| Jun 27, 2022 | |

Spray-n-Sense: Spray-painting sensors on any surface |

|

| (Nanowerk Spotlight) Over the past few years, the development of materials that act as chemical paints (i.e. coatings) by responding to a (bio)chemical parameter with a change in their optical properties has developed into an exciting new field. In a typical application, the object of interest is painted and the color or fluorescence of the paint is monitored by methods of optical imaging. | |

| This technique represents a simple but exciting technology to monitor (bio)chemical and even physical parameters over relatively large or difficult to reach areas and in real-time without having to look at only a minute sample through a microscope. | |

| Increasingly incorporating nanostructures, over the years researchers have developed numerous portable and on-site sensing platforms such as colorimetric sensors, solid-state sensing tools, and paper-based microfluidic sensors. | |

| In new work reported in Advanced Functional Materials ("Spray-n-Sense: Sprayable Nanofibers for On-Site Chemical Sensing"), researchers in Australia have now demonstrated a sprayable on-site sensing tool. | |

| The main application area for this sensor spray is the detection of specific analytes in an environment where sample collection is a difficult task either due to the target chemicals themselves or the area where the samples are located. | |

| "Our Spray-n-Sense consists of chromogen-doped polymer that is sprayed out in the form of nanofibers using a simple nebulization method and a phone-based application," Dr Tushar Kumeria, Scientia Senior Lecturer & NHMRC Early Career Fellow in the School of Materials Science and Engineering at the University of New South Wales in Sydney, explains to Nanowerk. "The nebulization method allows for nanofibers to be sprayed onto any surface, while the accompanying phone-based application allows for direct on-site detection." | |

|

|

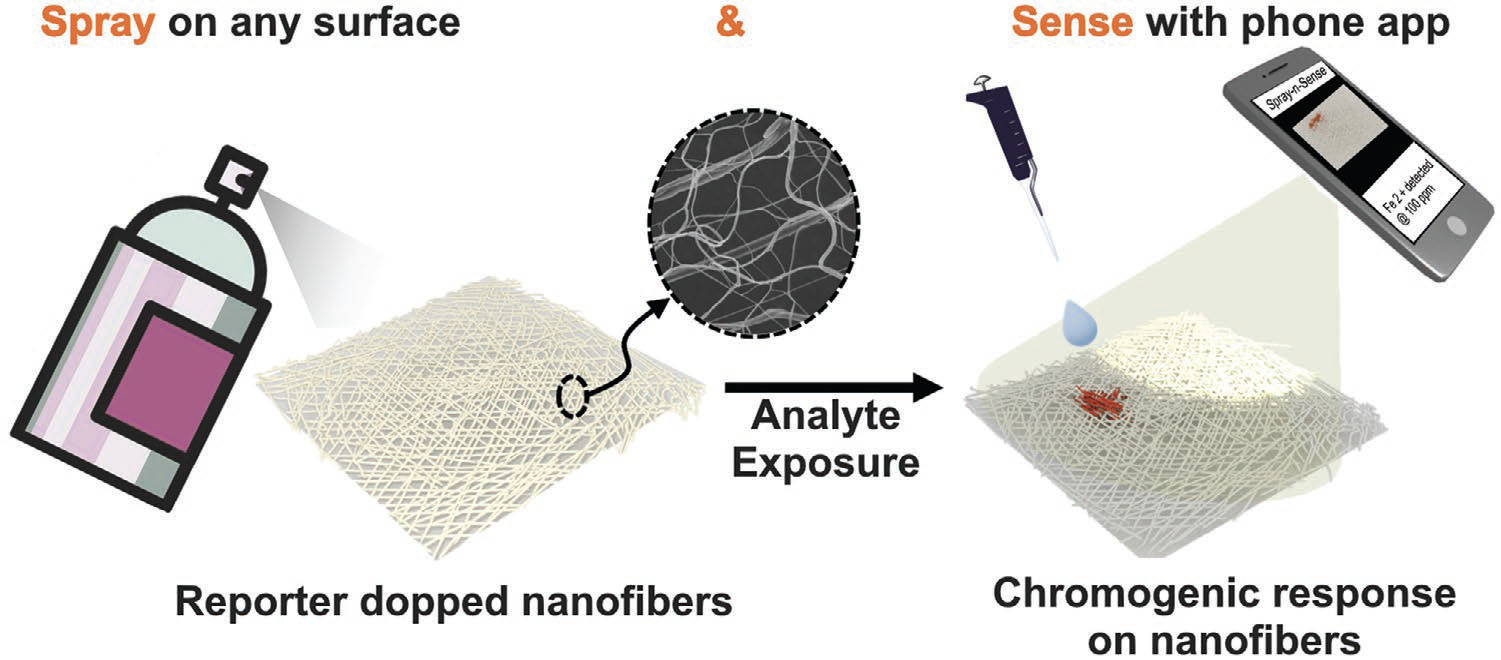

| Schematic illustration of the Spray-n-Sense nanofibers. Chromogenic reporter doped nanofibers are sprayed onto the surface that has the sample analyte or onto a surface. When analytes encounter the reporter doped nanofibers, the change in color reports the presence of the target analyte. Whereas the smartphone-based application can be used to quickly take a photograph and quantify the amount of analyte based on the intensity of the color. The nanofibers can be tuned to detect the target analyte by switching the chromogenic reporter selective towards the analyte of choice. (Reprinted with permission by Wiley-VCH Verlag) | |

| This has the potential to measure target chemicals at places where it is difficult to collect samples, e.g. a leak of a toxic chemical, or in a security scenario where these sensors could be sprayed using miniature drones and photos taken can be used to analyze the presence of potentially dangerous agents. | |

| "My research has always focused on the design and development of easy-to-use sensors that are portable and is driven by real-world challenges in detecting chemicals at ultra-low levels with high selectivity," says Kumeria. "For instance, nanofiber-based sensors have been demonstrated for colorimetric sensing before, but the nanofibers had to be prepared using electrospinning. However, with the electrospinning process the nanofibers can only be sprayed onto conducting surfaces and require very high voltage (>kV), which is not suitable for applications in the field. Whereas our sprayable nanofibers sensors only require compressed gas, making it possible to spray nanofibers even on non-conducting surfaces." | |

| To enable true on-site detection and quantification of analytes with the Spray-n-Sense nanofiber sensors, the researchers also designed and developed a compatible smartphone-based application. This Android-based app is designed for on-site calibration with a representative color scale that can be used to calibrate the phone camera to the illumination conditions on-site for an accurate analyte detection and quantification. | |

| The application performs on-site image analysis of the visually quantifiable color or fluorescence changes on the area of analyte exposure by calculating relative pixel intensity per ppm from photographs of the nanofibers exposed to the analyte. | |

| "Combining the sprayable nature of the nanofibers and the phone-based application, our system can perform true point-of-analysis sensing providing both qualitative (change in color or fluorescence) and quantitative (intensity of signal) information by capturing digital photos of exposed nanofibers," says Kumeria. | |

| He points out that the chromogenic dopants in the polymer matrix chosen for this work can be easily switched to make the sprayable sensors selective to different target analytes. For example, in this work, the same polymer backbone matrix was doped with three different dopants (chromogenic or fluorogenic) to the selectivity of the sensors towards target metal ions or ammonia. | |

| The team is further investigating more specific dopants with high sensitivity and selectivity towards a range of chemical and biological analytes. They are also working towards a more compact nebulization device that can be carried in a lunch-box-sized package. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|