| Jan 30, 2024 | |

Sustainable battery electrode material derived from tea waste |

|

| (Nanowerk Spotlight) The transition to renewable wind and solar power faces a pivotal roadblock in the lack of affordable large-scale energy storage options. Without cost-effective grid-level batteries, fluctuation and intermittency issues make widespread adoption of sustainable generation impractical. After promising strides reducing production expenses for components like solar panels and wind turbines, storage technology has emerged as the last remaining hurdle to be cleared. | |

| Despite intense R&D from leading battery companies, prevalent lithium-ion chemistries struggle to achieve the combination of low prices, safety, stability, and high cycle life required for this application. The emerging potential of sodium-ion batteries has re-energized efforts, but their success hinges upon the development of suitable electrodes without excessive rare or toxic materials. | |

| In a paper published in Advanced Functional Materials ("Tea-Derived Sustainable Materials"), a team led by Dr. Xingcai Zhang at Harvard University details their development of a high-performance sodium-ion battery anode using an innovative material derived from waste tea leaves. Building off recent advances that have made sodium-ion batteries a viable and low-cost alternative to prevalent lithium-ion technology, the researchers’ biomass-sourced anode demonstrates qualities that could enable the next generation of affordable and sustainable grid-level energy storage. | |

| Previous attempts at sodium-ion batteries have achieved low cost but suffered too greatly in performance areas like charge capacity, longevity, and charging rates to displace lithium-ion dominance. Much of this stems from fundamental chemistry challenges, as the larger size of sodium ions restricts rapid movement within battery components. The central advance of Dr. Zhang’s tea leave anode lies in the way it balances these inherent limitations. | |

| Through a straightforward one-step pyrolysis process, the researchers convert raw tea leaf stems into a “hard carbon” material optimized for sodium-ion storage. Compared to existing carbon-based anodes, the team’s waste tea-derived hard carbon, dubbed TS-1400-HCl, delivers substantially improved metrics across the board. It provides 70% higher initial capacity, 91% higher efficiency in the very first charge/discharge cycle, and 7-9x greater longevity over 500 cycles. Critically, TS-1400-HCl achieves this breakthrough performance using only inexpensive base components via a scalable industrial process. | |

|

|

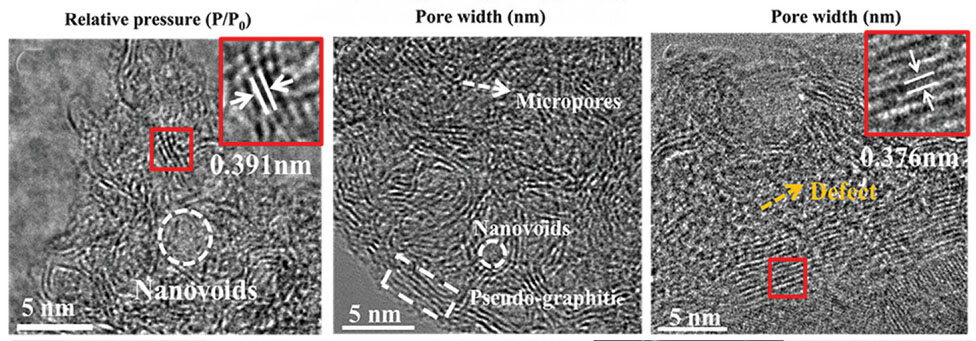

| HRTEM image of TS-1400-HCl. (Reprinted with permission by Wiley-VCH Verlag) | |

| The researchers attribute TS-1400-HCl’s capacities to structural enhancements enabled by the precursor tea leaf stems and strategic acid treatment. Its naturally porous biomass structure facilitates electrolyte penetration while retaining ample defects and voids for sodium ion adsorption. Acid washing removes impurities that led to capacity loss in raw form. This two-pronged approach results in an optimized carbon anode imparting expanded spacing between graphite-like layers, abundant adsorption sites across micro and mesopores, and excellent structural robustness over repeated charging. | |

| Through spectroscopic analysis, Dr. Zhang’s group confirmed TS-1400-HCl’s sodium ion storage occurs via a surface adsorption process filling pores and defects, followed by intercalation between graphitic sheets deeper in the bulk electrode. This dual mechanism, leveraging strengths of the tailored biomass hard carbon texture, makes full use of the material to ensure high capacity and electrical efficiency. | |

| Real-world feasibility tests of a full sodium-ion coin cell further cemented TS-1400-HCl’s candidacy as a mass production electrode. Without even presodiating the anode to prime it for stability, Dr. Zhang’s tea leaf full cell with a Na3V2(PO4)3 cathode still achieved exceptional longevity over 1000 cycles and energy density competitive with commercial lithium-ion batteries. Such demonstrations of readiness with no specialized preprocessing underscore TS-1400-HCl’s viability and cost-effectiveness. | |

| The researchers estimate the inexpensive acid treatment and annealing used to produce their hard carbon anodes would enable competitive pricing around $5-7 per kg at scale. Combined with the abundance of raw tea leaf resources – China’s annual output alone exceeds 1 billion kg – Dr. Zhang’s group believes their biomass approach has strong potential for real sustainability and positive environmental impact as a mainstream, affordable battery material. | |

| With continued research into complementary cathode materials focused on performance maximization instead of cost reduction, sodium-ion batteries integrating electrodes like TS-1400-HCl could soon unlock mass adoption of large-scale clean energy storage and distribution systems. By turning waste into watts, the advent of cheap, durable and Earth-friendly grid batteries gets one step closer. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|