| Jun 13, 2011 |

Graphene: Foaming for stretchable electronics

|

|

(Nanowerk News) Graphene's remarkable conductivity, strength and elasticity has made it a promising choice for stretchable electronics — a technology that aims to produce circuits on flexible plastic substrates for applications like bendable solar cells or robotic-like artificial skin. However, integrating the polymers needed for such applications with typical chemically derived graphene results in composites with poor conductivity due to severe structural defects in the graphene layers and large inter-sheet contact resistance.

|

|

Hui-Ming Cheng and co-workers from the Chinese Academy of Sciences' Institute of Metal Research at Shenyang have now devised a chemical vapor deposition (CVD) method for turning graphene sheets into porous three-dimensional 'foams' with extremely high conductivity ("Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition"). By permeating this foam with a siloxane-based polymer, the researchers have produced a composite that can be twisted, stretched and bent without harming its electrical or mechanical properties.

|

|

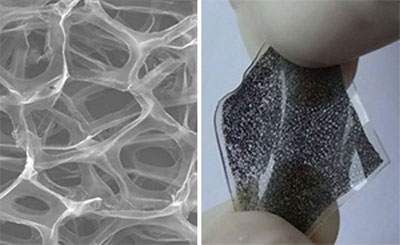

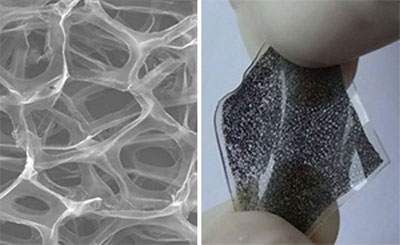

| A scanning electron microscopy image of the net-like structure of graphene foam (left), and a photograph of a highly conductive elastic conductor produced from the foam. (© 2011 NPG)

|

|

Scientists originally produced graphene by peeling apart graphite crystals. The use of CVD to grow defect-free graphene directly onto metal substrates, however, is emerging as a better approach for large-scale production. During their CVD experiments, Cheng and his team noted a curious aspect about their graphene structures—they exactly mimicked the underlying metal framework no matter whether it was flat or curved.

|

|

Inspired by this finding, the researchers attempted to generate a three-dimensional graphene structure using porous nickel foam—a substance often found in nickel–hydrogen batteries—as a CVD template. After exposing the nickel foam to methane gas at 1,000 °C and etching away the nickel template, the team produced a lightweight, free-standing foam containing near-perfect graphene sheets linked into a robust three-dimensional network structure (see image).

|

|

The graphene foam's exceptional 99.7% porosity enabled the team to readily incorporate polydimethylsiloxane elastomers to produce a graphene–polymer composite with conductivity a million times higher than achieved in previous attempts. Because the foam's conductivity remains nearly unchanged even under large applied strains, Cheng foresees a wide range of possible applications for this approach.

|

|

"Graphene foams have a unique network structure, large surface area, very low density and outstanding electrical and mechanical properties," says Cheng, "In addition to stretchable electronics, this novel material may find use in energy storage, fuel cell electrodes, thermal management, electromagnetic shielding and biomedical supports."

|