| Mar 01, 2024 | |

Sustainable aerogels transform food and electronic waste into pure gold |

|

| (Nanowerk Spotlight) Electronic waste poses one of the fastest growing waste challenges worldwide, with over 50 million tons generated annually. Yet hidden in obsolete devices lies substantial amounts of precious gold used in electronics manufacturing. Recovering these scarce and valuable metals in a scalable, eco-friendly manner remains an enduring technical hurdle. | |

| Conventional extraction techniques fail to efficiently separate trace gold constituents within complex e-waste streams also containing far more abundant base metals like iron or aluminum. Transforming both electronic and food waste simultaneously into new sustainable value has so far exceeded the capabilities of recycling technologies. | |

| Now, researchers at ETH Zurich have developed a promising sustainable solution to extract gold from e-waste by using amyloid aerogels derived from food waste. The approach offers promise as a closed-loop system that could provide reliable domestic supplies of gold while diverting two major waste streams from landfills. | |

| Building on recent research that showed amyloid protein nanofibrils can remove heavy metals from water, the authors demonstrate these remarkable aerogel adsorbents exhibit high selectivity for gold and can extract it directly from complex electronic waste solutions. | |

| The study, published in Advanced Materials ("Gold Recovery from E-Waste by Food-Waste Amyloid Aerogels"), offers a circular solution that achieves multiple sustainability objectives by transforming two waste streams into high value. If scaled successfully, this breakthrough could greatly increase global gold supplies in an eco-friendly manner to meet rising demand. It also pioneers a new generation of protein-based functional materials. | |

|

|

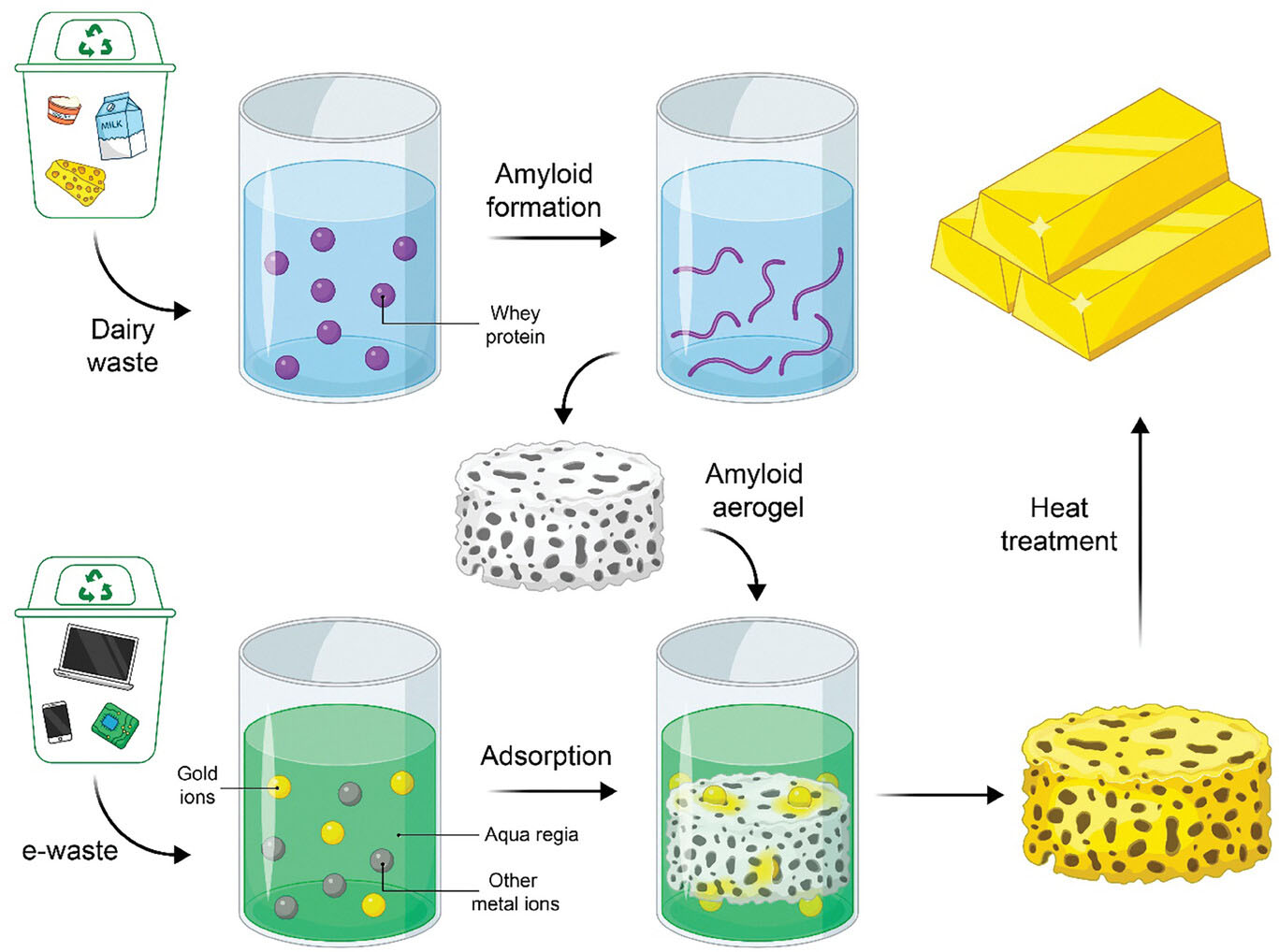

| Schematic route followed to generate neat value via pure gold, extracted from food waste (whey) and e-waste as starting source materials. (Reprinted with permission by Wiley-VCH Verlag) | |

