| Apr 23, 2024 | |

Smart fabrics that cancel noise and sculpt sound |

|

| (Nanowerk Spotlight) Imagine a future where the fabric of your curtains, wallpaper, or even clothing could actively cancel out disruptive outside noises – creating quiet spaces in busy homes, offices, or during your daily commute. What if these fabrics could also be "tuned" to dynamically adjust the acoustics of a room, optimizing the sound quality for activities like music listening, conversation, or peaceful sleep? Such capabilities could transform everyday environments and our relationship with sound. | |

| While this vision may sound like science fiction, a recent breakthrough in the field of acoustic materials brings it one step closer to reality. | |

| Chronic exposure to noise pollution is a widespread public health issue, with over 145 million people in the US alone subjected to potentially harmful noise levels according to the World Health Organization. While technologies like noise-canceling headphones offer respite in limited situations, controlling sound over larger spaces remains a significant challenge. | |

| Traditional methods for reducing noise in buildings rely on sound-absorbing materials like thick fibrous panels, which are often bulky, unsightly, and less effective at lower frequencies. Alternatively, active noise control systems emit "anti-noise" sounds to cancel out unwanted noise but are difficult to implement at large scales. | |

| In search of new solutions, a study published in Advanced Materials ("Single Layer Silk and Cotton Woven Fabrics for Acoustic Emission and Active Sound Suppression") investigates an unexpected candidate for advanced sound control: ordinary woven fabrics. The researchers, based primarily at MIT, recognized the untapped potential for thin, lightweight textiles to function not only as transmitters of sound vibrations but as active acoustic systems capable of generating and manipulating sound waves. | |

