| Feb 18, 2020 | |

Color mixing for nanoplasmonic painters |

|

| (Nanowerk Spotlight) Conventional pigments produce colors by selectively absorbing light of different wavelengths. Red ink, for example, appears red because it absorbs strongly in the blue and green spectral regions. | |

| The reliance on dyes and chemicals for colorants is fraught with problems such as the fading of dyes due to chemical reactions; the need for different dyes for different colors; and the effect of dye-related chemical waste on the environment. | |

| Colors arising from plasmonic nanostructures – so-called structural colors – circumvent these issues. This mechanism of color generation takes advantage of the intense scattering of light by nanoscopic metal particles that are smaller than the wavelength of light. | |

| As a result of a resonant interaction of the illuminating light and the electrons in the particles – the so-called localized surface plasmon resonance – these nanoparticles generate distinct intense colors. Coloring with plasmonic nanostructures is typically more resistant to color fading and allows the realization of color images with much higher resolution than conventional color printing methods. | |

| Unlike color pigments, which can be overlaid to generate new secondary colors, discrete metal nanostructures rely on size, shape and relative positioning to generate new colors. | |

| Researchers already have developed techniques to achieve photorealistic plasmonic printing with nanostructures. Although these approaches extend the nanoplasmonic color palette, they introduce spatial non-uniformities and are limited to specific mixing ratios, which limits the total number of colors that can be represented. | |

| So far, though, it has not been possible to mix different colors in a single pixel, which is necessary to create fine transitions in color hues and tones and approach the broad palette available with well-established color systems. | |

| In new work published in ACS Nano ("A Plasmonic Painter’s Method of Color Mixing for a Continuous Red-Green-Blue Palette"), researchers at ETH Zurich have demonstrated a plasmonic color pixel and color-mixing approach with a high level of control over color luminance and chromaticity. | |

|

|

| Design and performance of the plasmonic red-green-blue (RGB) color primaries. (a) Schematic of the single color plasmonic pixel consisting of a lattice of silver nanorods on a glass substrate. White light illumination polarized along the long axis of the nanorods results in distinct colors observed in reflection. The length L and width W of the nanorods set the local surface plasmon resonance; the periodicity along the x direction, Px, sets the lattice coupling, and the periodicity along the y direction, Py, sets the color luminance. (b) Measured reflectance spectra of the red, green, and blue plasmonic primary colors. The nanorod lengths and widths are L = 143, 102, and 63 nm and W = 54, 54, and 57 nm for the red, green, and blue rods, respectively. The periodicities are Py = 330, 280, and 120 nm, respectively. (c) Optical bright-field image of the plasmonic color primaries in reflection. The dark background next to the color pixels is the residual reflection of the glass substrate. The scale bar is 10 µm, and the size of the pixel is 30 × 30 µm. (d) CIE chromaticity diagram with the location of the plasmonic color primaries under D65 standard illumination indicated by black stars. The white triangle represents the standard RGB (sRGB) color space, and the white circle represents the white color. (Reprinted with permission by American Chemical Society) | |

| What differentiates this work from previous studies is the ability to create very fine variations in colors and more accurate image representations with a continuous variation in color hues and brightness. | |

| "Similar to the way painters mix different hues and tones of colors on their palette, we demonstrated a method for continuous mixing of different colors at the nanoscale," Dr. Hadi Eghlidi tells Nanowerk. | |

| Eghlidi, who together with Prof. Dimos Poulikakos from the Laboratory of Thermodynamics in Emerging Technologies at ETH Zürich led this work, explains that this novel method for structurally generating and mixing vivid colors additively is based on interleaved rectangular lattices of metallic nanoparticles. | |

|

|

| A zoomed-in optical image of the printed Parrots (right) and the Scanning Electron Micrograph of the nanostructures (left) illustrates the approach in this work. (Image: Claudio Hail, ETH Zurich) | |

| "This coloring approach offers a large individual control over the chromaticity and luminance of the generated colors," he points out. | |

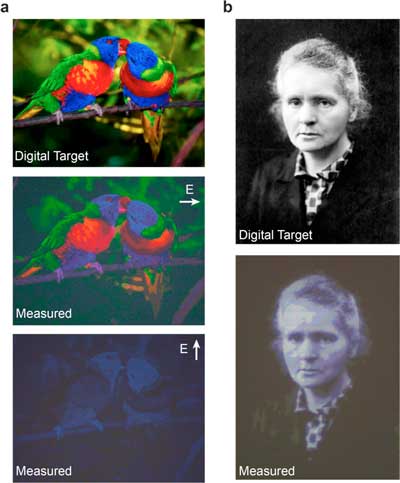

| "We demonstrate this by mixing the three colors red, green and blue, generated by three interwoven arrays of metal nanoparticles on a single pixel," adds Claudio Hail, the paper's first author. "We also illustrate how this can be used to create high quality images such as a photograph of a pair of colorful parrots with a pixel size as small as 1.28 µm x 1.28 µm." | |

| The researchers generated their colors by arranging silver nanoparticles in a rectangular array on a glass piece. The color hue is set by the size of the nanoparticles and their separation in the horizontal direction and the color brightness is varied by changing the vertical separation between the particles. The space in the array between the particles is utilized to interleave another array of a different color, allowing the smooth mixing of colors. | |

| As a result of their color mixing method, the team can create fine variations in color hues and brightness, which then allows to continuously span a color palette, as opposed to previous works where only distinct color hues were reproduced. As a result, this enables a more photorealistic representation of illustrations with high resolution at the nanoscale. | |

|

|

| Photorealistic color printing with plasmonic RGB (pRGB) coloring. (a) Digital image of two colorful parrots and its corresponding measured optical bright-field image generated using pRGB color mixing acquired with linearly polarized light along the nanorod long axis (middle) and along short axis (bottom). The image shows smooth transitions between the different color hues and tones as enabled by our color-mixing method. The fabricated image is 240 × 312 µm in size with pixels of 1.28 × 1.28 µm. (b) Digital grayscale portrait of Marie Sklodowska Curie and its measured optical bright-field image. The fabricated image is 318 × 233 µm in size with pixels of 1.28 × 1.28 µm. The nanorod lengths and widths in (a) and (b) are L = 143, 102, and 63 nm and W = 54, 54, and 57 nm for the red, green, and blue rods, respectively. (Reprinted with permission by American Chemical Society) | |

| "Although showing smooth transitions in color with very high resolution and within ultrathin layers, the vividness of the colors of our engineered surfaces is still less than what most modern displays are able to represent," Hail notes. "A next stage in our work will therefore be to find ways to further increase the vividness of the mixed colors in order to surpass the range of colors that can be currently displayed on most available displays." | |

| At a later stage, the team will try to find ways to dynamically mix colors together, meaning a color pixel that over time can independently change the content of red, green or blue in a pixel. | |

| Potential applications for this work could be new types of security tags, anti-counterfeiting, or transparent and high-resolution displays. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|