Generating Neat Value from Waste Streams |

|

| The researchers’ key insight was realizing they could upcycle two very different waste materials – electronic waste and food byproducts such as whey – to create a valuable new commodity, purified gold. They aimed to develop an aerogel material from the protein in whey, a pervasive dairy industry waste stream, that could adsorb gold ions from acidic e-waste solutions. If successful, both the e-waste and whey waste streams would gain productive second lives, rather than causing environmental damage from landfilling or incineration. | |

| They first confirmed that amyloids, a unique class of highly ordered protein aggregate that confer structural stability, could be readily formed from the whey protein β-lactoglobulin under heating and acidification. These nanofibrils possess a tremendous surface area to volume ratio as well as abundant chemical groups that drive adsorption of heavy metals. They crosslinked the amyloid fibrils using environmentally benign small molecules to create rigid, porous aerogel monoliths with over 97% porosity that were both lightweight and mechanically robust. | |

Remarkable Gold Adsorption Capacity and Selectivity |

|

| The resulting amyloid aerogels displayed exceptional affinity toward gold compared to other common metals in e-waste such as iron, copper, zinc, lead, chromium and nickel. In several aqueous solutions containing equal concentrations of different metal ions, over 93% of gold ions consistently adsorbed to the aerogel, while adsorption percentages for other metals remained in the single digits. This impressive selectivity arises both from the intrinsic chelating interactions of gold to amino acids such as cysteine on the amyloid surface, as well as electrostatic attraction between the anionic gold ions to the positively charged aerogel under acidic conditions. | |

| Gold adsorption reached 94% completion in under 5 minutes due to highly efficient mass transfer to abundant binding sites, with maximum measured capacities over 1,800 milligrams of gold per gram of aerogel – an order of magnitude above conventional activated carbon used currently. The researchers found the amyloid aerogels performed well across a diverse range of gold concentrations and solution pH levels. Equilibrium adsorption isotherm analysis determined these bio-based gels can capture 55 millimoles of gold per liter of saturated fibrils. | |

| In addition to rapid sequestration of ionic gold, the amyloid aerogels facilitated clean reduction and crystallization into pure gold flakes and nanoparticles on their porous surface. Microscopy and spectroscopy fully verified a portion of extracted gold existed as pristine hexagonal crystalline platelets 55 nanometers thick. Intriguingly, the proteins appear to constrain growth on certain facets of the gold crystals, promoting flatter 2D morphologies rather than spherical particles. | |

Efficient Extraction of Pure Gold from E-Waste |

|

| Encouraged by these initial findings, the group proceeded to validate if the aerogels could selectively retrieve gold from genuine electronic waste rather than pure solutions. They dissolved computer motherboards, a standard e-waste component, in hydrochloric and nitric acid to free trapped metals into soluble ionic form. Despite gold concentration over five thousand times lower compared to other metals such as iron and copper in this complex mix, the amyloid aerogels extracted 66.8% of all dissolved gold after passive exposure, outpacing absorption percentages for all other elements. | |

| Heating the gold-loaded gels released pure metallic gold nuggets constituting over 90% by weight gold, with trace copper and nickel impurities. This 21-22 carat gold purity far exceeds industry standards for high karat jewelry, demonstrating exceptional selectivity for liberating gold even from solutions with far more abundant competing metals. Economic analysis found operational expenses average around $1.10 to obtain each gram of near pure gold using this bio-based aerogel technique, compared to a prevailing gold market price of $50 per gram. | |

| In addition, comprehensive environmental impact modeling revealed substantial reductions in carbon emissions, fossil energy consumption, water pollution and other damages compared to conventional recovery methods. The high yield from e-waste solutions, benign materials and superior sustainability metrics confirms amyloid aerogels’ promise as an economically competitive green production strategy to reclaim gold from discarded electronics. | |

| This pioneering research fertilizes innovation at the intersection of protein engineering, advanced materials and circular resource usage to sustainably transform food and electronic waste into high value gold. If successfully commercialized, such an approach could provide society reliable domestic supplies of gold in an eco-friendly manner, decreasing reliance on mining while diverting waste streams from landfills. | |

| More broadly, it highlights the potential of protein-based modular biomaterials to serve as adaptable next-generation platforms for selective capture and release of scarce elements from unconventional sources. There remain open questions surrounding scale-up synthesis and integration with existing e-waste recycling infrastructure that must be addressed before widespread adoption. | |

| Overall, though, the demonstrated technical viability and multiple sustainability dividends showcase the power of synergistic waste valorization to cost-effectively manufacture premium commodities and stimulate sustainable development. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|