| Posted: Sep 26, 2006 | |

Carbon nanotube forests as non-stick workbenches |

|

| (Nanowerk Spotlight) The ubiquitous static friction (stiction) and adhesion forces comprise a major obstacle in the manipulation of matter at the nanoscale. In order to realize the potential of nanotubes and nanowires as components in electronic devices or other microsystems, methods for reliable pick-and-place assembly must be established. A major obstacle here is the delicate balance required between the adhesion forces acting between the object to be manipulated, and the surface and the manipulation tool, respectively. A group od Danish and UK researchers found that self-assembled organic nanofibers, which are otherwise totally impossible to remove from any normal surface, can be lifted straight off from a nanotube forest. It means that the notorious stickiness of even the most soft and fragile materials, which immobilizes them and prevent handling, is a problem that now can be solved. | |

| Kjetil Gjerde, a Ph.D. student at the Department of Micro- and Nanotechnology at the Technical University of Denmark, explains the new findings to Nanowerk: "A forest of carbon nanotubes has an incredible low adhesion to most materials. The key is the extremely small effective surface area. Any object suspended on a nanotube forest will in a sense hardly touch it." | |

| Gjerde is first author of a recent paper, titled "Carbon nanotube forests: a non-stick workbench for nanomanipulation", that was published in the September 11, 2006 online edition of Nanotechnology. Also involved in this work were researchers from the Nanointegration project at Technical University of Denmark, the nanotube research at Cambridge University in the UK, and the nano research at the University of Southern Denmark. | |

| In general, adhesive and frictional forces depend on the effective surface area in contact between two objects. Uniquely, when using the nanotube forest, only the nanotube tips are in contact with the object, minimizing the effective contact area greatly and hence lowering the total stiction and adhesion forces. The ability of each individual carbon nanotube (CNT) to bend in any direction as a response to an applied force makes the nanotube forest mechanically compliant, expanding the possibilities for three-dimensional manipulation compared to existing techniques. | |

| "Nobody thought of CNTs as a coating of surfaces or microsystems as a non-stick coating" says Gjerde. "To use such a nanostructured workbench for solving the fundamental stiction challenge of nanomanipulation is entirely new. Moreover, the sharp tip we use to lift off the organic nanofibers, can go down between the nanotubes, under the nanofiber, and really lift it off. The nanotubes are flexible, and this makes the surface strangely compliant." | |

|

|

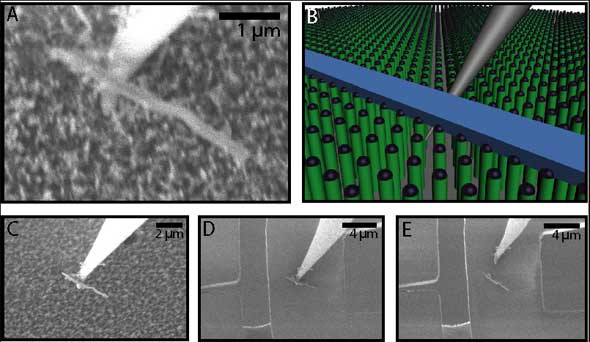

| (A) A tungsten tip approaches a nanofiber resting on top of a nanotube forest, and moved underneath the fibre. (B) Illustration of the technique used for manipulation of fragile organic nanofibers. An electrochemically etched tungsten tip is moved beneath the nanofiber slightly into the mechanically compliant nanotube forest. The nanofiber may then be lifted by pulling the tip vertically up. (C) The nanofiber is lifted off the nanotube forest by pulling the tip up. (D) The nanofiber is then placed onto electrode supports on another microchip. (E) By pulling the tip away, the nanofiber remains on the electrode support, as it has been moved from a surface with low adhesion to a surface with higher adhesion. (Reprinted with permission from Institute of Physics Publishing) | |

| Manipulation of fragile nanostructures, such as organic nanofibers, is nearly impossible on other low stiction surfaces. The low stiction combined with the compliance of the nanotube forest allow even structures that assemble by nothing but weak interactions, such as van der Waals forces, to be released without damage. | |

| "We are working in two EU projects (Nanorac and Nanohand) to realize reproducible, automated nanomanipulation" Gjerde points out. "Adhesion to surfaces is a huge problem, and we believe this work to be a crucial step towards three-dimensional nanomanufacturing. In any case, the range of objects we are able to interface to microcircuits has suddenly increased dramatically." | |

| The easy nanomanipulation provided by the CNT forest will facilitate manipulation of various structures but could also lead to CNT dressed manipulation tools. | |

| "We are now working towards functionalizing the manipulation tools themselves with carbon nanotubes, to facilitate not only easy pick, but also easy place operation of the nanostructures" Gjerde explains the next research steps. "We call these tools "hairy-MEMS" devices; there are quite a lot of potentially powerful concepts we are going to try out with them." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.