| Sep 29, 2022 | |

Roll-to-roll fabrication of flexible printed perovskite solar cells under ambient conditions |

|

| (Nanowerk Spotlight) Lightweight and flexible perovskite solar cells are a new technology in which photovoltaic cells are manufactured using roll-to-roll printing and coating methods to deposit all the functional materials such as perovskites on flexible plastic substrates. The ability to print them simply like printing newspapers also offers significant cost benefits. | |

| Usually, the top electrode of a perovskite solar cell (PSC) is deposited using complex high vacuum-based metal evaporation techniques. Typically, this evaporated metal layer is either gold or silver and thus is the most expensive component of the device. | |

| A team of researchers from Australia’s national science agency CSIRO and Monash University has been able to successfully replace this expensive metal layer with a less-expensive carbon-based electrode that can also be applied using roll-to-roll techniques. They report their findings in Advanced Energy Materials ("Vacuum-Free and Solvent-Free Deposition of Electrodes for Roll-to-Roll Fabricated Perovskite Solar Cells"). | |

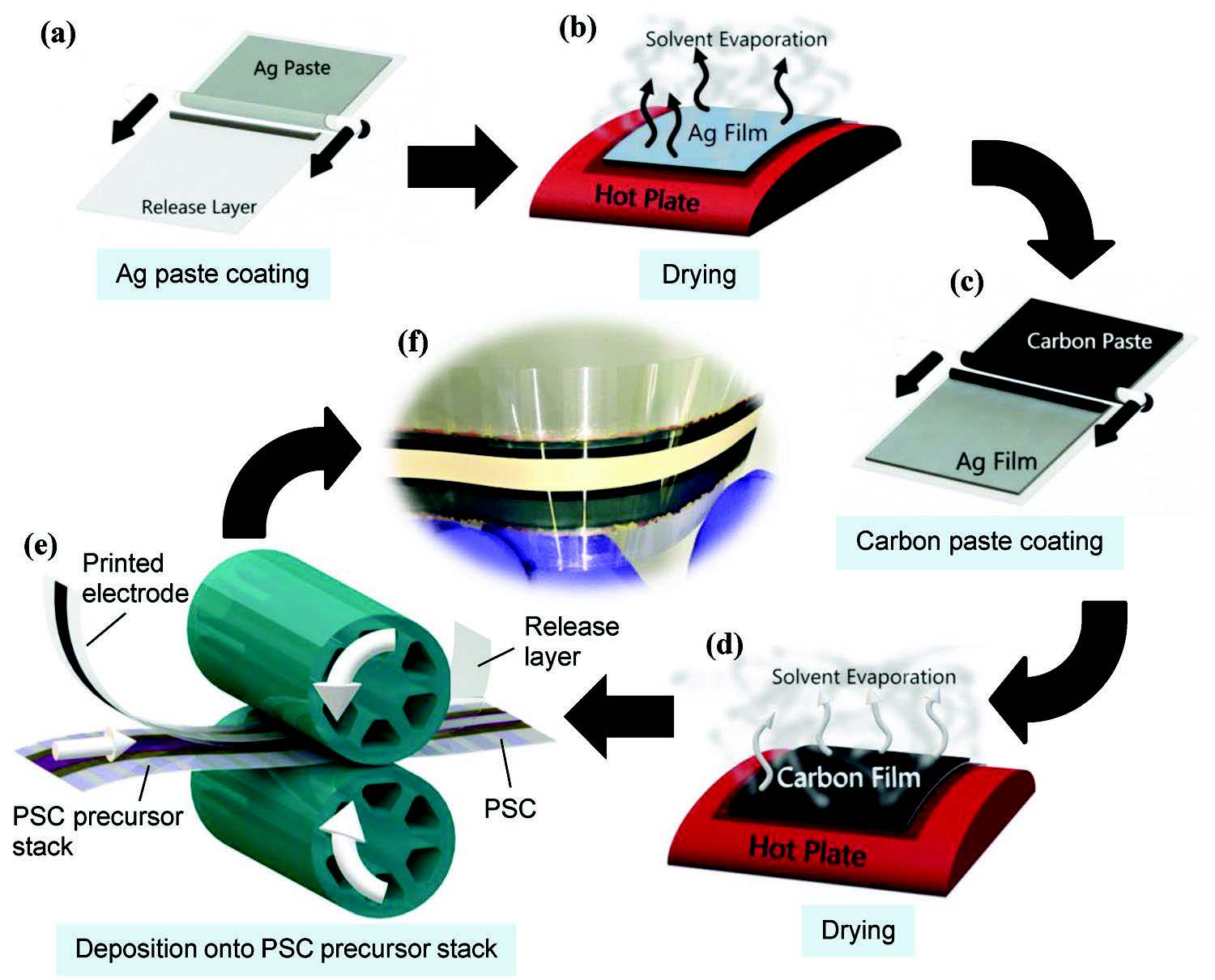

| This new electrode deposition method involves the deposition of carbon and silver on a detachable plastic (PET) substrate first, with the dried electrode then pressed onto the top of the perovskite solar cell. The PET layer is then removed and can be reused. | |

|

|

| Flow-chart illustrating the fabrication steps of the flexible printed electrodes: a) coating of Ag paste onto nonstick side of release layer, b) drying of the Ag coating, c) coating of carbon-based paste onto dried Ag layer, d) drying of the carbon-based coating, e) dry press deposition of the printed bilayer electrode to the roll-to-roll-fabricated PSC precursor stack (up to the hole-transport layer) in a calendar press, and f) photo of the complete PSC device. (Reprinted with permission from Wiley-VCH Verlag) | |

| This new method allows the electrode layer to be deposited without the need for solvents or heat treatments that potentially damage the perovskite layer – an important milestone toward the commercial viability of perovskite solar cells. | |

| Using this novel technique, a team of researchers led by Dr. Mei Gao, a Principal Research Scientist in CSIRO's Printed PV team, demonstrated devices displaying power conversion efficiencies (PCEs) of up to 16.7% for the fully printed devices – the highest reported efficiencies for all roll-to-roll processed perovskite devices (this compares to 17.4% for devices having conventional evaporated gold back electrodes). | |

