| Aug 11, 2020 | |

Nanocoatings could prevent bird-strikes |

|

| (Nanowerk Spotlight) To birds, trees and sky reflected in glass appear to be habitat. They fly into windows at high speeds, and the loss of life is staggering. Between 360 million and 1 billion birds are killed by collisions with glass just in the United States alone every year. | |

| Bird vision is different from our human vision. Our eyes contain three types of color cone receptors that are sensitive to red, blue and green frequencies of light from wavelengths of roughly 400 nanometers (violet) to 700 nanometers (red). | |

| Birds, however, have a fourth receptor that varies across species in the type of frequency it can detect. Most birds have their fourth photoreceptor sensitive to wavelengths in the near ultraviolet range (300–400 nm). That means that, unlike humans, most birds can see UV light. | |

| "It stands to reason that applying UV-reflecting coatings or patterns on windows and glass buildings can be particularly advantageous to prevent bird strikes," Dr. Tania Dey from the College of Engineering at Swansea University, tells Nanowerk. | |

| Dey hypothesized that tuning the UV reflectance properties of window glass (or any other surface for that matter) could result in higher UV reflectance that could be noticed by birds and potentially reduce bird-strike incidences, particularly in high-rise buildings and airplanes. | |

| Nanoscale titanium dioxide (TiO2) is a widely used material in sunscreen products to make the UV-blocking ingredients. It is also being used in UV-shielding paint, ink, plastics and textiles, automotive metallic paint, and silicone rubber. | |

| Reporting her findings in Surface Engineering ("UV-reflecting sintered nano-TiO2 thin film on glass for anti-bird strike application"), Dey developed a sintered sol–gel derived transparent nanocrystalline TiO2 coating on glass that can significantly increase UV reflectance. | |

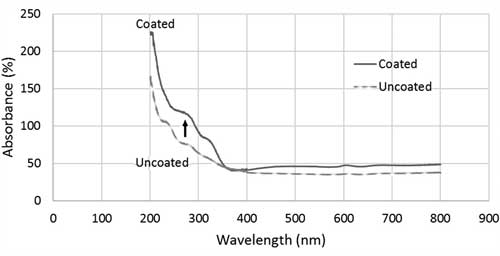

| As there is a relationship between the UV-ray shielding effect and particle size, it is essential to determine the optimum particle size for maximizing the UV-ray shielding effect. The particle size in the sol–gel derived nanocrystalline TiO2 coating developed by Dey is ∼148 nm. Deposited by layered dip-coating method and heat treated by in situ sintering, it is capable of increasing the UV reflectance of glass by 27.8%. | |

|

|

| UV-visible diffuse reflectance spectra as a function of wavelength for uncoated and sintered nano-TiO2 coated quartz glass. (Reprinted with permission by Taylor & Francis) | |

| "This glass coating can significantly affect bird’s vision and potentially reduce bird-strike incidences," Dey points out. "The aviation and construction industries could potentially benefit immensely from this research." | |

| Moreover, this type of coating can be deposited on various substrates, not just glass, and the inherent anti-microbial properties can be utilized, which can be particularly advantageous in the context of the current coronavirus epidemic. Dey already has embarked in one such project. | |

| "There is room to improve the nano-formulation further in terms of sol-gel recipe, sintering temperature, crystallinity and porosity, to achieve a higher increase in UV reflectance," Dey concludes. "The challenge, though, will be to develop a technique that allows cost-effective, rapid and large-scale coating of commercial window products." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|