| Posted: Jul 21, 2006 | |

Discovery of new structural evolution of carbon nanotubes |

|

| (Nanowerk Spotlight) Researchers at the University of Sydney have revealed a new structural evolution of carbon nanotubes (CNTs) in epoxy composites during contact sliding and have shown that the evolution has three stages which are a) the bonding breakage of the CNTs, b) the formation of sinusoidal shells, and c) the consolidation of nanoparticles. This may present a potentially effective way to obtain nanoparticles with controlled structure and size. | |

| Deformation of carbon nanotubes CNTs, including those in composites, has attained extensive research attention. Professor Liangchi Zhang from the School of Aerospace, Mechanical and Mechatronic Engineering at the University of Sydney studied the deformation and structural transformation of CNTs in an epoxy composite when subjected to contact sliding stresses (wear tests). | |

| "The deformation mechanism revealed by our study was never discovered before, but it is critical to the tribological behavior of composites reinforced by CNTs" Zhang explained to Nanowerk. He published his recent findings, titled "Structural evolution of carbon nanotubes in composites under contact sliding stresses" in the June 12, 2006 online edition of Applied Physics Letters. | |

| "We discovered several very interesting deformation mechanisms of CNTs" says Zhang, "namely sinusoidal distortion of carbon outer shells and another type of deformation where the carbon shells deform to the whole depth of CNT walls and have nearly semicircular shapes." | |

| After the wear tests the researchers also detected CNTs with open and closed ends. Those with closed ends were not altered by contact sliding. However, CNTs with open ends were generated during wear. | |

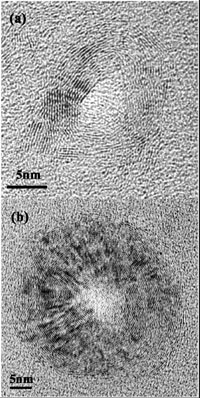

| "More interestingly" Zhang notes, "nanoparticles were found in the composite after the wear tests. These nanoparticles were similar to those obtained by electron irradiation or ball milling and were of two main kinds. Some of them have faceted or partly faceted walls. Another kind of nanoparticles has spherical shapes, resembling an onionlike structure. Since an irradiation source does not exist in our wear test the transformation from the faceted to the onionlike structure must have been due to the deformation caused by sliding stresses. The onionlike nanoparticles are also the most stable." | |

|

HRTEM images of nanoparticles on the sample’s surface after weartest; (a) a faceted nanoparticle and (b) an onionlike nanoparticle. (Reprinted with permission from American Institute of Physics) |

| The sliding stress must be high enough for this structural evolution to occur. Zhang and his team applied a pressure of 8.36 GPa in their wear tests, well above the 5.3 GPA that is required to break the ends of CNTs in sliding motion. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.