| Posted: Jul 12, 2017 | |

Researchers report a class of prototype nanocatalysts with streamline shapes(Nanowerk News) The roles of particle geometry on fluid-related gas-solid and solid-solution systems are fundamentally important. New work, reported in ACS Central Science ("Smart Nanocatalysts with Streamline Shapes"), represents the first example of synthetic preparation of streamlined nanocomposites (e.g., with a tadpole morphology) with complex chemical compositions in a tailorable fashion. |

|

| When an object moves through a viscid fluid, it experiences a drag force, which usually consists of pressure drag and frictional drag (scaling with the Reynolds number). | |

| It is broadly accepted that the shape of a particle has a great effect on the amount of drag produced. A streamline body represents a superior geometry since it faces minimum fluid resistance; well-known examples of this type are submarines in seawater or airplanes in air. | |

| Systems of heterogeneous catalysis can be viewed as dispersed solid-liquid (or solid-gas) flows. It has been well established that an optimal shape configuration of catalysts can promote the transport processes and thus enhance catalytic activity in the fixed bed reactors. | |

| However, to date, no studies have been attempted to adopt streamline catalysts in liquid phase heterogeneous catalytic reactions. This is perhaps due to the lack of easy-to-use techniques to produce catalyst particles with a streamline morphology. | |

|

|

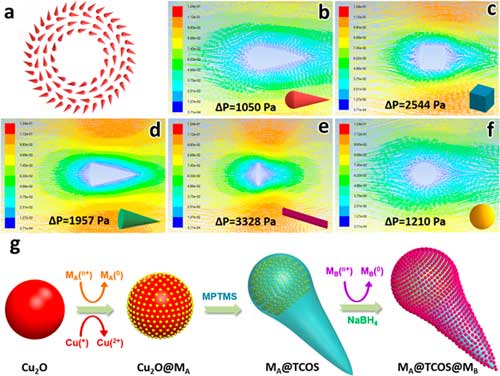

| Geometric consideration and synthesis of streamline catalysts. (a) The alignment of streamline catalyst particles in the presence of solvent flow. (b-f) Velocity vector plots of catalyst objects with various body shapes (flow rate 0.1 m·s-1 (water) and temperature 25°C). Geometrical shapes investigated include streamline body, cube, circular cone, flat plate, and sphere, which share the same projected frontal area. Color-code is used to indicate the strength of the flow velocity. (g) Schematic illustration of stepwise preparations of TCOS support and the derived catalysts. (© American Chemical Society) (click on image to enlarge) | |

| As the paper's authors from National University of Singapore show, streamline-shaped nanocatalysts indeed can reduce fluid resistance and have elucidated their structural benefits in catalytic applications compared to other commonly used counterparts. | |

| Generally, a lower drag endows catalyst particles with a greater fracture resistance during the reaction, whereas the tubular, cylindrical extrudates have the disadvantage of low crushing strength and abrasion resistance. | |

| In a simple estimation, the researchers calculate that streamline catalysts can give 16% more surface area than a spherical catalyst of equivalent volume. Therefore, it is highly desirable to add streamline features to catalysts and elucidate the impact of particle shape on their catalytic performance. | |

| "Therefore, we envision that future development of streamline-based hybrid materials (e.g., tadpole-shaped copper organosilicate that was constructed by the team), in combination with various functional nanostructured materials, will play a greater role in the design and synthesis of new generation catalysts or sorbents for multiphase processes," the authors conclude. "Apart from the heterogeneous catalysis studied in the current work, sorptive separation and chemical sensing could also be future research topics using this class of materials. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |