| Posted: Jul 03, 2015 |

Advancing the characterization of cellulose materials with state-of-the-art equipment

|

|

(Nanowerk News) The Paper and Fibre Research Institute (PFI), a leading cellulose research facility in Trondheim, Norway, has invested in new ion-milling equipment and scanning electron microscope for characterization of cellulose-based materials.

|

|

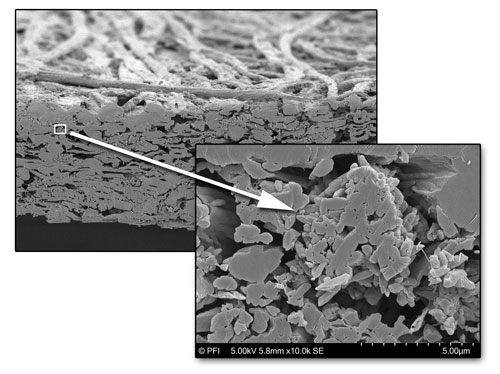

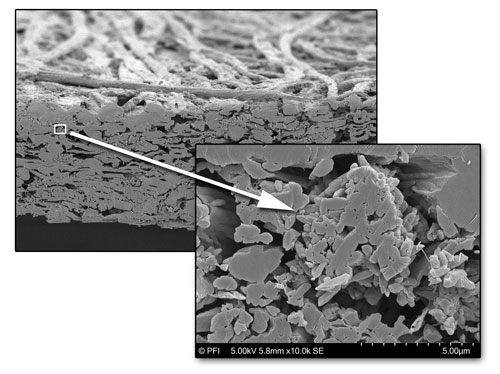

| Cross-section of an ion-milled paper sample. Note the mineral filler structure (right image) that is visualized with the new SEM. The new equipment for ion-milling and SEM are available at PFI. (Image: Per Olav Johnsen, PFI) (click on image to enlarge)

|

|

Cellulose is the most abundant biopolymer on Earth, and it is renewable and biodegradable. Cellulose fibres are extensively used by the pulp and paper industry as the major component in e.g. paper and tissue products. Nanocellulose – a nanomaterial derived from cellulose fibres – has many additional applications such as strength enhancer in paper and biocomposites, as barrier for packaging, as emulsifier, in enhanced oil recovery and in biomaterials for biomedical applications.

|

|

The potential applications of cellulose fibres and nanocellulose are many. However, a proper characterization is necessary to understand their properties and potential in various products.

|

|

The PFI has been one of the most contributing groups within structural characterization of cellulose-based materials. This is based on an extensive track-record with development of characterization procedures, including the development of preparation methods, microscopy and image analysis techniques.

|

|

As these examples show, PFI researchers have extensively contributed to the characterization of

|

|

fibres ("Assessment of transverse dimensions of wood tracheids using SEM and image analysis")

coatings ("Structure characterization of pigment coating layer on paper by scanning electron microscopy and image analysis "), and more recently

nanocellulose ("Quantitative Electron Microscopy of Cellulose Nanofibril Structures from Eucalyptus and Pinus radiata Kraft Pulp Fibers") and

biocomposites ("A non-destructive X-ray microtomography approach for measuring fibre length in short-fibre composites").

|

|

In order to advance the microscopy capabilities of cellulose-based materials and thanks to a grant from the Norwegian Pulp and Paper Research Institute foundation, PFI has invested in a modern ion milling equipment and a new Scanning Electron Microscope (SEM).

|

|

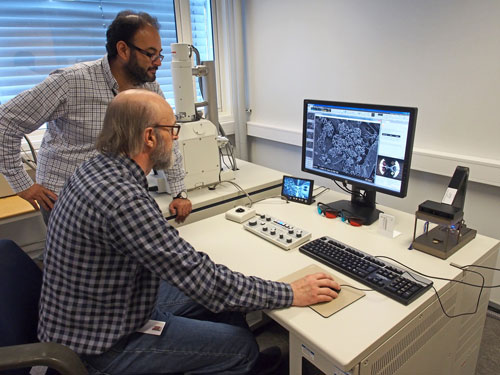

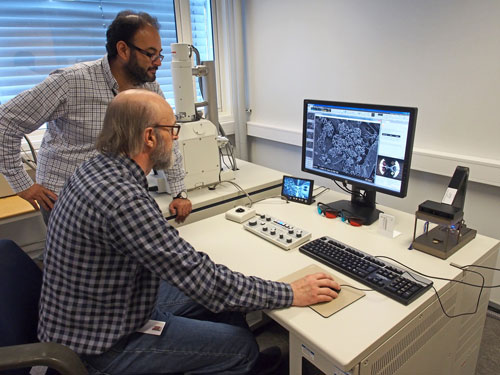

“There are several microscopy techniques that can be used for characterizing cellulose materials, but the scanning electron microscope is one of the most preferable ones as the microscope is easy to use, versatile and provides a multi-scale assessment”, explains Gary Chinga-Carrasco, lead scientist at the PFI Biocomposite area.

|

|

“However, good microscopy depends to a large extent on an adequate and optimized preparation of the samples”, adds Per Olav Johnsen, senior engineer and microscopy expert at PFI.

|

|

“We are always trying to be in front in the development of new characterization methods, facilitating research and giving support to our industrial partners”, says Chinga-Carrasco, who has been active in developing new methods for characterization of paper, biocomposites and nanocellulose and cannot hide his enthusiasm when he talks about PFI's new equipment. “In the first period after the installation it is important to work with the equipment with several material samples and techniques to really become confident with its use and reveal its potential”.

|

|

| PFI has invested in new equipment for preparation and imaging of cellulose-based materials. Lead scientist Gary Chinga-Carrasco and microscopy expert Per Olav Johnsen demonstrate the new SEM. (Photo: PFI)

|

|

He is backed up by microscopy expert Per Olav Johnsen. Johnsen has extensive experience with microscopy, being reflected in at least three decades of dedicated microscopy work. “For various applications, conventional cross-sectional analyses are suitable, for example fibre and paper samples. However, some applications are more demanding, for example nanocellulose and bionanocomposites. In such cases, the ion-milling equipment is most appropriate for preparing samples for further microscopy analyses. This will certainly complement our extensive toolbox for structural characterization”, adds Johnsen.

|

|

The team at PFI is now offering new methods for assessing cellulose materials in great detail. They point out that they have various activities and projects where they already see a big potential with the new equipment.

|

|

Examples for these efforts are the assessment of porous nanocellulose structures for biomedical applications (for instance in the NanoHeal program) and the assessment of surface modified wood fibres for use in biocomposites (for instance in the FiberComp project).

|

|

"We also expect that the new equipment and methods will open for new initiatives and cooperation with R&D groups and industry, including Norwegian projects or for example as part of Horizon2020 proposals," Chinga-Carrasco concludes. "We are excited with these opportunities, and some promising initiatives are already in progress."

|