| Jun 02, 2021 | |

Nanophotonics and nanofabrication combine to achieve 3D color prints |

|

| (Nanowerk Spotlight) A new generation of lenses ('metalenses') is starting to replace bulky curved lenses with simple, flat surfaces that use nanostructures to focus light. These flat surfaces ('metasurfaces') enable the design of diffraction-based flat devices to replicate the functionalities of conventional lenses with sub-wavelength or few-wavelength thicknesses. | |

| These metasurface materials have led to the development of novel optical devices such as holograms, gratings, axicons, or polarization-selective devices, and might even put true holographic movies within grasp. | |

| Already, researchers are working on the development of full-color, three-dimensional (3D) displays – holograms – and matrix-free 3D displays for the naked eye are within reach (read more in our previous Nanowerk Spotlight: "Full-color 3D meta-holography with a single nanostructured layer"). | |

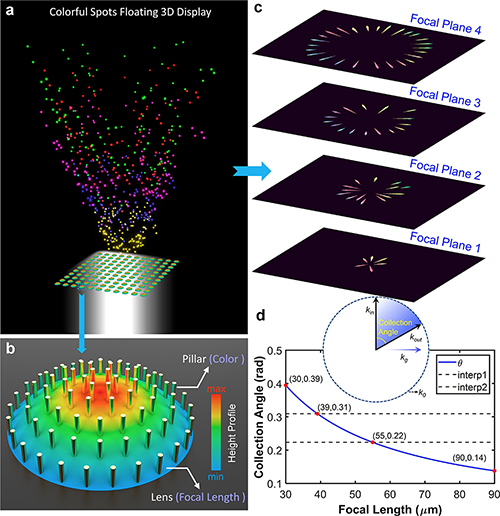

| With a new approach, that brings us closer to the commercial application of 3D color holograms, a team of scientists at Singapore University of Technology and Design (SUTD) have developed the concept of a virtual 3D color object consisting of colorful focal spots at discrete heights in the out-of-plane dimension above the surface of a print – something they dubbed 'optical fireworks'. | |

| "Unlike previous 3D color holograms, our color-filtering microlens-based displays realize multicolor and multifocal simultaneously in the form of bright colorful focal spots floating above the prints," Joel Yang, an Associate Professor at SUTD tells Nanowerk. "These spots appear at different distances along the optical axis and are imaged onto a charge-coupled device camera or observed under an optical microscope. These optical fireworks are quite different from 3D holograms as they are visible under incoherent white light illumination." | |

|

|

| Figure 1. (a) Illustration of 'optical fireworks' with colorful focal spots in free space from a CFML array and illuminated with collimated incoherent white light. (b) CFML consisting of a microlens combined with nanopillars. The profile of the microlens determines its focal length and position of the bright spot above the substrate. The color bar represents the height profile of microlenses. Nanopillars on the surface are structural color filters that modulate transmitted spectrum to generate colors. (c) Optical fireworks imaged at different focal planes representing different time steps. (d) Linear distributed collection angles of designed CFML in such manner the crosstalk between four focal planes is negligible. Inset: Collection angles of microlens in the spatial frequency domain (k-space). (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| Yang and his team report their findings in ACS Nano ("Optical Fireworks Based on Multifocal Three-Dimensional Color Prints"). | |

| "Our main idea is to combine nanopillars and microlenses to achieve color-filtering microlenses using a two-photon polymerization lithography 3D-printing technique," explains Hongtao Wang, the paper's first author. "By modifying the heights of the nanopillar we can control the colors of the focal spots; and through the height profiles of microlenses we can control the floating heights of colorful spots above the print. In this way, arbitrary colorful focal spots can be placed in 3D space to form an as-designed and recognizable 3D visual effect." | |

| In contrast to other 3D displays, the team's optical fireworks is based on color-filtering microlenses and therefore totally passive as it does not require a coherent laser source or external electric source. That makes it more suitable to be an optical security label because the inspection method is much easier. | |

| "The prints themselves appear plainly as a collection of colorful disks, each corresponding to a color-filtering microlens," says Wang. "However, as one continuously shifts the focal plane above the printed surface, the optical fireworks appear as an animated collection of multicolor bright spots that dynamically appear to light up and disappear with the changing focus of an optical microscope." | |

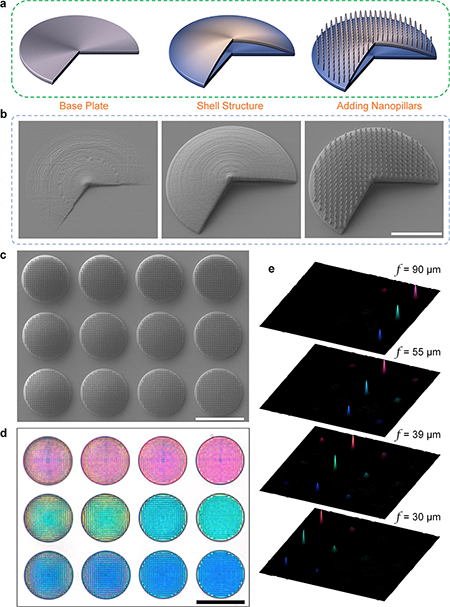

| To reduce print time and increase print quality, the researchers optimized the fabrication process and divided it into three steps, as illustrated in Figure 2 below. | |

|

|

| Figure 2. Fabrication process of the color-filtering microlens and corresponding optical properties. (a) 3D models of the three-step fabrication method of UV-cured shelled structures. A shelled structure is printed at first, and then the resist inside is solidified by UV-curing. (b) SEM images of base plate, shell structures, and color-filtering microlens. Scale bar: 10 µm. (c) SEM images of systematic color-filtering microlens array, with focal lengths varying from 30 µm, 39 µm, 55 µm to 90 µm (from left to right), while pillar heights changing from 1.0 µm, 1.5 µm to 2.1 µm (upward). Scale bar: 25 µm. (d) Corresponding images captured in transmission mode with an optical microscope; the focus of microscope is at the top surface of the color-filtering microlens. Both SEM and optical micrographs show little observable difference within each row of lenses. Scale bar: 25 µm. (e) Colorful focal spots at different focal planes. Colors of cones indicate the colors of focal spots, while the heights of cones represent intensities. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| This work provides a way of arranging metalenses into a much bigger surface, making it an attractive option for photonic anti-counterfeiting devices that work by controlling the colors of focal spots and their 'floating heights'. | |

| "In the future, optical nanodevices in complex 3D structures will find broad applications because they explore more dimensionalities and freedom of light, providing unique features, which hardly can be achieved by 2D structures," Yang concludes. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|