| Feb 19, 2019 | |

Smart droplets clean and repair surfaces |

|

| (Nanowerk Spotlight) Biological systems such as our immune system routinely carry out complicated tasks of recognition, transport and healing at molecular and cellular levels; yet researchers have found it challenging to extend such concepts to materials systems. | |

| Nevertheless, nature's elegant processes and designs have inspired numerous scientists to develop theoretical and experimental approaches to materials assembly and autonomous processes. | |

| For instance, in a previous Nanowerk Spotlight ("Repair nanobots on damage patrol (w/video)") we reported on engineered synthetic nanomotors that self-propel and autonomously detect surface cracks in electronic devices and rapidly restore the conductive pathway. These nanomotors were inspired by the chemotaxis of neutrophils toward inflammation sites and the aggregation of platelets at the collagen fibers of a wound to stop bleeding. | |

| One of the latest advances in the area of fluid-driven nanoparticle transportation, reported in Advanced Functional Materials ("Simultaneous 'Clean-and-Repair' of Surfaces Using Smart Droplets"), is a system in which debris resting on a substrate is relocated, in one step, from undamaged to damaged regions of the substrate, using functional droplets that recognize and transport the nanoparticles. | |

| Here, researchers used oil-in-water droplets stabilized by functional polymer surfactants as smart droplets that were able to recognize, pick up, transport, and drop off the nanoparticles, all in one flow system design. | |

| This simultaneous clean-and-repair approach reveals a novel self-healing system that conserves matter, behaves autonomously, and is implemented easily. | |

|

|

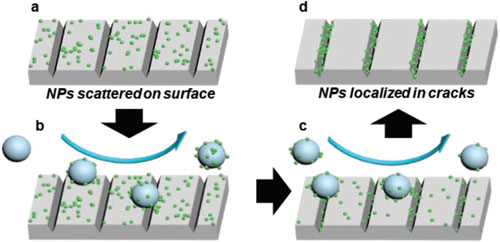

| Schematic illustration of the simultaneous clean-and-repair concept: a) Nanoparticle debris, shown as green spheres, is scattered on a damaged substrate; b) oil-in-water droplets flow across the damaged substrate and pick up the nanoparticles; c,d) the nanoparticles are deposited into the damaged areas by repeated contact between the droplets and cracks. (Reprinted with permission by Wiley-VCH Verlag) | |

| "We can take a material that has debris all over it, and use droplets to selectively move that debris into the damaged (cracked) regions of the structure," Todd Emrick, a professor in the Department of Polymer Science and Engineering at the University of Massachusetts Amherst, explains to Nanowerk. "One can easily imagine translating this advance to situations where one could massively conserve the amount of material used in healing a damaged structure i.e., rather than applying a new coating on the entire material, instead simply patching the damaged parts with an autonomous, smart fluidic system." | |

| He lists the key requirements necessary to successfully implement this design: | |

|

|

|

|

|

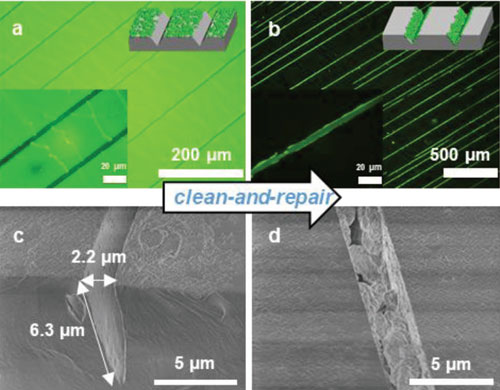

| a) Fluorescence microscope image of nanoparticle-coated substrate before clean-and-repair experiment; b) the same substrate after clean-and-repair; c) representative SEM image of a cracked portion of the substrate before clean-and-repair; d) representative SEM image of a cracked substrate area after clean-and-repair. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| This simultaneous clean-and-repair process has the potential to enable the restoration in many types of structural materials – from automotive coatings to microfluidic devices to bio-implants – with minimal external input, using only surfactant-stabilized droplets under flow. Ideally, this could lead to the development of a detection and repair system that would deploy so rapidly that repair would begin before damage becomes severe. | |

| Emrick and his team will pursue numerous lines of investigations, including whether the deposition of reagents to damaged regions of materials can do more than simply recover mechanical properties, but could also provide additional functionality (i.e., make a material better than it was before with new electronic or sensing functions). | |

| "We're motivated and challenged by theoretical advances associated with interfacial interactions of disparate materials, such as droplets, polymers, nanoparticles, etc.," he notes. "Our collaborator Anna Balazs at the University of Pittsburgh has made several key advances along these lines, which then challenge us to replicate her theories with experiments." | |

| "There is a long list of future challenges, including how to best integrate our findings with practical systems in a non-laboratory environment," he concludes. "But these challenges are not insurmountable and we have several routes in mind towards implementing our findings." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|