| Sep 27, 2023 | |

3D Prints join the dark side and vanish |

|

| (Nanowerk Spotlight) 3D printing, also known as additive manufacturing, has opened new doors in design and manufacturing. The greatest resolution is achieved using a technique called direct laser writing (DLW), which focuses a laser into a photosensitive material to solidify microscopic 3D structures. One of the challenges in 3D printing is the static nature of the printed structures, limiting their adaptability to changing conditions or requirements. | |

| To expand applications, scientists want to make 3D printed microstructures responsive to stimuli like light. This would allow erasing or stabilizing parts of a structure on-demand. Applications could include degrading tissue scaffolds inside the body, removing support materials from complex architectures, or introducing controlled movement. | |

| Reporting their findings in Advanced Functional Materials ("3D Printed Microstructures Erasable by Darkness"), researchers from Germany and Australia have now pioneered a light-responsive resist for direct laser writing. A "light-responsive resist" is a type of material used in 3D printing that reacts to light. When exposed to light, this material becomes solid and forms a structure. | |

| The unique feature of a light-responsive resist is that it can change its state based on light exposure. For example, it can remain stable and hold its shape under certain lighting conditions, but it may dissolve or break down when the light is turned off or blocked. This characteristic allows for the creation of 3D printed structures that can be altered or erased post-production by simply changing the light conditions. | |

|

|

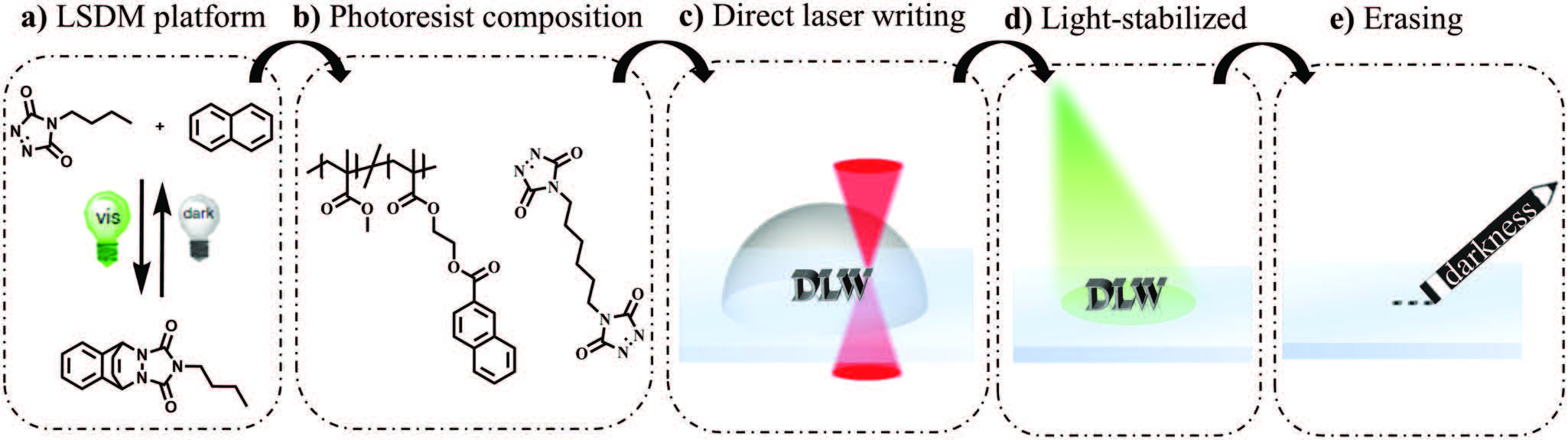

| General overview of the presented study. a) The light-stabilized dynamic materials chemistry platform, which relies on the visible-light-driven dynamic cycloaddition reaction of TAD and naphthalene. b) The light-stabilized dynamic materials platform incorporated into a photoresist for DLW. c) 3D direct laser writing of microstructures, as well as d,e) their light-stabilized properties and subsequent erasing when exposed to darkness, respectively. (Reprinted with permission from Wiley-VCH Verlag) | |

| The researchers' material is based on the photo-triggered formation and dissociation of chemical bonds. Illuminated with green light, the bonds stay connected like a net holding up a structure. In darkness, the net unravels as the bonds break apart, erasing the shape. | |

| The team produced several light-responsive polymers by attaching light-sensitive chemical groups onto longer polymer chains. They then used these to print arrays of microscopic 3D stars. Without light, the stars degraded over several days when immersed in solvent, which accelerates the unraveling. Under constant green illumination, the structures remained intact. | |

| By adjusting the laser power during printing, the scientists controlled how quickly the stars degraded in darkness afterwards. Higher power made more connections in the net, slowing disassembly. This demonstrates tunable responsiveness without altering the resist chemistry. | |

| The researchers also printed multi-material scaffolds by combining their new resist with a conventional one. The conventional resist formed the base while the new one printed removable supports and bridges. When kept in solvent darkness, the bridges selectively degraded over time until the scaffold collapsed. | |

