| Sep 05, 2023 | |

Unlocking the full potential of MXenes for next-generation e-textiles |

|

| (Nanowerk Spotlight) Electronic textiles, or e-textiles, are fabrics that integrate electronics and other functional materials to add advanced capabilities beyond basic clothing. Prior research has incorporated conductive nanomaterials like carbon nanotubes into textile fibers or coatings to create fabrics with useful properties such as conductivity, sensing, energy storage, and electromagnetic shielding. But manufacturing scalable e-textiles in an efficient and cost-effective manner remains challenging. | |

| Recently, a class of two-dimensional metallic carbide materials called MXenes have shown potential for wearable technologies and e-textiles due to exceptional electrical conductivity and flexibility. MXenes have been a subject of interest in the scientific community due to their exceptional electrical and mechanical properties. They are highly conductive, flexible, and can be easily processed in water, making them a suitable candidate for electronic applications. However, the utilization of MXenes has been hindered by several challenges, including the high cost of their precursor material, known as MAX, and their poor durability in extreme environments. | |

| Only a small portion of the MXene precursor material has been utilized in e-textile fabrication thus far. | |

| Now, researchers from Shandong University in China have reported in Advanced Functional Materials ("From “100%” Utilization of MAX/MXene to Direct Engineering of Wearable, Multifunctional E-Textiles in Extreme Environments") a novel strategy to fully maximize the use of MXenes to fabricate multifunctional e-textiles in a simple, affordable, and scalable way. Their approach converts previously discarded MXene waste into functional inks for durable, high-performance fabrics. | |

|

|

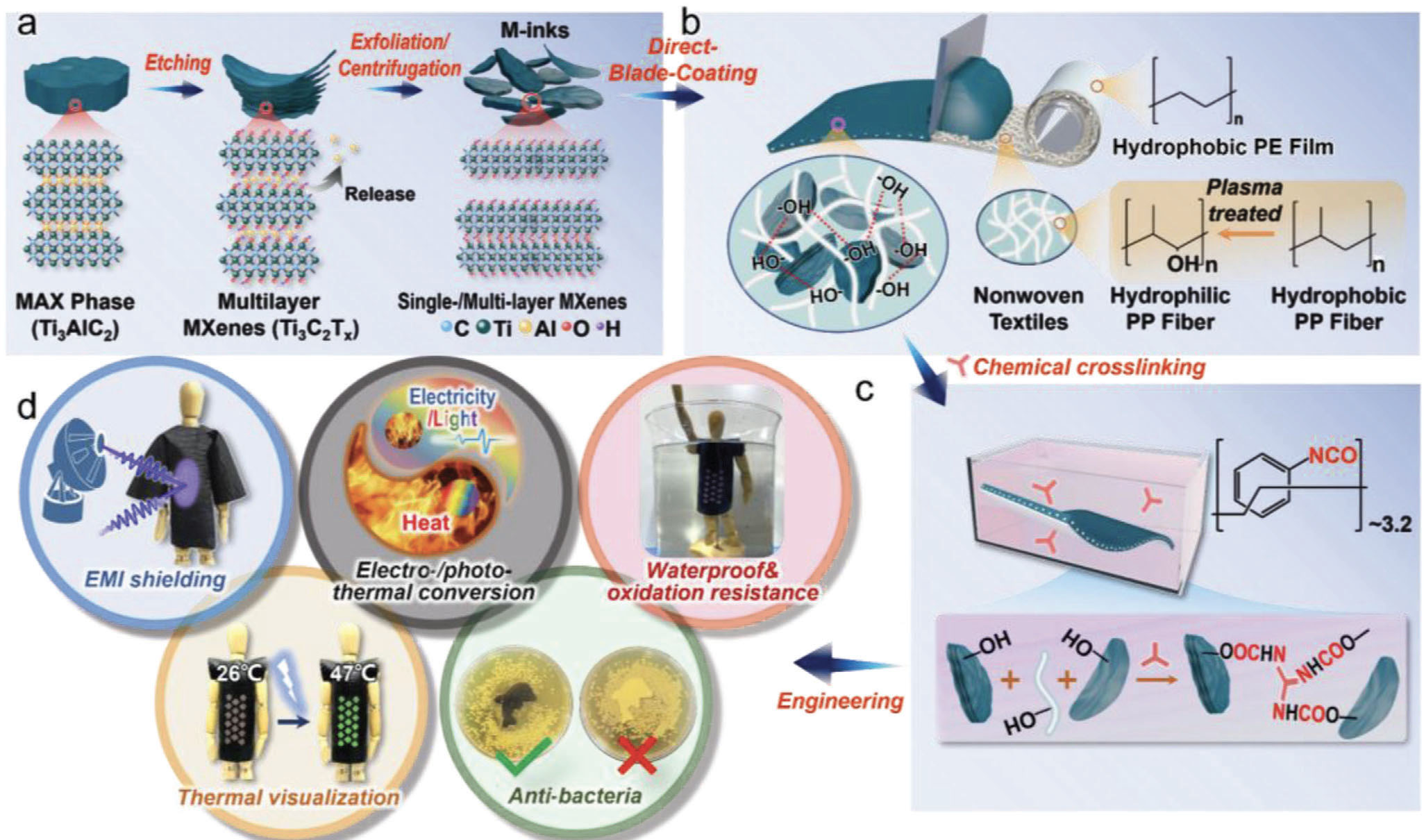

| Schematic for the manufacturing process and characterization of cross-linked MXS (C-MXS) e-textiles. a) Preparation of M-inks. b) The manufacturing of MXS e-textiles by direct-blade-coating (DBC). c) The chemical crosslinking treatment of MXS e-textiles. d) Engineering of C-MXS e-textiles. (Reprinted with permission from Wiley-VCH Verlag) | |

