| Posted: May 17, 2006 | |

New insights into the nanostructures and mechanical properties of single nanofibers |

|

| (Nanowerk Spotlight) In a rapidly growing field, electrospun biodegradable polymeric nanofibers are being used in scaffolds for engineering various tissues such as nerves, cartilages or bone. Recent research by scientists in Singapore offers new insights into the nanostructures and mechanical properties of single nanofibers. | |

| Electrospinning is widely used because it is a simple and cost effective method of producing nanofibers. When using such fibers as scaffolds for tissue engineering, it is important to know if these individual nanofibers are stiff and strong enough to withstand the forces exerted by the cells as they grow and migrate on the scaffold. The challenge has been isolating and handling individual nanofibers and not many tests have been done to characterize single nanofibers. | |

| In a recent paper, titled "Effects of annealing on the structural and mechanical properties of electrospun polymeric nanofibers", published in the May 28, 2006 issue of Nanotechnology, Professor Chwee Teck Lim and first author Eunice P S Tan from the National University of Singapore (NUS) studied the material properties of as-spun and annealed nanofibers. | |

| "We aimed to mechanically characterize a single nanofiber using both the tensile test and nanoscale three-point bend test. As some scaffolds may be heat-treated by annealing to enhance the stiffness and strength of the nanofibers, we also investigated the effects of annealing on the structural and mechanical properties of single nanofibers" Professor Lim explained to Nanowerk. | |

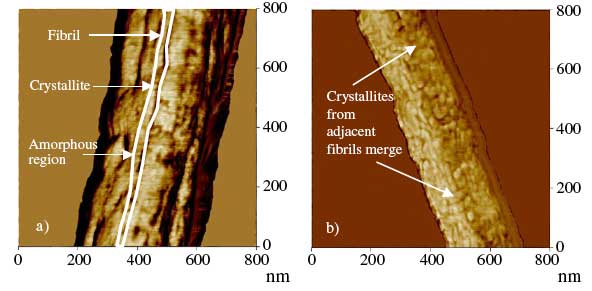

| "Annealing was found to increase the Young’s modulus of the nanofiber mainly due to the increase in crystallinity and the change in morphology from a purely fibrillar structure to a mixture of fibrillar and nano-granular structure with enhanced interfibrillar bonding. | |

| In previous work, Tan and Lim have already performed tensile test, three-point bend test and nanoindentation in order to characterize a single polymeric nanofiber. Because some scaffolds may be heat-treated by annealing to enhance the stiffness and strength of the nanofibers, in this study, the effect of annealing on the structural and mechanical properties of polymeric nanofibers is investigated. | |

| |

| Phase image of electrospun PLLA nanofibre. (a) As-spun nanofibre and (b) annealed nanofibre. (Reprinted with permission from the Institute of Physics) | |

| The Young’s modulus obtained from both techniques is in good agreement with each other. Visualization of the nanostructure of polymeric nanofibres has also been done using the phase imaging technique of the AFM. | |

| "This enables us to deduce how nanofibres deform and the stiffening mechanism that annealing induces for polymeric nanofibres based on the nanostructure observed" says Lim. "The effects of annealing on the Young’s modulus of a single nanofiber have also been reported for the first time." | |

| The method of observing the effect of heat treatment on the same nanofiber can be easily applied to other nanomaterials which may require heat treatment before being put into service. By monitoring the same nanofiber before and after heat treatment, the effects of heat treatment can be studied more accurately. | |

| With regard to future work, Lim expects researchers to develop in-situ methods of observing the change in the nanostructures of the single polymeric nanofibers during stretching and to develop methods of measuring viscoelastic properties of single polymeric nanofibers. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.