| Oct 22, 2020 | |

Laser shockwave transforms bioinspired ultrahigh molecular weight polyethylene |

|

| (Nanowerk Spotlight) For many years now, the remarkable properties of some natural materials have motivated researchers to synthesize biomimetic nanocomposites that attempt to reproduce Nature’s achievements and to understand the toughening and deformation mechanisms of natural nanocomposite materials. | |

| One of the best examples is nacre, the pearly internal layer of many mollusc shells. It has evolved through millions of years to a level of optimization currently achieved in very few engineered composites. Think of seashells as natural armor materials. | |

| Being able to replicate the extraordinary mechanical properties of nacre and other biological structures could lead to synthetic materials that possess the exceptional mechanical properties required to perform under extreme conditions – jet engines, power turbines, catalytic heat exchangers, military armors, aircraft, spacecraft, just to name a few (read more in our previous Nanowerk Spotlight: "Replicating nacre through nanomimetics"). | |

| In this context, ultrahigh molecular weight polyethylene (UHMWPE) is a high-performance specialty polymer with a unique set of properties and applications. It shows remarkable strength-to-weight ratio and an excellent energy absorption ability, making it a promising material for protective applications such as body armor, biomedical implants or heat-resistant coatings. | |

| "The mechanical properties of UHMWPE are largely dictated by its nonhomogeneous microstructure and crystalline organization nature," Shenqiang Ren, a Professor in the Department of Mechanical and Aerospace Engineering, Chemistry and the RENEW institute at the University at Buffalo, tells Nanowerk. "In our work we are trying to solve the challenge of the crystallinity control and polymer chain alignment in UHMWPE, which play an important role in its energy absorption and thermal conductivity – both are important characteristics for the applications of UHMWPE." | |

| In new work reported in ACS Applied Materials & Interface ("Hierarchical Structural Engineering of Ultrahigh-Molecular-Weight Polyethylene"), Dr. Lu An describes how a non-equilibrium manufacturing process, together with ultrahigh-strain-rate laser shockwave peening, triggers high crystallinity and unusual phase transformation of three-dimensional UHMWPE. | |

| This work is the continuation of the team's earlier research (ACS Applied Polymer Materials, "Functional Gradient Ultrahigh Molecular Weight Polyethylene for Impact-Resistant Armor") where they demonstrated that the incorporation of nanoparticles enhances the mechanical properties of functionally graded UHMWPE. | |

| The pulsed laser shockwave treatment triggers a hardened surface layer with enhanced crystallinity. It also increases the mechanical strength of UHMWPE. | |

|

|

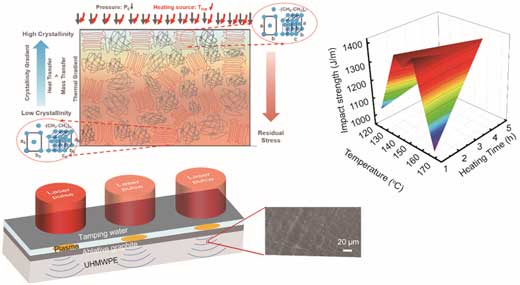

| Manufacturing and gradient crystallinity principle of nacre inspired UHMWPE. (a) Schematic illustration of modified compression mold of UHMWPE through directional solidification, and schematic of crystallinity gradient and residue compressive stress gradient in UHMWPE under high pressure and high temperature load. Adapted and reprinted with permission from American Chemical Society) (click on image to enlarge) | |

| To demonstrate the possibilities for these materials, the team took inspiration from the paws of animals. Some, especially felines and canines, can safely jump from great heights due to their paw pad structure as a multilayer cushion system to ground impact resistance. | |

| "The stratified epithelium layer in the paw pad is hardest hit by ground impact, and the intermediate dermis layer composed of honeycomb-like patterns with the embedded dermal papillae could effectively attenuate the ground impact, while the internal subcutaneous layer is used for energy absorption," Ren and An explain. "This biological design inspired our manufacturing process of lightweight, tough composite materials: We incorporated a vertical Kevlar® fiber array into the UHMWPE matrix for the formation of fiber reinforced polymer composites to mimic high impact performance paw pad structures." | |

| The result is a fiber-reinforced composite material that enables high surface hardness and superior impact resistance. The multiscale modeling was provided by Prof. Danial Faghihi at the University at Buffalo. | |

| "These bio-inspired structures shed light on the utility of advanced polymer materials for emerging lightweight structural applications," Ren concludes. "We are continuing to explore the mechanical, thermal conducting and electric insulation properties of UHMWPE and its composites, which are largely controlled by its crystallinity and polymer chain alignment. Going forward, we will address the remaining challenges of crystallinity and polymer chain alignment control of ultrahigh molecular weight polyethylene." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|