| Posted: Jul 28, 2006 | |

Single nanoribbon sensor as an in situ monitor |

|

| (Nanowerk Spotlight) Nanoribbons, which are attracting much attention due to their well-defined geometry and perfect crystallinity, require complex and expensive equipment to fabricate. Researchers in China have succeeded in fabricating a single nanoribbon sensor and demonstrated its use as a potential in situ monitor to track blood glucose levels, suitable for potential use by diabetics. | |

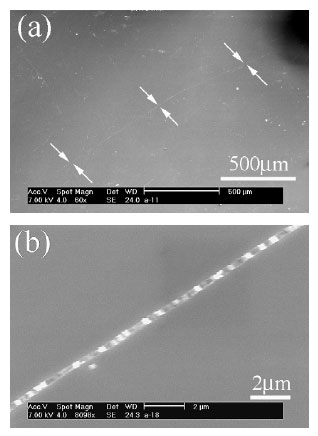

| Nanoribbon sensors are often made from ZnO or SnO2. The Chinese researchers synthesized long nanoribbons, millimeters in length, with a super high width-to-thickness ratio from the mineral mullite (2SiO2·3Al2O3) – a crystal that has needle like structures and, due to its properties, is a valuable ingredient to products that need to withstand high temperatures, corrosive environments, or other adverse conditions. Mullite is an important constituent in porcelain and other ceramics. | |

| Professor Mingwang Shao from the Anhui Key Laboratory of Functional Molecular Solids at Anhui Normal University in PR China, together with colleagues from the Center of Super-Diamond and Advanced Films at City University of Hong Kong, recently published a paper, titled "Single mullite nanoribbon as a glucose sensor" were published in the June 26, 2006 online issue of Nanotechnology. | |

|

Shao explains the benefits of their research to Nanowerk: "Our results show that our mullite nanoribbon sensor may be used to detect tear glucose and track blood glucose. In situ monitoring of glucose in the human body is usually based on the equilibrium that normally exists between blood and tissue fluid. Tear glucose is the one commonly used: it has a lower glucose concentration (50–500 µM) and relatively lower protein concentration with only slight changes in pH, and can directly relate to and track blood glucose levels which are 5–10-fold higher. Detection of tear glucose is safe compared with that of blood glucose. These intrinsic advantages make it possible for a mullite single nanoribbon sensor to be used to track tear glucose levels and therefore blood glucose levels, suitable for potential use by diabetics." To fabricate a sensor, a nanoribbon and a graphite chip served as electrodes in an electrical circuit. The millimetric length and high width-to-thickness ratio of the nanoribbons made it easy to fabricate a single nanoribbon device with the help of a microscope. When the two electrodes were immersed into solution, the current voltage curves were measured. This sensor shows long-term stability and good reproducibility after two months of storage. |

The SEM images of a single nanoribbon with: (a) length larger than 2 mm and (b) width about 340 nm. (Reprinted with permission from IOP Publishing) |

|

| "The high width-to-thickness ratio made it easy to fabricate a single nanoribbon sensor" Shao says, "and, because of its mineral nature, our sensor had higher stability than other nanoribbon sensors." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.