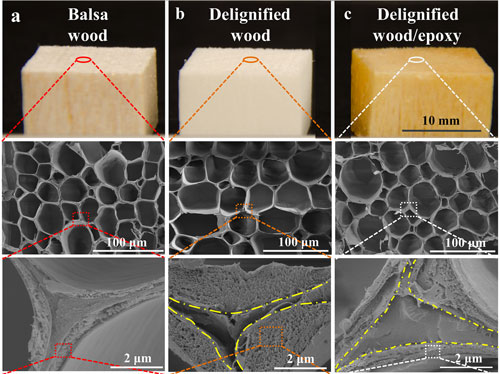

| The team's porous wood/epoxy biocomposite shows an oil absorption capacity of 15 grams per gram similar to aerogels and foams based on cellulose, but with 20 times higher mechanical properties (compression yield strength and modulus). | |

| "Our strategy is different from traditional wood modification methods," explains Zhou. "It involves two steps, a simple chemical treatment to first remove the lignin (delignification), then back infiltration of the wood cell wall with epoxy, leaving the lumen (a void space) open. In traditional wood polymer composites, both the cell wall and cell lumen are filled with polymer." | |

|

|

| Hierarchical structure demonstrated by photographs of the wood samples (10 ? 15 ? 15 mm3) and cross-sectional field emission scanning electron microscopy (FE-SEM) images of the cell walls for (a) balsa wood, (b) delignified wood template, and (c) delignified wood/ epoxy biocomposite. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The team used this template of a mesoporous delignified wood nanostructure, with nanoscale pores and micron-scale lumen channels, to prepare a functional wood/epoxy biocomposite with hydrophobicity and enhanced oleophilicity. This wood structure shows a high water/oil absorption capacity that allows for applications in oil/water separation. It can selectively absorb oil not only under water but also from the water surface. | |

| "We also anticipate that composite materials can be produced by coupling material engineering with chemistry for the processing of hierarchical structures," notes Zhou. "Functionalities can be further tailored by chemical modification thus providing anticipated properties that allow applications in structural materials, photonics, sensors, and optical devices." | |

| Prof. Lars Berglund, senior author of the paper, concludes that, going forward, the following two research questions are essential in this area: "Can the nanocellulose structure in wood and wood fibers be exploited so that nanocomposites with extended property range can be processed by industrial routes? Can the structure performance of wood be combined with new functionalities?" | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|