| Jul 05, 2013 |

An all-glass lab-on-a-chip

|

|

(Nanowerk News) Lab-on-a-chip devices are microfluidic cells that incorporate pipes, reaction vessels, valves and a host of other implements typically found in laboratories. These components are typically carved into a flat plastic plate smaller than a credit card to enable efficient processing of microliter-volume samples. The use of plastic, however, has several drawbacks that could be remedied by using glass. Unfortunately, glass chips have proved difficult to fabricate due to their fragility. Yo Tanaka from the RIKEN Quantitative Biology Center has now developed a reliable and durable system for incorporating glass microfluidics into lab-on-a-chip devices ("Electric actuating valves incorporated into an all glass-based microchip exploiting the flexibility of ultra thin glass ").

|

|

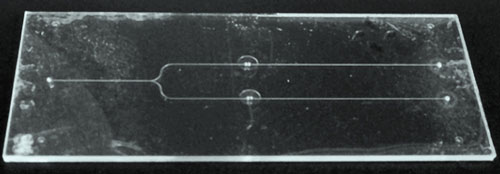

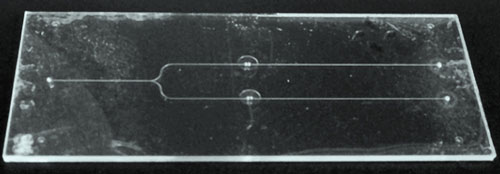

| An all-glass lab-on-a-chip.

|

|

Most lab-on-a-chip devices are formed from polydimethylsiloxane (PDMS), an inexpensive plastic that is easy to pattern with microfluidic elements. Valves, in particular, take advantage of the plastic’s elasticity—simply applying or releasing pressure can close or open a channel in the device, controlling fluid flow.

|

|

Plastics, however, have several disadvantages, including degradation when exposed to reactive chemicals and a tendency to adsorb sample molecules before they can be analyzed. They can also interfere with analysis techniques that rely on shining a light through the device due to their imperfect transparency. Glass is an attractive alternative because it is chemically resistant, transparent to light and also capable of withstanding higher fluid pressures than PDMS. Producing flexible and durable glass valves, however, has proved difficult.

|

|

To allow glass to be used in these devices, Tanaka developed a Teflon frame to hold an ultrathin sheet of glass so that it could be handled without breaking and incorporated the frame into an all-glass lab-on-a-chip (Fig. 1).

|

|

Next, Tanaka used hydrogen fluoride to etch channels and chambers into a pair of glass slides, and covered these chambers with ultrathin glass sheets in a way that allowed fluid to be prevented from passing through the chamber by simply pressing down on the glass cover. He then fused the glass sheets together by heating them at 750 °C.

|

|

After trying various thicknesses of ultrathin glass sheets, Tanaka found that a 10 micrometer-thick glass film was ideal: strong enough to withstand more than 100 depressions yet able to deform by up to 126 micrometers—enough to completely close the valve. Tests using water containing small fluorescent polystyrene beads demonstrated that closing the valve using this method blocked fluid flow within 0.12 seconds.

|

|

Tanaka now plans to develop his all-glass device for applications such as highly sensitive biochemical analyses and cell studies

|