| Posted: Apr 20, 2017 |

Clean water from a plant-based membrane

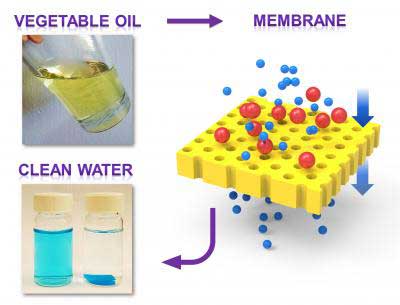

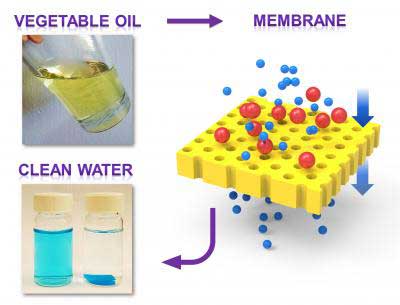

(Nanowerk News) A team of researchers has developed a plant-derived material that can be used to purify water potentially far more effectively than current petroleum-based membrane materials.

|

|

The researchers, in the lab of Prof. Chinedum Osuji, in collaboration with Prof. Menachem Elimelech, published their findings in in ACS Nano ("Highly Selective Vertically Aligned Nanopores in Sustainably Derived Polymer Membranes by Molecular Templating"). The material, a highly ordered and aligned nanoporous polymer, is based on natural fatty acids that are derived from vegetable oils.

|

|

|

“The structure you get is highly selective because the size of the pores is very well-defined, while the fact that the pores are aligned ensures extremely efficient operation,” said Osuji, Associate Professor of Chemical & Environmental Engineering. This selectivity means that the material could have a ready application in nanofiltration to rid water of contaminants, such as textile dyes, pharmaceuticals, pesticides, and other contaminants of emerging concern.

|

|

Xunda Feng, a co-author of the paper, noted that membrane-based technologies play an important role in water purification but that current technologies have two significant drawbacks.

|

|

“They have low selectivity,” said Feng, a postdoctoral associate in Osuji’s lab. “They are also fabricated entirely from petroleum-based materials.”

|

|

Due to environmental concerns, producing useful polymers from renewable or sustainably-derived materials has long been a goal of scientists seeking an alternative to petroleum-based materials. However, these alternatives have proved to have inferior performance.

|

|

To create the new material, the researchers used a technique known as molecular templating in which a single molecule acts as a guide for molecules of fatty acids to self-assemble into hexagonally packed columns. Because the fatty acid molecules don’t physically bond to the guiding molecule, the template can be removed, yielding nanopores. The size of the nanopores is precisely defined by the self-assembly process while the chemical nature of the nanopore walls is defined intrinsically by the fatty acid, or by simple chemical modifications performed after forming the membrane.

|

|

The membranes were tested in adsorption experiments to see how readily molecules of different sizes and different charge (positive or negatively charged) could enter the pores. The results were stunning – a small difference of just 0.4 nm (about 250,000 times smaller than the width of a human hair) resulted in a change from complete admittance to near-complete rejection of molecules, and the membranes displayed complete rejection of negatively charged molecules independent of their size. “These novel membranes can selectively transport water and desired molecules, but reject unwanted ones, in a manner that is superior to current commercially available membranes,” said Gilad Kaufman, a contributor to the project and a Ph.D. candidate in Osuji’s lab.

|

|

Kohsuke Kawabata, a co-author and postdoctoral associate in Osuji’s lab, noted that the synthesis of the template molecule is low-cost and scalable. Also, the template molecule that is eventually removed from the polymer membrane can be reused to produce additional membranes.

|

|

Osuji said his lab will continue working with Elimelech, the Roberto C. Goizueta Professor of Chemical & Environmental Engineering, to build on their discoveries.

|

|

“Now we want to make large films and examine their selectivity in pressure-driven flow, to see what molecules go through and which one don’t - basically scaling it up to practical membranes,” he said. The team will also explore other potential uses, such as for high-density nanopattern transfer for the semiconductor industry.

|