|

|

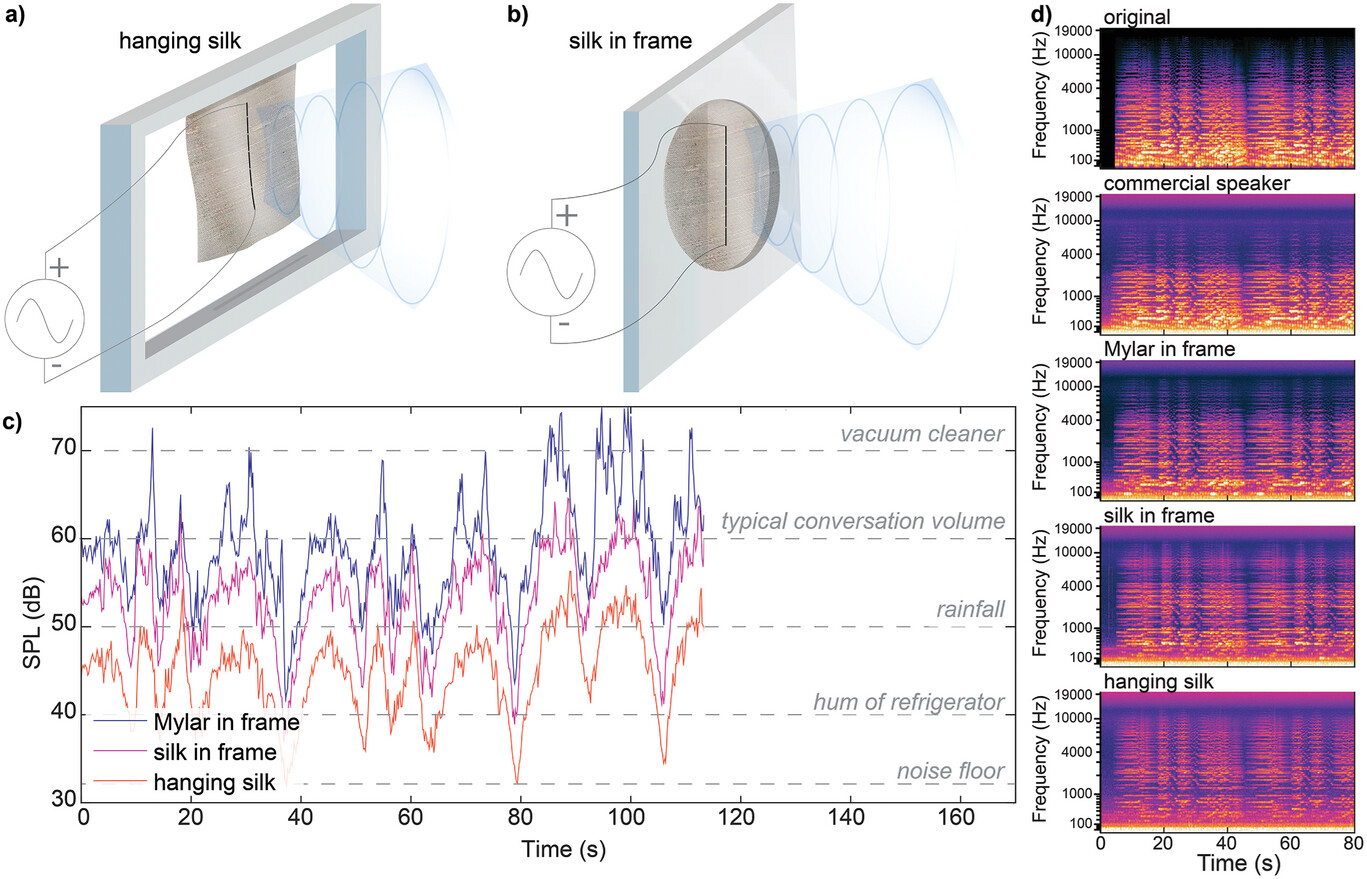

| Silk fabric samples a) in a hanging state and b) mounted in a circular frame. The AC symbol represents the voltage supplied to each fabric. c) SPL (measured at 2.5 cm) emitted by Mylar in a frame, silk in a frame, and the hanging silk over the course of playing “Air” (Bach). Examples of sounds at various SPLs are provided for reference. d) Spectrograms of the original audio and recordings from a commercial speaker, the Mylar in a frame, the silk in a frame, and the hanging silk. (Image: Reprinted from DOI:10.1002/adma.202313328, CC BY) | |

| To build their "fabric speaker," they began by creating a flexible piezoelectric fiber roughly 1 mm in diameter. At the fiber's core is a piezoelectric material, a type of "smart" material that expands and contracts when stimulated by an electric voltage. This is surrounded by electrode layers and a protective outer cladding. When alternating voltage is applied, the fiber rapidly bends back and forth, acting as a vibration generator. | |

