| Feb 23, 2021 | |

Using living bacteria to design self-growing engineering materials |

|

| (Nanowerk Spotlight) The structural materials that are currently used in our human-built environments wear out due to age and damage, and have limited ability to respond to changes in their immediate surroundings. In contrast, living biological materials like bone, skin, bark, and coral, have attributes that provide advantages over the non-living materials people build with – they can be grown where needed, self-repair when damaged, and respond to changes in their surroundings. | |

| Simply put: Biological systems in nature assemble living materials that are autonomously patterned, can self-repair and can sense and respond to their environment; however, engineering materials typically cannot (grown engineering materials are not entirely new, e.g. wood, but they are rendered inert during the manufacturing process, so they exhibit few of their components’ original biological advantages). | |

| The inclusion of living materials in human-built environments could offer significant benefits. Unfortunately, scientists and engineers are unable to easily control the size and shape of living materials in ways that would make them useful for construction. | |

| This has led to the emergence of a relatively new research field: Engineered Living Materials (ELMs). This is a novel class of materials that exploit the properties of living organisms. DARPA has even launched an Engineered Living Materials program seeking to "revolutionize military logistics and construction in remote, austere, high-risk, and/or post-disaster environments by developing living biomaterials that combine the structural properties of traditional building materials with attributes of living systems, including the ability to rapidly grow in situ, self-repair, and adapt to the environment." | |

| Ultimately, ELMs could lead to a future where diverse materials could be grown at home or in local production facilities, using biology rather than resource-intensive centralized manufacturing. | |

| Researchers at the University of Southern California have now reported progress in exploiting living bacteria and 3D-printed materials to grow bionic mineralized composites with ordered microstructures (Advanced Materials, "Growing Living Composites with Ordered Microstructures and Exceptional Mechanical Properties"). | |

| This paper provides an example of harnessing living bacteria to design self-growing materials and opens the door for a new class of engineering materials that can self-grow like living creatures. | |

| "We have developed a strategy to manufacture bionic mineralized composites by harnessing bacteria-assisted mineralization within 3D-printed polymer scaffolds," Qiming Wang, the Stephen Schrank Early Career Chair in Civil and Environmental Engineering and an assistant professor in the Department of Civil and Environmental Engineering at the University of Southern California, tells Nanowerk. "Compared to other existing methods, our bionic method can produce mineralized composites with high fractions of minerals and highly ordered mineral orientations." | |

|

|

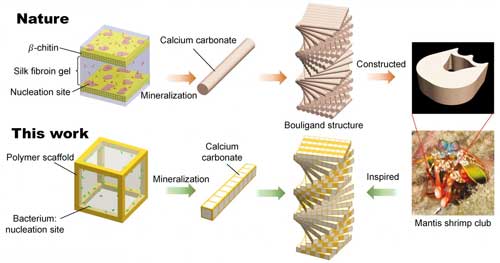

| Top: Schematics shows the production process of mineralized structural composites in living creatures (such as stomatopod dactyl club). Bottom: Schematics shows the proposed strategy for growing bionic composites in this work: bacteria-assisted mineral growth within a 3D-printed scaffold. (Image: Qiming Wang, USC Viterbi School of Engineering) (click on image to enlarge) | |

| Wang and his team's work focusses on mineralized composites. These are tough materials that widely exist in nature, such as teeth, pearl, nacre, and mantis shrimp club. To design mineralized composites with high fracture toughness, two requirements must be met: The mineral volume fraction should be high; and the mineral fibers should form microstructures with ordered orientations (such as the Bouligand structure). | |

| "Nature's growing method can fulfill both requirements," says Wang. "However, existing engineering methods can only fulfill one requirement: either a high volume-fraction of minerals, or a complex architecture of mineral layout." | |

| The team's new method can fulfill both requirements: the mineral volume fraction is relatively high (45-90%) and the mineral layout follows an ordered microstructure. | |

| "Although bacteria-assisted mineralization has been previously used to heal cementitious materials, harnessing guided bacterial mineralization to design structural composites has not been explored," Wang notes. | |

| This novel manufacturing strategy primarily relies on bacteria-assisted mineral growth within 3D-printed microporous lattice scaffolds. | |

|

|

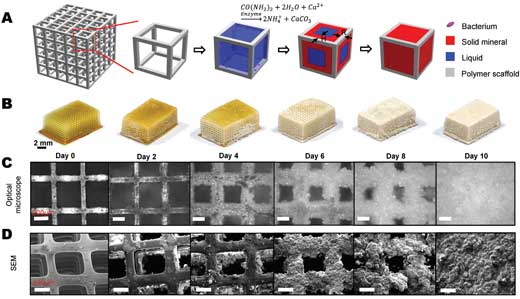

| Bacteria-assisted mineral growth within a 3D-printed lattice scaffold. A) Schematics to show the bacterial-assisted mineral growth process. H is the mineral thickness and R is the half beam width. B–D) Samples (B), their optical microscopic images (C), and their SEM images (D) during the bacteria-assisted mineral growth process over 10 days. (Reprinted with permission from Wiley-VCH Verlag) (click on image to enlarge) | |

| The researchers work with specific bacteria (S. pasteurii) known for secreting the enzyme urease. When urease is exposed to urea and calcium ions, it produces calcium carbonate, a fundamental and strong mineral compound found in bones and teeth. By guiding the bacteria to grow calcium carbonate minerals, the researchers achieved ordered microstructures, which are similar to those in the natural mineralized composites. | |

| "Because our new materials fulfill both requirements – a high volume-fraction of minerals as well as a complex mineral architecture – the mechanical property of our bionic materials are exceptional," Wang points out. "They exhibit outstanding specific strength and fracture toughness that are comparable to natural composites, and exceptional energy absorption capability that is superior to both natural and artificial counterparts." | |

| These materials could find applications in areas that require high-performance structures such as aerospace panels and vehicle frames. The materials are relatively lightweight, also offering options for defense applications like body or vehicle armors. | |

| "An interesting vision is that these living materials still possess self-growing properties," says Wang. "So for instance if we use them in a bridge, we can repair any damage by introducing bacteria to grow the affected structures back." | |

| This video shows the overall experimental procedure of the proposed method. | |

| The next stage of the team's research is to use living bacteria to grow additional functional materials that cannot be made by existing methods. | |

| "Our strategy highlights an exciting opportunity for future hybrid synthetic–living bionic materials by tailoring interactions or communications between living organisms and 3D-printed synthetic materials," Wang concludes. "The manufacturing strategy can be easily extended by selectively controlling the activity of living organisms to synthesize unprecedented structural composites with ordered, hierarchical, and gradient microstructures." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|