| Jan 24, 2024 | |

New smart materials advance chemical signaling between robots |

|

| (Nanowerk Spotlight) Living organisms utilize sophisticated chemical signaling to share information, locate mates, and defend territories. Harnessing similar abilities could revolutionize robotic perception, collaboration, and functionality. However, previous artificial chemical communication attempts faced limitations: Materials lacked integrated send, receive and sense capabilities; Control over chemical release timing and volumes was insufficient; Transfer range restrictions hindered practical applications; Cascading multi-step reactions were infeasible. An enduring challenge has been developing adaptable materials that emulate biological ingenuity across diverse environments. | |

| Recent breakthroughs in liquid crystal polymer networks (LCNs) now show promise in overcoming these barriers. LCNs are programmable smart materials which change shape when exposed to light. Reporting their findings in Advanced Materials ("Facilitating Interskin Communication in Artificial Polymer Systems through Liquid Transfer"), a research team from Eindhoven University of Technology has created LCN layers which mimic skin. These artificial skins can send, receive and sense chemical signals on demand. The materials demonstrate enhanced dynamic control, signaling versatility, reactive functionality and sensory feedback. | |

|

|

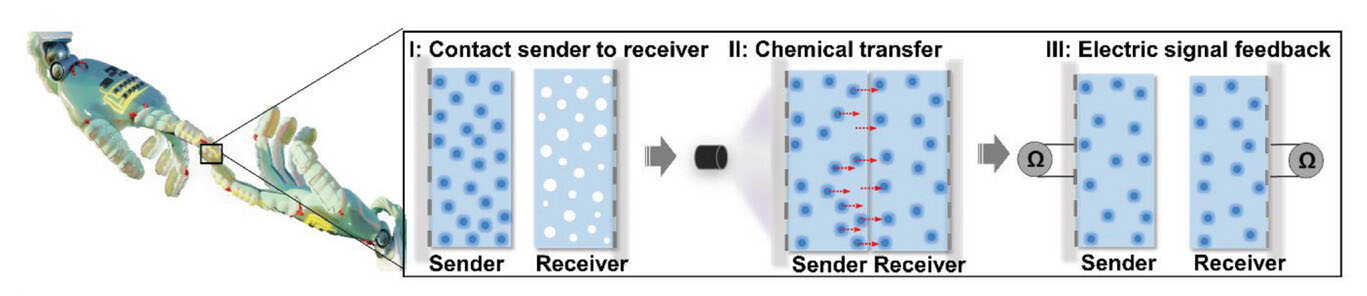

| Schematic illustration of the process of chemical communication, including information transfer, reception, and sensing. (Reprinted with permission by Wiley-VCH Verlag) | |

| The team’s approach integrates light-triggered chemical release with electric charge detection. The LCN skin layers contain specifically designed pores which are filled with solution containing ionic compounds. UV light exposure causes the skin to contract, pushing liquid out through the pores onto another nearby surface. This transfer process turns on an LED light, signaling successful transmission. The emitted liquid also changes the electrically measured resistance on the receiving skin. Resistance values correlate to transmitted liquid volumes, enabling exact chemical release quantities to be sensed. | |