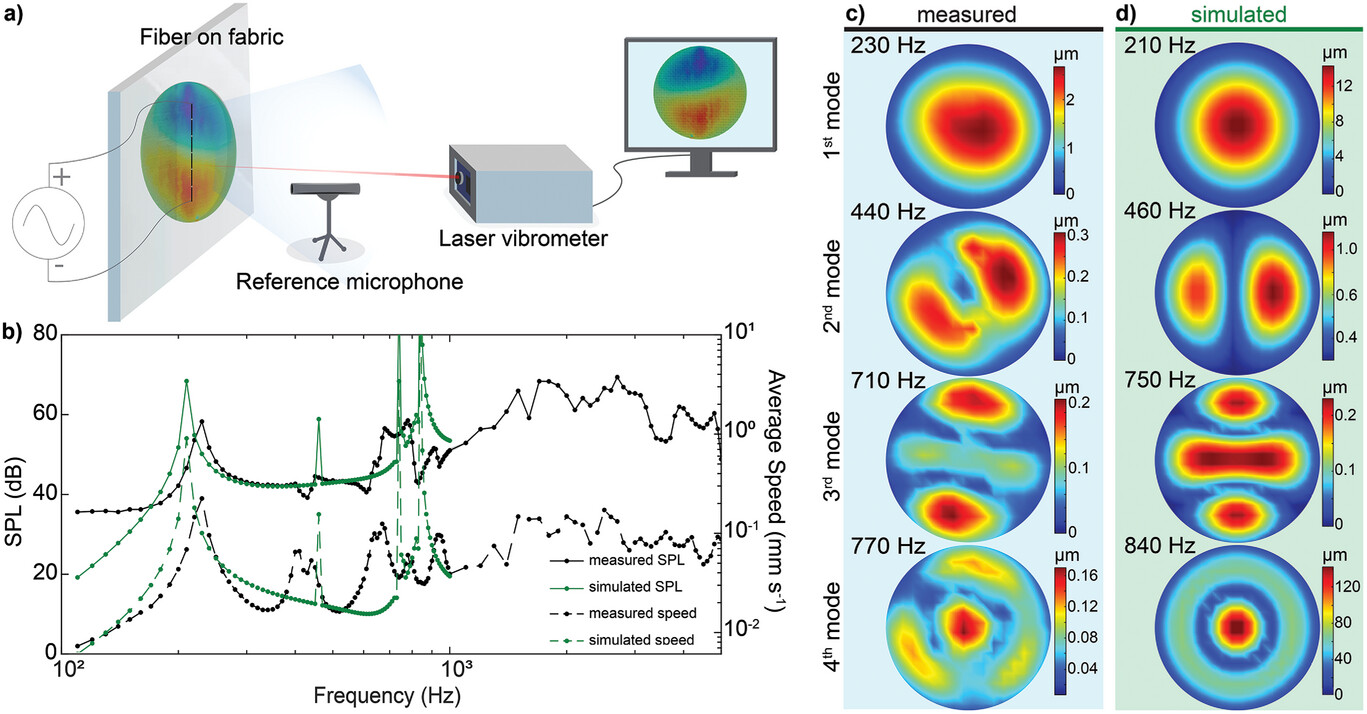

| Single strands of this piezoelectric fiber, ranging from 7 to 12 cm long, were then stitched onto various fabric samples including silk, cotton muslin, and canvas. Despite the complex woven structure, the fabrics closely mimicked the vibrational patterns of a simple rectangular or circular plate – a well-understood classical system in acoustics. With the actuating fiber attached, the textiles functioned as audible speakers, producing sound levels up to that of normal conversation. | |

|

|

| a) Schematic of the measurement setup for collecting SPL and velocity data from a fabric speaker in a frame. b) Measured frequency response of the average speed and SPL of the fiber-on-canvas loudspeaker and results from COMSOL simulations. The noise floor is around 35 dB. c) Measured displacement patterns compared to d) the simulated displacement patterns of the first four resonant modes. (Image: Reprinted from DOI:10.1002/adma.202313328, CC BY) | |

| Interestingly, the researchers found that the fabric's pore size influenced its acoustic efficiency. In the tightly woven silk, most pores were smaller than the thin layer of air that "sticks" to the yarns' surfaces due to viscosity. This allowed the silk to effectively push air to generate sound waves. The muslin, with looser pores, let more air pass through which reduced its sound emission. | |

