| Jan 22, 2024 | |

Ultra-thin ceramic membrane for unprecedented imaging of chemical reactions |

|

| (Nanowerk Spotlight) The dynamics of chemical reactions central to energy innovations unfold at nanometer lengths - a scale too small to directly witness in atomistic detail, obscured by limitations of observation tools. Scientists could only speculate based on indirect evidence rather than visually verifying the intricate molecular dance underlying mechanisms they aim to optimize. | |

| Now, researchers at Northwestern University report in Science Advances ("Ultrathin silicon nitride microchip for in situ/operando microscopy with high spatial resolution and spectral visibility") a transformative fabrication breakthrough that finally equips scientists with micro view portals thin enough to expose chemical processes at fundamental length scales. Ultra-thin silicon nitride membrane windows just 10 nanometers thick provide crisp imaging and chemical analysis that previous research platforms intrinsically blurred. Supported by rigid silicon backbones and spatially confined to small but abundant viewing areas, these stable membranes overcome decade-long struggles to balance miniscule thickness with resilience. | |

| The thin windows facilitate tremendous resolution improvements for enclosed liquid and gas nanoreactors inside specialized electron microscopes. Detailed before-and-after characterizations underscore substantially enhanced imagery, chemical signatures and diffraction data compared to conventional thicker enclosures. | |

|

|

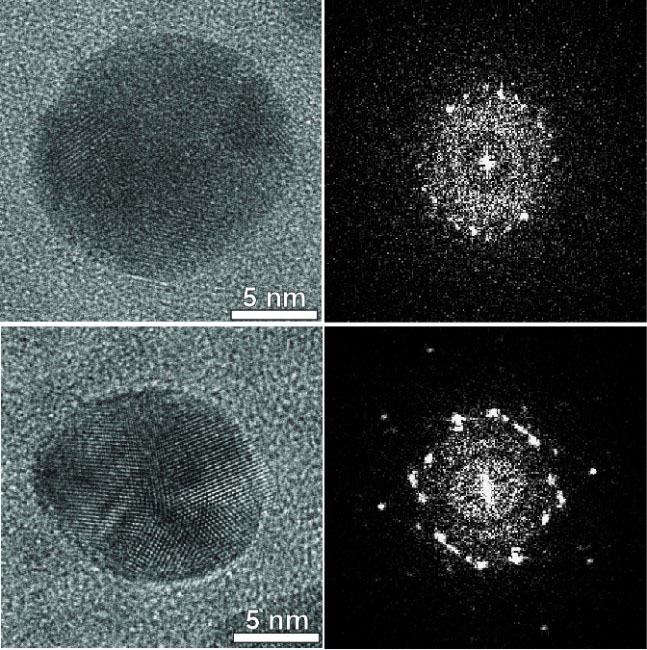

| High resolution transmission electron microscope images of Au nanoparticles before (above) and after (below) encapsulation. (Image: Northwestern University) | |

| The study also demonstrates capacity to differentiate rapid reaction dynamics down to steps unfolding in microseconds. Scientists anticipate direct nano-views of mechanisms governing catalysis, gas sensing, microelectronics and more will open new investigative vistas to accelerate discoveries through at-last unobstructed observation. | |

| In the study, the researchers demonstrated the practical applications of the ultra-thin silicon nitride membranes through specific experiments. For instance, they enclosed gold nanoparticles inside gas cells with membranes of varying thicknesses. This led to a substantial improvement in imaging clarity, distinctly resolving the gold lattice structures and crystal orientations. | |

| Additionally, they utilized the technology to observe palladium nanocube reactions. The nanocubes expanded and contracted rapidly upon hydrogen gas exposure, a process captured in real-time. These experiments underline the membrane's capacity to facilitate high-resolution imaging and analysis, crucial for understanding nanoscale phenomena in various scientific fields. | |

| The stubborn barrier that long hindered progress was the silicon nitride membrane enclosing chemical samples inside electron microscopes. Although strong and transparent, commercial silicon nitride membranes measure 100 nanometers thick - far thicker than the nanoscale catalyst particles under study. Like looking through frosted glass, the thick membranes blur imagery and scatter electrons, preventing clear observation. Scientists could only speculate based on indirect evidence, rather than directly visualizing atomic configurations and bonding during chemical reactions. | |

| The new study demonstrates that by strategically reinforcing an ultra-thin 10 nanometer silicon nitride membrane with rigid silicon supports, the enclosing material can be made 20 times thinner than previous possible while remaining stable against pressure and electron beam damage. This enables tremendous improvements in imaging resolution, chemical analysis and diffraction data from within specialized “nanoreactor” chambers inside transmission electron microscopes. | |

