| Posted: Jun 08, 2006 | |

3-dimensional nanowire networks make for ultrasensitive and highly selective gas sensors |

|

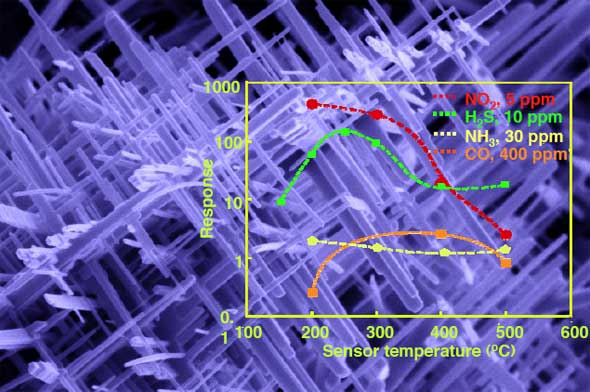

| (Nanowerk Spotlight) The sensitivity of solid-state gas sensors can be improved if the surface-to-volume ratio of the material used for the sensor is increased. An international group of researchers demonstrated that three-dimensional tungsten oxide nanowire networks can serve as a high-surface area material for building ultrasensitive and highly selective gas sensors. The results highlight that the 3-D nanowires technology can be adopted for the development of gas sensors with performances suitable for practical applications. | |

| Nanowires are uniquely suitable for sensor applications because of their single-crystalline structure, large surface-to-volume ratio, and high stability. Nanowire based sensors already have been demonstrated for detecting gases, proteins, single virus, and single cancer markers. Nanowires and nanobelts exhibit optimal structural characteristics for both high sensitivity and long-term stability. | |

| While research so far mainly focused on thin films and nanowires, Professor Zhong Lin Wang from the Georgia Institute of Technology, and researchers from the Università di Brescia in Italy, and Sun Yat-Sen University in PR China, used 3-dimensional networks of nanowires for gas sensors, so that the surface area and sensitivity improved drastically. Their findings were reported in a paper titled "Ultrasensitive and highly selective gas sensors using three-dimensional tungsten oxide nanowire networks" that was published in the May 15, 2006 online edition of Applied Physics Letters. | |

| "In comparison to thin films and nanowires, the 3D networks of nanowires largely improve the contact surface of the sensor with the gas" Wang points out. "More importantly, the multiple channels of current path greatly reduces the resistance of the structure, thus, the sensor sensitivity has been largely improved." | |

| Wang and his colleagues built the sensors by drop coating of WO3-x nanowire networks onto alumina substrates. The resulting sensors have been shown to be able to detect NO2 concentration to 50 ppb (parts per billion) level. That is comparable with what traditional thick and thin film technologies are capable of after 50 years of research. | |

| |

| SEM images of tungsten oxide nanowire network. Inset is the Sensor response to NO2, H2S, NH3, and CO as a function of working temperature. Relative humidity is 30% at the chamber temperature of 20°C. (Source: Zhong Lin Wang, Georgia Tech) | |

| The sensor based on this approach could be directly used for gas sensing and chemical sensing. It will make it possible to directly use nanomaterials for fabricating nanosensors and nanodevices. | |

| "The outdoor application, due to its low threshold limit of 50 ppb, is considered as the frontier also for thin and thick film technology typically adopted in the gas sensing field" says Wang. "The present results thus demonstrate that nanowire technology can be used to reach results at least comparable with the best ones obtained by the "traditional" technology." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.