| Sep 20, 2023 | |

Scientists mimic the extracellular matrix with novel biomimetic material |

|

| (Nanowerk Spotlight) The extracellular matrix (ECM) is the complex network of proteins and sugars that provides structural and biochemical support for surrounding cells in the human body. This dynamic scaffolding regulates cell behaviors and functions, facilitating processes like cell migration, proliferation and differentiation. Scientists have long aimed to recreate the structural intricacy and biological activity of the ECM for diverse biomedical applications from regenerative medicine to in vitro modeling. Now researchers at Deakin University in Australia have made a significant leap towards that goal. | |

| In a new study published in Nano Letters ("Facile In Situ Assembly of Nanofibers within Three-Dimensional Porous Matrices with Arbitrary Characteristics for Creating Biomimetic Architectures"), the team reports a novel manufacturing strategy to generate 3D biomimetic matrices that closely emulate the ECM’s nanoscale architecture and multilevel porosity. Their facile approach enables tunable control over the matrices’ mechanical strength, hydrophilicity and bioactivity as well. | |

| “It is challenging to recapitulate the natural extracellular matrix’s hierarchical nano/microfibrous three-dimensional structure with multilevel pores, good mechanical and hydrophilic properties, and excellent bioactivity for designing and developing advanced biomimetic materials,” Dr. Linpeng Fan from the Institute for Frontier Materials at Deakin University, first author of the study, explains to Nanowerk. “This work reports a new facile strategy for the scalable manufacturing of such a 3D architecture.” | |