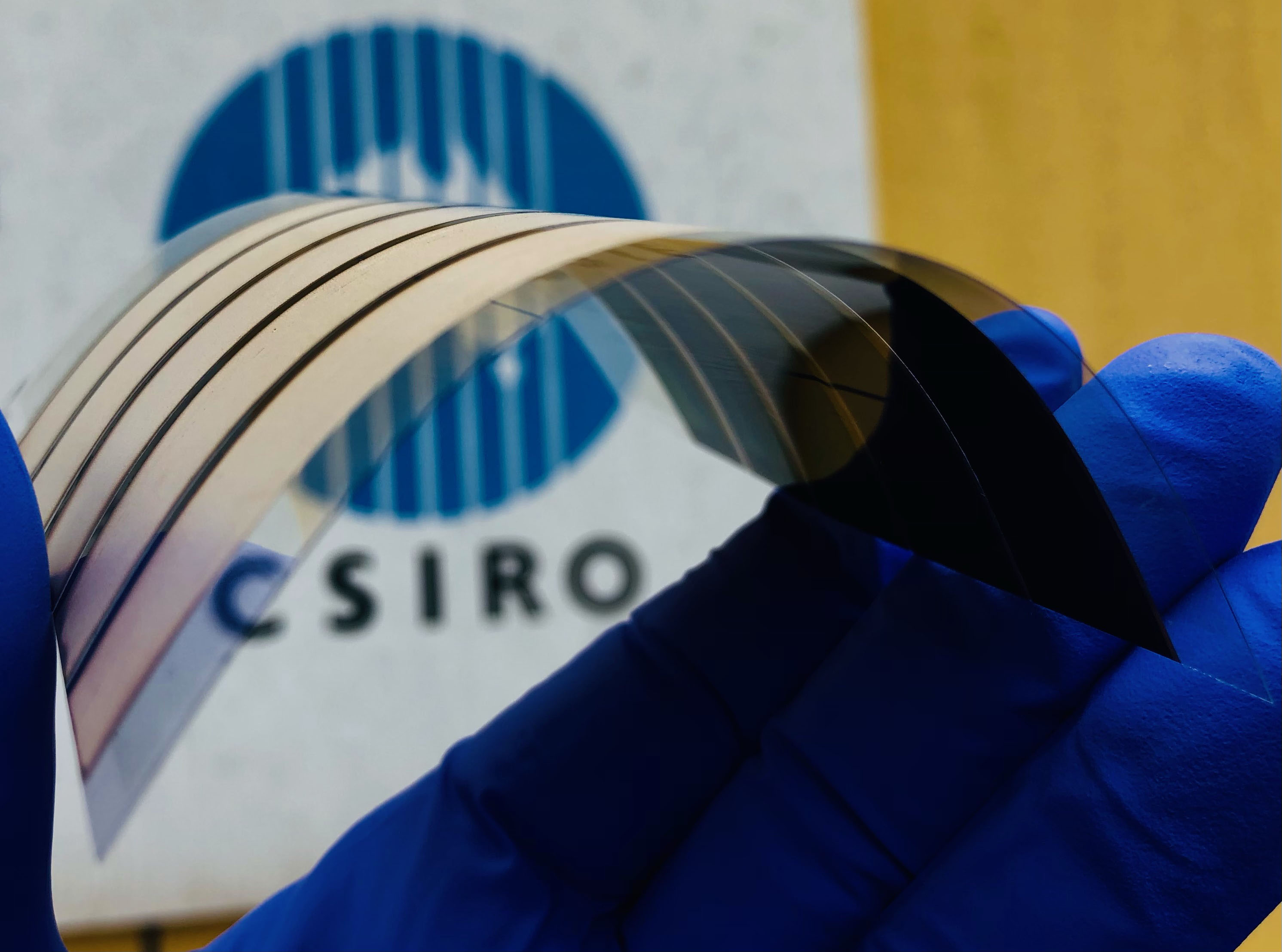

| "The vacuum-free and roll-to-roll compatible printed electrode deposition avoids the degradation mechanisms that can occur when electrode materials are directly deposited," Printable PV team leader Dr Gao tells Nanowerk. "Our flexible perovskite solar cells with printed electrodes also exhibit outstanding bending durability, with marginal loss of PV performance after 3000 cyclic bends, indicating their suitability for a wide range of flexible electronic applications." | |

| Usually, depositing a solvent-based paste or ink directly as the final layer in a printed perovskite solar cell is detrimental to the performance of the solar cells due to solvent leaching from the paste/ink into other printed layers, or due to the requirement of heating the devices during the drying or curing processes. | |

| Consequently, the range of pastes and inks that can be used for the printed electrode is greatly restricted by the limited number of 'perovskite friendly' solvents, which is one of the factors that has constrained the highest efficiency reported for a flexible roll-to-roll fabricated perovskite solar cell with a printed electrode to only 10%. | |

| Enter the electrode dry press deposition method developed by the CSIRO team – perfectly suitable for the roll-to-roll fabrication of flexible printed perovskite solar cells under ambient laboratory conditions. | |

|

|