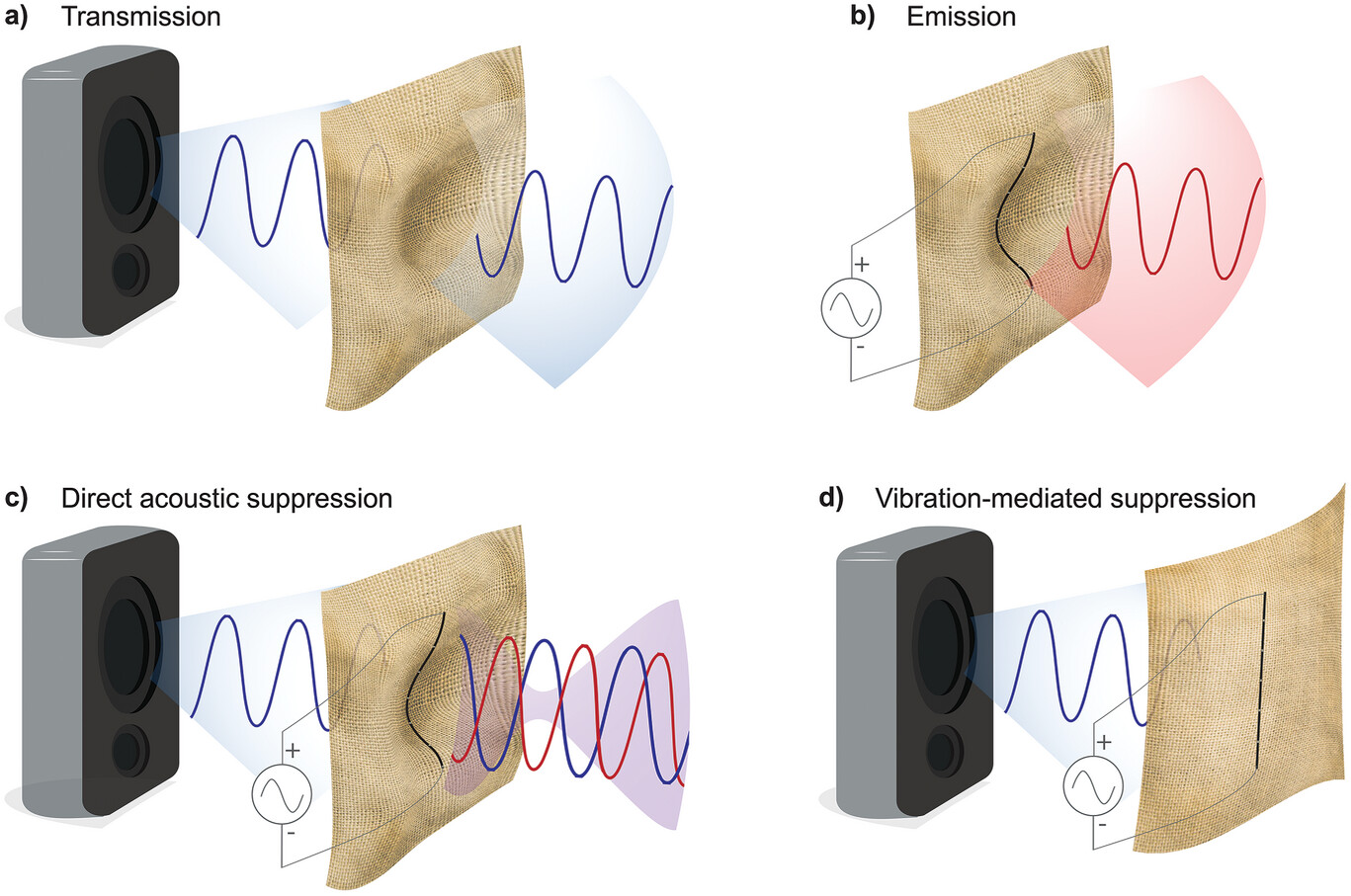

| However, the true value of these fabric speakers lies in their unique capabilities for active sound control. In one mode, the speaker generates sound waves perfectly opposite to incoming noise, so the two cancel each other out. The team demonstrated this could reduce sound by an impressive 37 decibels at a given location. | |

| Even more remarkable was a second sound-blocking mechanism, which relies on suppressing vibrations in the fabric itself. Many sounds we hear originate from or are transmitted through vibrating solid objects. By using the piezoelectric fiber to induce offsetting vibrations, the researchers "pacified" the fabric's motion, achieving a 95% reduction in its surface vibrations and a 75% drop in transmitted sound. | |

| Incredibly, this vibration cancellation blocks sound everywhere beyond the pacified fabric. An intriguing side effect is that sounds blocked from vibrating the fabric are instead reflected away, with the fabric's reflectivity increased by up to 68%. | |

|

|

| a) In transmission mode, incoming sound waves give rise to vibrations in a passive fabric. These vibrations transfer energy to the air in the form of sound. b) The piezoelectric fiber in the fabric causes the fabric to vibrate, leading to the emission of sound. c) Sound waves resulting from the sound which is transmitted through the fabric interfere with sound waves induced by the piezoelectric fiber vibrating the fabric. This interference can cause the cancellation of the sound at a particular point in space. d) The piezoelectric fiber induces mechanical vibrations that destructively interfere on the surface of the fabric with those induced by the incoming sound waves, subduing the fabric surface and precluding sound transmission through it. (Image: Reprinted from DOI:10.1002/adma.202313328, CC BY) | |

| The findings hint at a future where lightweight acoustic fabrics can be used to dynamically sculpt noise and soundscapes in buildings, vehicles, machinery housings or wearable devices. The thin fibers may be imperceptibly integrated during textile manufacturing to maintain the material's appearance and feel. | |

| Challenges remain in scaling these lab prototypes for complex real-world noise control, likely requiring networks of many piezoelectric fibers and advanced machine learning control algorithms to precisely counter noise sources. The long-term durability and energy efficiency of actively driven fabrics will also need to be established. But this research highlights an exciting new direction, transforming fabrics into intelligent acoustic interfaces through the power of smart materials science. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|