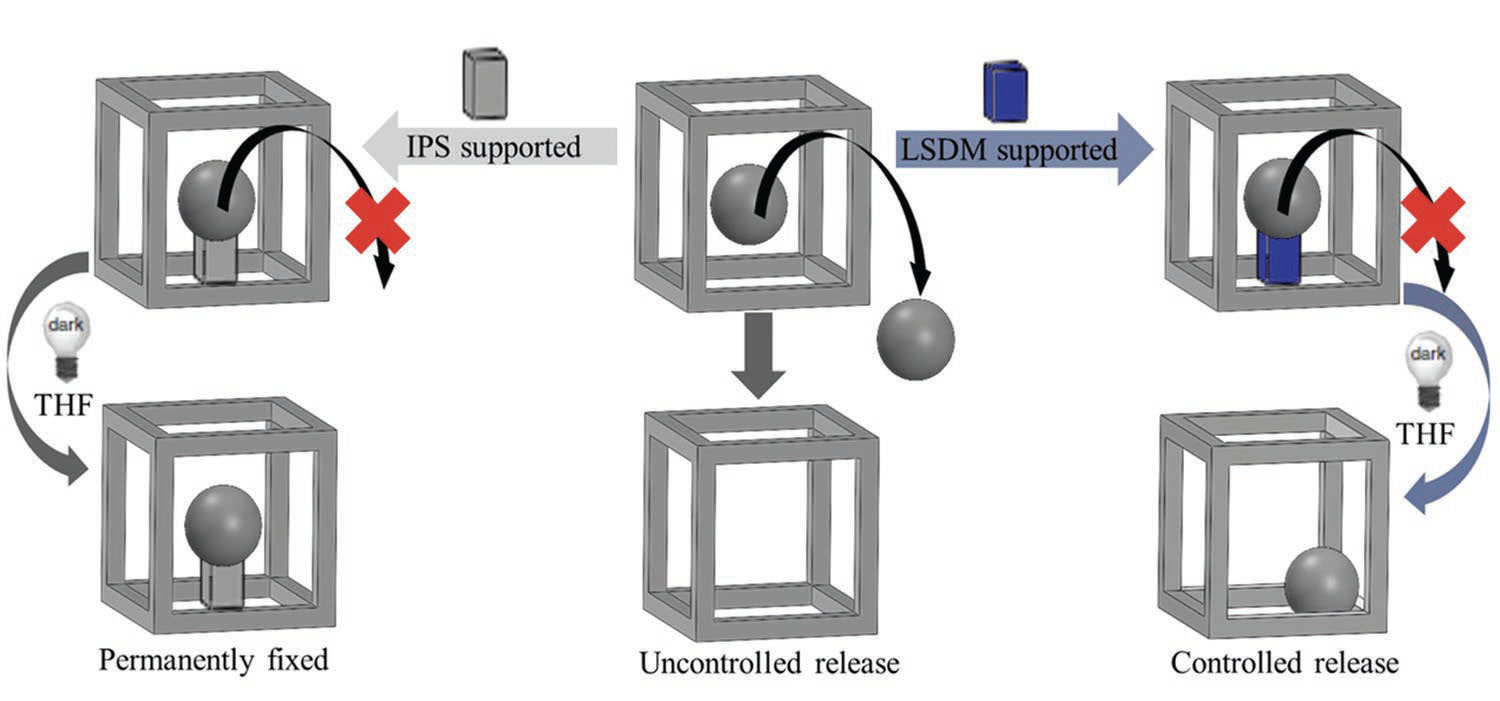

| In another demonstration, the team printed a microscopic ball inside a box supported by a block of their photo-responsive material. In darkness, the support disintegrated in a controlled manner, eventually releasing the ball to roll free inside the box. | |

|

|

| Overview of the ball-in-a-box model utilized to demonstrate unprecedented moving features. When the ball-in-a-box is printed without support material underneath the ball, it is uncontrollably lost during development (center). Although a support block constructed from the commercial resist (IPS) prevents the ball from escaping during development, it is permanently attached to the support block (left). In contrast, a support block constructed from the LSDM-based resist provides a temporary locking mechanism, whereby degradation of the support block releases the ball in a controlled fashion (right). (Reprinted with permission from Wiley-VCH Verlag) | |

| Usually, support structures must be actively removed from 3D printed constructs using additional solvents or mechanical force. The researchers say their resist provides a built-in self-destruct mechanism requiring no extra steps. This enabled the unprecedented printing of their moving ball structure. | |

| Overall, the study establishes a resist for high-resolution 3D printing that simplifies integrating responsive behavior into microstructures. Controlled light can stabilize or destabilize parts made from the material post-production. Without altering the resist itself, the printing process programs the lifetime before degradation in darkness. | |

| The technology could allow 3D printing reconfigurable electronics, removable supports for fabricating complex shapes, and scaffolds or micromachines with built-in responsiveness. The researchers suggest medical applications like controlled cell release from printed tissue scaffolds that dissolve at a predictable pace after implantation. The simplicity of printing then erasing with light versus darkness makes the advance highly accessible. | |

| 3D printing already facilitates designs straight from the imagination. While 4D printing technology, which involves creating objects that can change shape or properties over time in response to external stimuli like heat, light, or moisture, is already established, the introduction of light and darkness responsiveness adds a groundbreaking layer of control. This innovation enables precise and on-demand alterations to microstructures post-production, simply by altering light exposure. The ability to erase or stabilize structures with light or darkness paves the way for advanced applications in various fields, enhancing the versatility and functionality of small-scale manufacturing. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|