| Oct 30, 2013 |

Researchers fabricate stable three-dimensional plasmonic nanoclusters

|

|

(Nanowerk News) Recent advances in nanotechnology have created a novel breed of optically active materials fabricated from highly-structured two-dimensional arrays of noble metal nanoparticles. Now, a team from Rice University in Houston, Texas, has developed a method to manufacture stable, three-dimensional (3-D) nanoclusters that could be used to impart metamaterial optical properties into unstructured substrates such as liquids, glasses and plastics ("Three-Dimensional Plasmonic Nanoclusters").

|

|

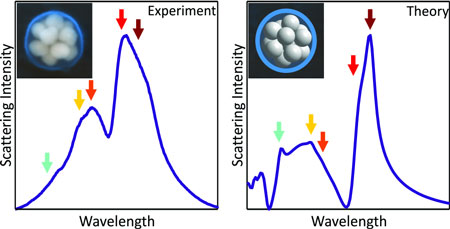

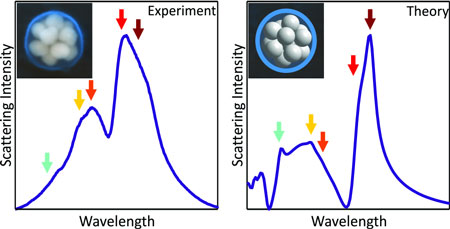

| Optical properties of icosahedral clusters: The experimental scattering spectra, with SEM image of 13-nanoparticle icosahedron inset, show strong agreement with FEM calculations, with 3-D model inset. Five localized surface plasmon (LSP) modes can be identified from the calculations (arrows), which can be found at the same position in the experimental spectrum.

|

|

The team, led by Professors Halas and Nordlander, chose an Andor iKon-M NIR-enhanced CCD camera coupled to a hyperspectral imaging system to collect the dark-field scattering spectra of individual nanoclusters. Their results reveal a very strong agreement between the experimental spectral characterisation of 3-D nanoclusters with varying configurations (number, geometry, and orientation of the cluster) and the team's theoretical calculations based on finite element analysis.

|

|

According to Professor Peter Nordlander, "The precise way in which the nanoparticles are arranged, rather than their composition, dictates the optical characteristics through an effect called localised surface plasmon resonance. Theory suggests that the optical properties of different nanoclusters should be either remarkably sensitive to, or highly independent of, nanoparticle number and cluster geometry and our results bear this out. The Andor iKon-M camera played a key role; the very low dark current due to the advanced thermoelectric cooling combined with high sensitivity over a large wavelength regime allowing us to image even very weakly-scattering nanoparticles to determine their optical properties. Demonstrating an efficient assembly method for plasmonic 'artificial molecules' or 'meta-atoms' is a significant step towards a new generation of optical emitters and sensors, molecular contrast agents, nanoscale lasers and superlenses."

|

|

Professor Naomi Halas adds, "The universality of the fabrication method could extend the use of plasmonic nanoclusters to other regions of the spectrum, either by incorporating different materials, for example, aluminium for the UV, or spherical core/shell nanoparticles, for example, nanoshells for the IR. They are also compatible with easily applied material coating methods, such as aerosols, and could lead to materials with transparency windows at specific frequencies and with constant ratios and linewidths. And, they could also enable electromagnetic characteristics not yet achievable in current types of metamaterials as well as new approaches to current technological challenges, such as high-throughput chemical and biological sensing."

|

|

According to Antoine Varagnat of Andor, "Metamaterial engineering provides exciting prospects for future photononics applications, such as, the fabrication of a 'super-lens' that can potentially overcome the diffraction limit associated with traditional lenses. The structural stability of the nano-bricks at the basis of these metamaterials is critical to ensure consistent and reliable, specific optical properties. For example, knowing that the optical response of an ideal tetrahedron should be virtually independent of cluster orientation is of little use if the 3-D plasmonic nanocluster is unstable. By encapsulating the 3-D nanoclusters in a small polymer sphere, the team at Rice University stabilised their geometry and made them resistant to a wide range of solvents and solutions. Their approach to robust, defined cluster self-assembly paves the way for the development of novel isotropic metamaterials, such as metafluids."

|