| Posted: Mar 19, 2018 | |

Customized design of multiple anti-counterfeiting marks with nanoimprinting |

|

| (Nanowerk Spotlight) Many animals such as bird, fish, butterflies and peacocks, get their beautiful colors not only from pigments, but also from nanoscale structures that manipulate light. Indeed, this so-called 'structural color' – where the color results from interferences, not pigments – is ubiquitous in nature. | |

| This success of nature's design has inspired researchers to develop numerous methods for incorporating structural color, i.e. the use of surface architecture without using chemical dyes and without altering the chemical composition of a material. | |

| Photonic crystals are optical materials for controlling and manipulating the flow of light. The structural colors they generate represent an attractive method for creating reflective displays since they can achieve a continuous color response and do not require back lighting. Other potential applications of these materials are in optical computing, the manufacturing of more efficient lasers, and a variety of optical applications, such sensors and diffraction gratings. | |

| "Reported approaches for structure coloration device fabrication, such as etching of porous anodic aluminum oxide (AAO), magnetically induced self-assembly, plasmonic scattering, negative-tone hydrogen silsequioxane and electron beam lithography, are either time-consuming and/or require expensive equipment and materials," Gou-Jen Wang, a professor in the Department of Mechanical Engineering, and Dean of the College of Engineering at National Chung Hsing University in Taiwan, tells Nanowerk. | |

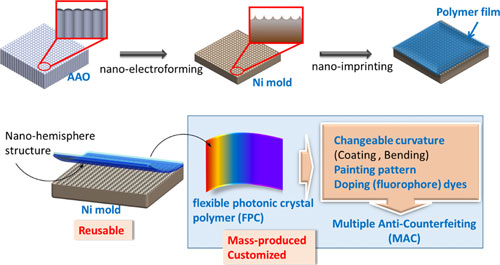

| Wang and his group have reported a simple method to facilitate the mass production of flexible photonic crystals (FPCs) with full-color grating properties (ACS Applied Materials & Interfaces, "Flexible Photonic Crystal Material for Multiple Anti counterfeiting Applications"). The nanoimprinted FPC structure is capable of displaying full-color grating properties because of the nano-hemispherical structures on its surface. | |

|

|

| Schematic of flexible photonic crystal (FPC) fabrication procedure. The Ni mold is reusable and consequently, the as-produced FPC can be customized and mass-produced for multiple anti counterfeiting applications. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

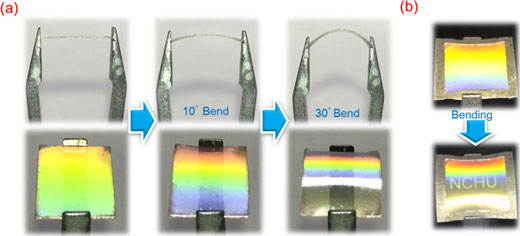

| This novel approach requires relatively inexpensive equipment and much less time than previous techniques. In addition, multiple anti counterfeiting applications can be easily implemented based on the polymer's intrinsic characteristics: surface curvature varies when the polymer film is bent or is coated with transparent substances of different surface tensions; the polymer film can be doped with (fluorophore) dyes or be patterned before nanoimprinting. | |

| In essence, this technique is a low cost and convenient nano-imprinting approach for mass production of customized multiple anti-counterfeiting polymer films. | |

| "Our FPC polymers are nanoimprinted on a nearly-transparent thin film, molded as visible water-chromogenic, deformed-chromogenic and photo-chromogenic out of the re-used nano-imprinting template," comments Wang. "Thus watermark, deformation, UV-excited multiple anti-counterfeiting functions can be achieved in a film at the same time." | |

|

|

| Effect of geometrical deformation on structural color change of printed polymer membranes. (a) Relationship between the structural color change and the curvature of the membrane, (top row) side view, (bottom row) top view; (b) additional anti counterfeiting feature of printed polymer membranes, (top) unbent membrane, (bottom) 20° bending membrane. (Reprinted with permission by American Chemical Society) | |

| Wang's team will continue this work with the goal of fabricating large area FPC structures in excess of 10 cm2. However, as the team cautions, the preparation of a large area Ni mold is a considerable challenge. | |

| "Our experimental results demonstrate that by using a nickel mold, it is possible to use nanoimprinting to produce FPC polymers with a full-color grating property," concludes Wang. "The unique chromogenic principles of the nanoimprinted polymer surface are very difficult to duplicate using existing techniques and have the advantages of being achieved with a low cost and can be mass-produced with customization." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|