| The Printable PV team at CSIRO is currently working on using this new electrode deposition technique (Dry Press Deposition) in scaling the roll-to-roll printable perovskite PV technology to expedite the commercialization of large-area perovskite modules. (Image courtesy of the researchers) | |

| "We fabricate a printed silver/carbon electrode on an easily detachable substrate before transferring the electrode onto a printed perovskite stack via dry press deposition," CSIRO Research Scientist and project leader Dr Hasitha Weerasinghe explains. "This enables the top electrode of the device to be deposited onto the perovskite stack without the underlying printed layers being exposed to heat or solvents." | |

| The CSIRO team is now exploring how to improve the stability of the perovskite cells by making them more resistant to moisture and oxygen. They are also investigating how to scale this newly developed dry press deposition technique in order to demonstrate large-area perovskite-based solar modules and to manufacture printed solar cells on an industrial scale. | |

| "Our innovation is a giant step toward solar-powered everyday consumer goods, from smartwatches and wearables to solar-powered tents, and may even replace disposable batteries in household items like remote controls," Monash PhD candidate and co-researcher Luke Sutherland concludes. "These lightweight flexible solar modules with their outstanding power conversion efficiency and the high power-to-weight ratio also fit well for powering electric vehicles and might even be a promising candidate for next-generation space photovoltaic technology." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|