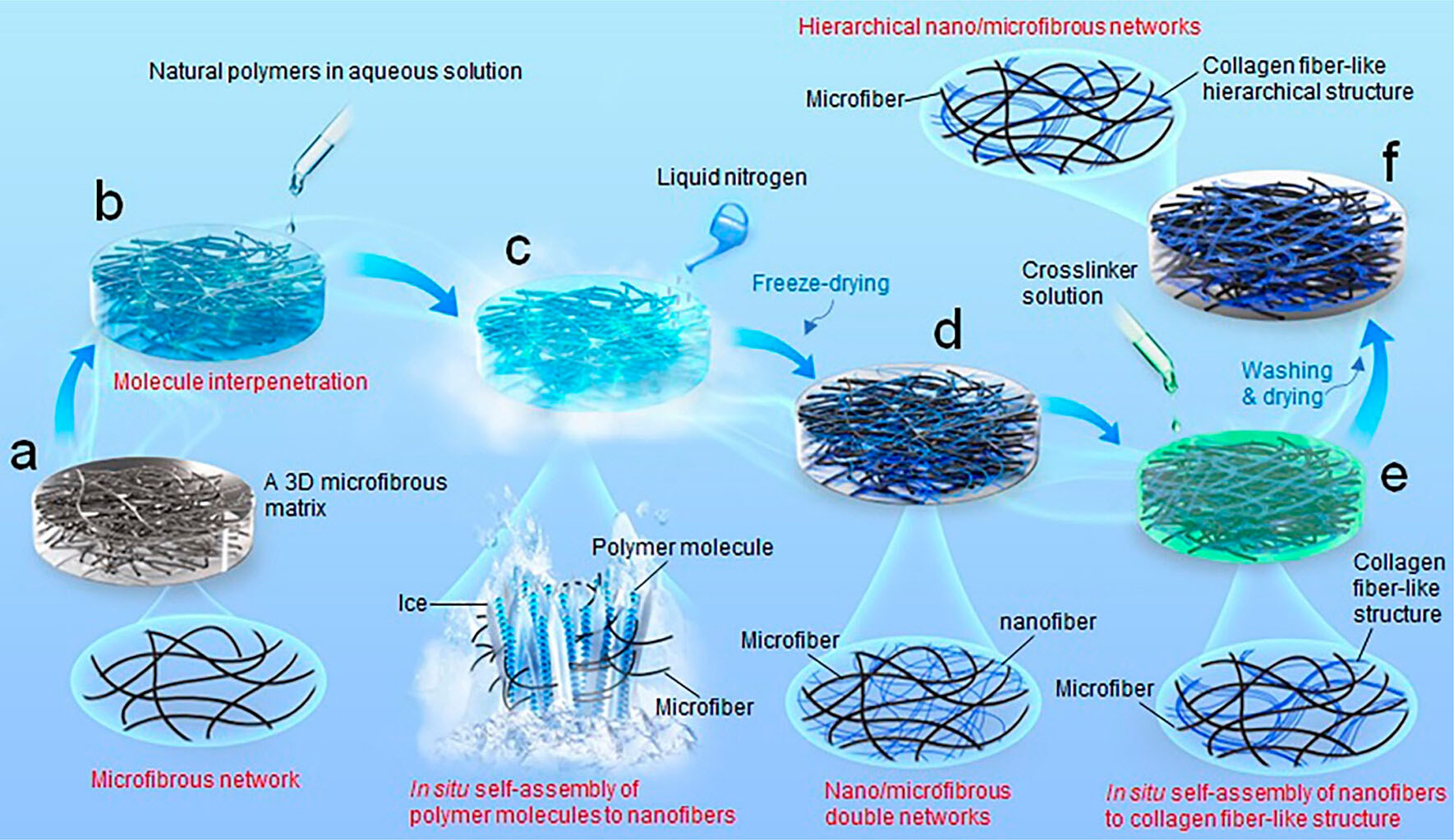

| The researchers’ strategy centers on the directed self-assembly of natural polymer nanofibers within an existing microfibrous matrix. They interpenetrate a 3D microfibrous scaffold – such as nonwoven polypropylene or a medical gauze fabric – with an aqueous polymer solution like alginate or silk fibroin. Freezing this impregnated matrix in liquid nitrogen induces the rapid formation of ice crystals that template the nanoscale alignment of the polymers into fibers in the larger matrix pores. | |

|

|

| Schematic illustration of scalable manufacturing of biomimetic 3D nano/microfibrous matrices by facile and eco-friendly in situ assembly of nanofibers. (a) 3D microfibrous matrix. (b) 3D microfibrous matrix interpenetrated with natural polymers. (c) In situ self-assembly of polymer molecules into nanofibers in the 3D microfibrous matrix. (d) 3D matrix with nano/microfibrous double networks. (e) In situ self-assembly of nanofibers into the collagen fiber-like structure in the 3D nano/microfibrous matrix. (f) 3D biomimetic matrix with hierarchical nano/microfibrous networks. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The resulting composite displays an intricate double network of interlaced microfibers and nanofibers. With alginate for instance, nanofibers just ∼250 nm in diameter self-assemble within the polypropylene microfibrous matrix. The researchers demonstrate the versatility of this in situ nanofiber synthesis, forming nanofibrous networks from alginate, mixtures of alginate and gelatin as well as silk fibroin using different microfibrous substrates. | |

| To further recapitulate the collagen fibers' structure of the ECM, the team crosslinks the composite with a calcium chloride/ethanol solution. This treatment triggers the bundled self-assembly of aligned nanofibers into distinct hierarchical structures resembling natural collagen fibers. Tuning the initial polymer concentration controls the density of these collagen fiber-like bundles. | |

| This two-step process generates biomimetic matrices with a striking likeness to the ECM morphology. The matrices display an interconnected combination of micro and nanoscale pores ideal for cell infiltration and substance transport. Their mechanical strength is also tunable based on the identity of the microfibrous scaffold and the density of nanofiber networks within it. With sufficient alginate nanofibers for instance, compressive modulus increased from 17 to 24 kilopascals. | |

| Perhaps most impressively, the researchers’ strategy imbues the composites with durable hydrophilicity and pronounced bioactivity as well. Incorporating alginate nanofibers made the normally hydrophobic polypropylene matrices absorb water readily. Skin fibroblast cells seeded on alginate nanofiber/polypropylene microfiber matrices also showed significantly higher viability and more collective growth reminiscent of natural tissues compared to cells on just the polypropylene scaffold. | |

| According to Fan, these exciting results highlight the potential of their manufacturing method to generate customized biomimetic matrices for diverse applications. “With this strategy, the prepared 3D alginate/PP matrix presented the ECM-mimicking nano/microfibrous feature with the collagen fiber-like hierarchical structure, interconnected multilevel pores, good mechanical property, and inherently high hydrophilicity and bioactivity,” he says. | |

| By facilitating the self-assembly and bonding of a broad range of natural or synthetic polymers within existing microstructures, their technique offers a facile way to design advanced biomaterials with precisely controlled composition and architecture. From lab-grown tissues to bioreactors and biosensors, these robust and bioactive matrices could form the foundational scaffolding to enable emerging technologies across medical and biotechnology fields. | |

| "Replicating the extracellular matrix has proven an elusive materials science challenge," Fan concludes. "But leveraging self-assembly and interfacial interactions between nano- and microstructures, our new manufacturing strategy provides key insights and a flexible platform to recreate the ECM’s dazzling intricacy and dynamic functionality." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|