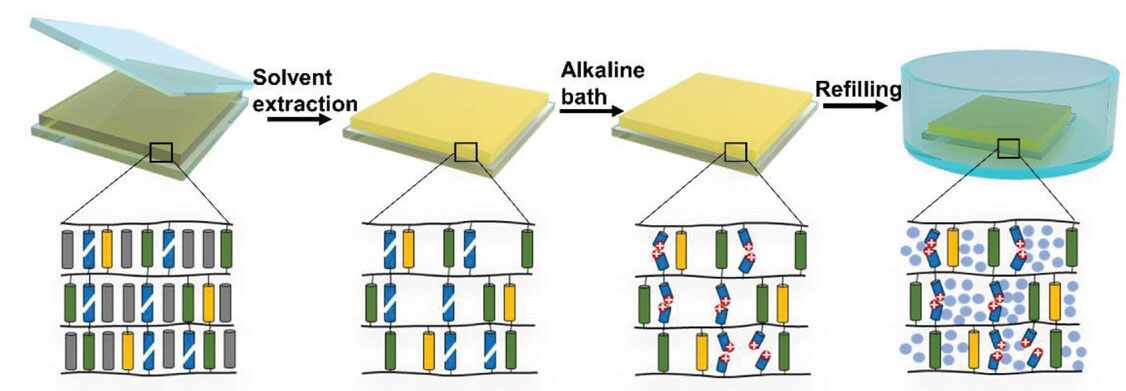

| The team’s smart skin layers utilize a liquid crystal polymer network (LCN) material blended with photoresponsive azobenzene molecules. The LCN contains specifically engineered nanoscale pores infused with ionic solutions. Ultraviolet light exposure triggers azobenzene cis-trans molecular configuration flipping, making the aligned LCN molecules lose order. This contraction squeezes pores, pumping out liquid. Solutions used include polyethylene glycol, ethylene glycol or ionic salts dissolved in water. | |

|

|

| Fabrication procedure of the LCN coating on a glass substrate. (Reprinted with permission by Wiley-VCH Verlag) | |

| The artificial skin uniquely enables proximate polymer reactions. As a demonstration, the researchers filled separate LCN layers with potassium thiocyanate (KSCN) and iron (III) chloride (FeCl3) solutions. Contact triggered an immediate color change reaction between the two chemicals. When Fe3+ ions interact with transferred SCN- ions, a vibrant red iron(III) thiocyanate coordination complex form. This visual indicator verifies both the LCN’s liquid transfer capacity and reactive potential. | |

| Skin layers can alternate between send and receive modes. After accepting solution, skins return liquid when illuminated, completing a two-way transfer. The technology facilitates multi-step cascading reactions across chains of three or more reactive skins. Variable light exposure timing provides precise control over chemical release rates from fractions of a second to minutes. Different skin pore dimensions can be manufactured, optimizing material compatibility with diverse organic and inorganic compounds. | |

| The materials demonstrate high efficiency and accuracy during iterative send/receive cycles. In trials, an initial skin A sent 60% of its solution to receiver B when triggered by UV light. Skin A then transmitted an additional 19% liquid to a second receiver B1. Future surfaces engineering improvements aim to further enhance transmission yields. | |

| Uniquely, the artificial skin layers also enable proximate reactive chemistry. The team filled separate skins with potassium thiocyanate solution and iron (III) chloride solution. Contact triggered an immediate color change reaction. Spatially patterned light exposure through photomasks imprinted corresponding shapes onto receiving surfaces during transfer. This level of signaling specificity holds promise for intricate communication protocols. | |

| The researchers highlight potential applications including human-robot interfaces, multi-agent coordination, drug production, chemical analysis, microfluidics, programmable surfaces and smart sensor networks. The technology provides a foundation for artificial intelligence systems to interpret and react to environmental chemical signatures. Adaptive response capabilities could enable robot teams to collaborate by exchanging situational updates, behavior cues and task assignments. | |

| The study demonstrates key innovations required to recreate intrinsic biological processes with synthetic materials. However, realization of full-scale practical implementations still requires further investigation. While promising, current technology limitations need addressing before widespread commercial deployment. | |

| Ongoing research aims to optimize fabrication techniques and pore configurations to maximize production yields above 60%. The team is exploring alternative photo responsive molecules to improve control precision and modulation rates. | |

| Studying longer term chemical stability, material degradation modes, toxicity thresholds, and biocompatibility factors will be essential for applications involving human interactions, medical devices, and food production. Analyzing security risks and environmental impacts is also critical. Investigating alternate coating substrates like elastomers would enable integrating technology onto wearable devices and robot exteriors. Larger testing environments are necessary to understand real-world operational dynamics across temperature, humidity and atmospheric chemistry fluctuations. | |

| Additionally, fully decentralized multi-agent coordination through chemical signaling remains theoretically viable but experimentally unvalidated. Creating complex emergent multi-robot behaviors comparable to natural systems like ant colonies through artificial pheromones remains aspirational. Studying collective group decision making dynamics must precede hypothesizing about potential societal impacts. | |

| Further interdisciplinary collaboration between material scientists, roboticists and computer scientists is critical to address these open challenges. Creative design approaches combining insights across bioinspired engineering, adaptive manufacturing and embodied AI offer paths to realize ambitious goals. Refining smart materials for advanced chemical communication constitutes an important milestone along the long horizon quest to replicate multifaceted biological cognition. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|