| Posted: Nov 03, 2008 | |

Nanotechnology that will rock you |

|

| (Nanowerk Spotlight) Forget boxy loudspeakers. Researchers have now found that just a piece of carbon nanotube (CNT) thin film could be a practical magnet-free loudspeaker simply by applying an audio frequency current through it. These nanotechnology loudspeakers – which are only tens of nanometers thick, transparent, flexible, and stretchable – can be tailored into many shapes and mounted on a variety of insulating surfaces, such as room walls, ceilings, pillars, windows, flags, and clothes without area limitations. The scientists demonstrated that their CNT loudspeakers can generate sound with wide frequency range, high sound pressure level, and low total harmonic distortion. | |

| The CNT thin film was put on a flag to make a flexible flag loudspeaker with dimensions of 8 cm by 14.5 cm. Don't forget to turn the sound on! | |

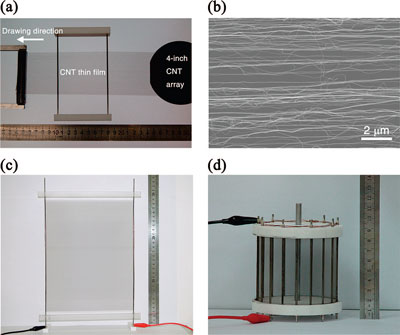

| Back in 2002, a group of Chinese researchers developed a technique for the creation of continuous carbon nanotube (CNT) yarns that were as long as 30 centimeters. They did this simply by drawing the yarns out from super-aligned arrays of carbon nanotubes ("Nanotechnology: Spinning continuous carbon nanotube yarns"). Super-aligned CNT arrays differ from ordinary vertically-aligned CNT arrays by their 'super-aligned' nature, i.e., the CNTs in super-aligned arrays have a much better alignment than those in ordinary arrays. The key feature of a super-aligned CNT array is that continuous thin films or ribbons, which are composed of a thin layer of parallel pure CNTs, can be directly drawn from it in solid state. These thin films are transparent and conductive, with aligned CNTs parallel to the drawing direction. | |

| Developing this work further, in 2005 the same group of scientists successfully synthesized super-aligned CNT arrays on 4-inch silicon wafers. One wafer of super-aligned CNTs is capable of being transformed into a continuous thin film which is up to 10 cm wide and 60 meters long ("Spinning and Processing Continuous Yarns from 4-Inch Wafer Scale Super-Aligned Carbon Nanotube Arrays"). | |

| "Near the end of 2007, we found that just a piece of carbon nanotube thin film could emit loud sound simply by applying an audio frequency current through it" Dr. KaiLi Jiang tells Nanowerk. "But the sound frequency doubles that of the input. We attributed this to the thermoacoustic effect. The alternating current periodically heated the CNT thin films, resulting in a temperature oscillation. The temperature oscillation of thin film excites the pressure oscillation in the surrounding air, resulting in the sound generation." | |

| Jiang, an Associate Professor in the Department of Physics & Tsinghua-Foxconn Nanotechnology Research Center at Tsinghua University in Beijing, explains that the thermoacoustic effect, which has been studied for more than 200 years, has led to the invention of thermoacoustic engines and even loudspeaker-driven refrigerators ("Thermoacoustic Engines and Refrigerators"). | |

| "But we have not heard of the thermoacoustic effect induced by alternating current" says Jiang. "We thought we were the first to discover such a thermoacoustic effect induced by alternating current, until in April 2008, one of us found papers published more than 100 years ago that had reported that ultra-thin metal wires or foils made of platinum and fed by alternating current could emit sound. The inventors called their device the 'thermophone' ("On Some Thermal Effects of Electric Currents" and "Notiz über Thermophonie"). It appears that these findings have been ignored for more than 80 years due to the very weak effect that initially was demonstrated." | |

| Jiang explains that the reason why platinum foils sounds weak but CNT thin film sounds loud has to do with the heat capacity per unit area (HCPUA) – a key parameter that determines the sound generation efficiency. | |

| According to the theory proposed by Arnold and Crandall ("The Thermophone as a Precision Source of Sound"), the sound efficiency is inversely proportional to the HCPUA value. For 700 nm thick platinum foil the HCPUA is 260 times that of the Chinese team's CNT film. The sound emitted by platinum foil therefore is roughly 260 times weaker than that by CNT thin film with the same power input, according to the aforementioned theory. | |

| To fabricate their loudspeakers, Jiang and his collaborators put the as-drawn CNT thin film directly on two electrodes, forming a simple loudspeaker. By putting several thin films together the loudspeaker area can be increased with no limitation on its size. The films can also be tailored into arbitrary shapes or put on arbitrarily curved surfaces to make loudspeakers with special functions. | |

|

|

| Carbon nanotube thin film loudspeakers. (a) The CNT thin film was pulled out from a super-aligned CNT array grown on a 4 inch silicon wafer and put on two electrodes of a frame to make a loudspeaker. (b) SEM image of the CNT thin film showing that the CNTs are aligned in the drawing direction. (c) A4 paper size CNT thin film loudspeaker. (d) The cylindrical cage shape CNT thin film loudspeaker can emit sounds to all directions, diameter 9 cm, height 8.5 cm. (Reprinted with permission from American Chemical Society). | |

| The CNT loudspeakers have excellent acoustic performance and, when hooked up to a simple amplifier, the CNT thin film loudspeaker exhibits all the functions of a voice-coil loudspeaker, as well as the merits of being magnet-free and without moving components. But in contrast to conventional loudspeakers, they possess several remarkable features – they are stretchable, transparent, and flexible – that will allow the fabrication of novel and unique loudspeaker applications. An example might be laptop computers where the current audio system could be replaced simply by putting a transparent loudspeaker film over the display area. Another example is their application in revolutionary new design concepts for tomorrow's electronics such as the Nokia Morph mobile phone. | |

| Another advantage compared to conventional loudspeakers is that the CNT loudspeakers don't vibrate and are damage tolerant. They will work even if part of the thin film is torn or damaged. | |

| Jiang notes that the team's next steps are to develop real products of CNT loudspeakers. "There is no doubt that more and more applications will be developed as time goes on. Our technique might open up new applications of and approaches to manufacturing loudspeakers and other acoustic devices." | |

| The team, which included scientists from the Department of Physics and the Tsinghua-Foxconn Nanotechnology Research Centre at Tsinghua UniVersity and the Department of Physics at Beijing Normal UniVersity, reported their recent findings in the October 29, 2008 online edition of Nano Letters ("Flexible, Stretchable, Transparent Carbon Nanotube Thin Film Loudspeakers"). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.