| Not only does the advancing fabrication technique improve existing microscope setups, but it also makes practical whole new classes of experiments to uncover nanoscale intricacies in fields from catalysis to microelectronics to renewable energy. The study provides exceptional visualizations of nanoparticle catalysts and characterizes rapid hydrogen absorption dynamics in palladium nanocubes down to reaction steps occurring in microseconds. | |

| “With our strategy to fabricate ultra-thin but robust membranes, we can now get exact visual confirmation of structural configurations and chemical transformations happening at fluid-solid interfaces that were impossible to differentiate previously,” explained study coauthor Vinayak Dravid. | |

| Silicon nitride membranes are the established standard for enclosing nanometer-scale liquid and gas chambers inside electron microscopes, allowing scientists to examine materials within realistic atmospheric environments. But those membranes measure 50 to 100 nanometers thick, whereas the catalyst nanoparticles and atomic clusters under examination are often only 1 to 5 nanometers wide. Imaging through such thick windows is akin to viewing an object at the bottom of a swimming pool. | |

| While some microscopes use “open cell” systems maintaining pressure gradients to simulate environments, the closed cell approach offers simplicity, lower costs and amenability to a wider range of liquids and vapor conditions. If not for limitations imposed by membrane obscurity and instability at lower thicknesses, closed cell systems would present ideal nanoscale reactors to unlock mysteries of interfacial reactions with electron imaging and spectroscopy. | |

| Researchers previously established that reducing membrane thickness improves resolution, but existing fabrication strategies faltered below 30 nanometers. Without support, such ultra-thin membranes sag, wrinkle and rupture under microscopic pressure gradients and electron beam irradiation. Earlier attempts to implement smaller sections of thin membranes still covered much of the viewing area. None have matched commercial viability for practical widespread adoption until now. | |

| The Northwestern team applied unique expertise in specialized doping processes to construct a rigid honeycomb of heavily boron-doped silicon supporting an open mesh of 10 nanometer silicon nitride regions just large enough to permit imaging. Simulations and physical testing verified that their back-supported ultra-thin membranes withstand over five times atmospheric pressure and direct electron beam exposure orders of magnitude beyond typical imaging doses before degrading. | |

| “The strategy of having small viewing windows with thin membranes encompassed by strong supports removes previous barriers concerning stability and scalability,” explained Kunmo Koo, first author of this study. | |

| To underscore the performance gains in clarity enabled by their ultra-thin membranes, the researchers enclosed identical samples of ten nanometer gold nanoparticles inside gas cells with varying membrane thicknesses. Contrast improved substantially over commercially available membranes, distinctly resolving gold lattice structures and crystal orientation. Thinner membranes also reduced background noise to boost signal fidelity for elemental spectroscopy. Characteristic chemical fingerprints emerged that were previously undetectable in electron energy loss spectra of various gas species at the low 100 torr pressures relevant to many catalytic reactions. | |

| Koo also demonstrated the system by capturing electron diffraction data depicting palladium nanocube expansion and contraction as they rapidly absorbed and released hydrogen gas. Within the enclosed environment at room temperature and standard atmosphere, palladium lattice spacing expanded four percent upon hydrogen exposure. Through in-situ measurements every 0.3 seconds, the team characterized diffusion speeds and adsorption dynamics revealing the specific rate-limiting steps in hydrogen storage processes. The advances unpack long shrouded details with implications to guide design of improved hydrogen storage materials. | |

| “With our widely implementable strategy that finally places high resolution molecular imaging into standard practice, we envision researchers will unleash all sorts of innovative investigations into fluid-surface interactions to uncover new catalyst paradigms, novel microelectronics and more,” Koo said regarding ongoing expansion of this approach. | |

| The study authors are currently fabricating gas cells and liquid cells based on the ultra-thin membranes for users across Northwestern University. They believe that the capacity to affordably equip transmission electron microscopes with thin window reactors on a broad scale will prove as game changing of a standardization for nanoscience as PCR machines enabling DNA analysis. | |

| “Many fields from renewable energy tech to microelectronics can gain fundamental insights from directly visualizing molecular processes that were impossible to discern clearly before,” concluded Dravid. “We’re excited to see what new discoveries will emerge thanks to finally overcoming this stubborn limitation, just as PCR unlocked genetics.” | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|