| MXenes are a relatively new class of two-dimensional metallic carbide and nitride materials that have shown promise for applications including energy storage, electromagnetic shielding, and wearable electronics. They are made by etching away certain layers from a precursor material called MAX. But a major challenge has been that typical MXene preparation methods utilize only 10-20% of the MAX, wasting large amounts of unused material. | |

| The new approach devised by the team aims to utilize 100% of the MAX to make multifunctional e-textiles in a cost-effective and environmentally friendly manner. The team collected all of the unused sediment from MAX etching, which contains a mixture of partially etched MAX, multilayer MXene sheets, and some single layer MXene flakes. This sediment, along with any remaining single layer MXene, was concentrated into a viscous, additive-free ink. | |

| The ink was then used in a simple direct blade coating method to coat flexible, porous polyethylene/polypropylene nonwoven textiles. The abundant functional groups on the MXene materials allowed them to firmly adhere to the textile fibers, forming a flexible conductive fabric. To further enhance its properties, the researchers applied a chemical cross-linking treatment. This improved the hydrophobicity, stability, and oxidation resistance of the e-textile. | |

| Testing demonstrated the exceptional capabilities of the multifunctional fabric. One of the standout features of these MXene-based e-textiles is their EMI shielding capability. By tuning the MXene content, the electrical conductivity and electromagnetic shielding effectiveness could be widely controlled. An ultra-broadband shielding effectiveness of over 58 dB was achieved from 8.2 to 40 GHz, meeting and exceeding commercial requirements. In our increasingly connected world, the ability to shield electronic devices from electromagnetic interference is crucial. The e-textiles developed in this study demonstrated significant EMI shielding effectiveness, outperforming other materials. This makes them highly relevant for applications in defense, aerospace, and even everyday wearable electronics. | |

| Another noteworthy aspect is the e-textile's electrothermal and photothermal performance. Imagine a jacket made from this material that not only keeps you warm but can also deice itself in extreme winter conditions. The MXene e-textile could quickly and efficiently convert electricity into heat, enabling thermal management, deicing, and wearable heating applications. It additionally exhibited excellent photothermal properties under light irradiation, heating rapidly from room temperature up to 85 °C under safe conditions. This allowed the fabric to kill bacteria, displaying a potent antibacterial effect. | |

| The researchers also emphasized the durability and reliability of these e-textiles. Through a chemical cross-linking process, the e-textiles were endowed with improved hydrophobicity, water resistance, and oxidation stability. This ensures that the material can withstand harsh conditions, further broadening its range of potential applications. | |

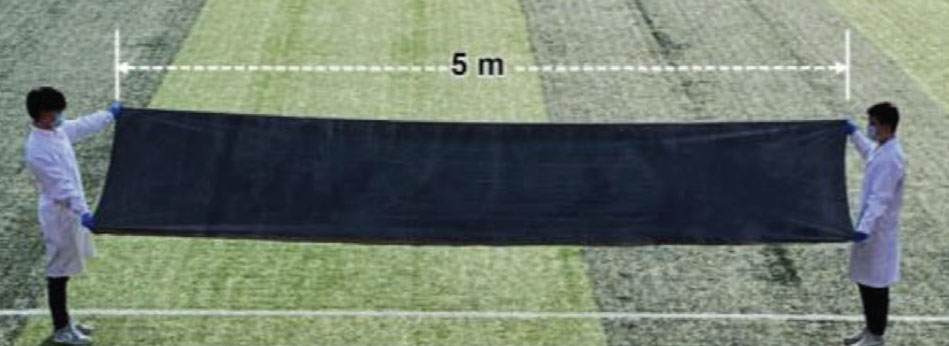

| The study is not just a theoretical exercise; it offers practical solutions. The researchers demonstrated the scalability of their approach by producing a large-area e-textile, highlighting its commercial viability. The process is not only scalable but also cost-effective, addressing one of the major hurdles in the widespread adoption of such advanced materials. | |

|

|

| Photograph of a large-area freestanding C-MXS e-textile. (Reprinted with permission from Wiley-VCH Verlag) | |

| The researchers emphasize that their fabrication method enables the scalable and affordable production of MXene e-textiles using the entire yield from MAX etching, without any material waste. The simple direct coating approach did not require complex or costly processing. The resulting flexible, conductive fabric displayed exceptional multifunctional capabilities under a wide range of conditions. Importantly, the chemical cross-linking treatment endowed the material with excellent stability and reliability, maintaining high performance even after extensive mechanical deformations and in harsh environments. | |

| This work demonstrates the tremendous potential of utilizing MXenes in an optimal manner to create e-textiles with integrated, useful functions spanning electromagnetic shielding, heating, and antibacterial effects. The robust performance, simple fabrication technique, and low cost point to real-world applications in wearable electronics, thermotherapy, medical care, defense, aerospace, and more. | |

| Moving forward, further research can build on these findings to fully capitalize on MXenes and translate their exciting properties into practical e-textile technologies. The long-term impact of this strategy could be the sustainable mass production of smart fabrics that can sense, adapt, and respond to their environment. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|