Nanocellulose explained

Content

What is Nanocellulose?

Nanocellulose is a derivative of cellulose, the most abundant organic polymer on Earth, largely present in the cell walls of plants.

Cellulose is a natural polymer discovered in 1838 by French chemist Anselme Payen. It was widely used before its discovery, in forms like wood and cotton, for energy, building, and clothing. In the last 150 years, we've chemically modified cellulose to create materials like celluloid, the first thermoplastic polymer, and synthetic fibers for textiles.

Cellulose is now recognized as the most abundant organic polymer on Earth and is primarily used for paper and cardboard. It's also used in industries like construction, pharmaceuticals, food, and cosmetics, and for creating environmentally friendly products. The unique structure and properties of cellulose make it suitable for specific applications, such as immobilizing proteins and separating molecules. It differs from synthetic polymers due to its distinct functionality, high chain stiffness, and sensitivity to hydrolysis and oxidation.

When cellulose is broken down to the nanoscale, it creates nanocellulose, a material that possesses remarkable properties such as high strength, light weight, and flexibility. There are several types of nanocellulose, including cellulose nanocrystals (CNC), cellulose nanofibrils (CNF), and bacterial nanocellulose (BNC), each with unique properties that make them suitable for specific applications.

Nanocellulose is notable for its impressive mechanical strength, comparable to Kevlar, and yet it is biodegradable, renewable, and exhibits a low thermal expansion coefficient. Owing to these properties, nanocellulose has found application in a host of areas including composites, packaging, paper and textiles, biomedicine, and notably, in electronics.

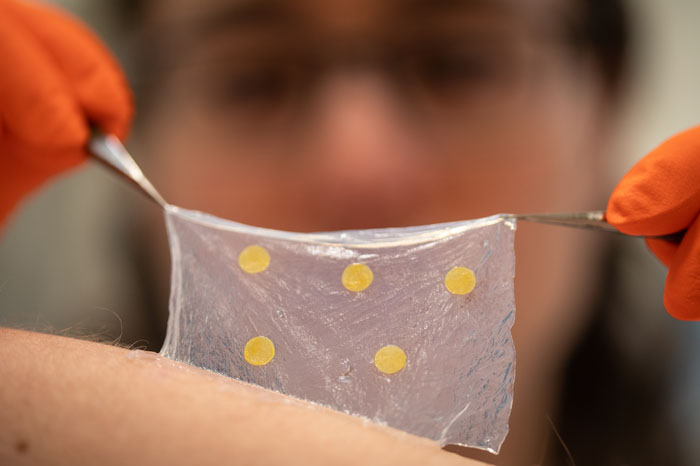

The biocompatibility of nanocellulose signifies its safety when in contact with living tissue. This unique characteristic earmarks nanocellulose as a promising material for various biomedical applications, such as tissue engineering and drug delivery. For instance, researchers have demonstrated nanocellulose wound dressing that can reveal infection.

A nanocellulose wound dressing that can reveal early signs of infection through a shift in color. (Image: Olov Planthaber)

One primary area of focus is the material's barrier properties. To maximize the potential application of nanocellulose, especially in high-humidity environments, scientists are working on ways to enhance its resistance to oxygen, water vapor, and other external factors. Efforts are currently underway to devise strategies for improving these properties to enable the widespread use of nanocellulose in diverse environments.

The future of nanocellulose in electronics

The electronics industry appears to be a promising field for the application of nanocellulose. Thanks to their high strength and lightweight characteristics, nanocellulose fibers are suitable for crafting flexible electronic elements like electrodes and transistors. When incorporated into electronic gadgets, these elements can pave the way for the creation of flexible screens, wearable electronic devices, and even implantable medical equipment, which could potentially transform our interaction with technology.

Researchers, in initial experiments, have already showcased a nanocellulose paper-based semiconductor and a conductive nanopaper produced from nanocellulose and silver nanowires. Given its optical properties, nanocellulose can also be used in the production of transparent electronics, an emerging field that could revolutionize products like displays, smart windows, and solar cells.

Portable solar cells based on foldable, lightweight, transparent, conductive cellulose nanofibre paper. (Image: CC-BY Macmillan Publishers Ltd)

Electronic paper is a technology that emulates the appearance of regular ink on paper. Compared to the traditional paper-based electronics, nanocellulose-based electronics promise increased flexibility, lightweight designs, and enhanced environmental resistance.

In assessing the state of the art, a recent review took a comprehensive approach, examining the entirety of the rapidly developing field of nanocellulose electronics. It scrutinized everything from optoelectronics and wearable electronics to solid-state electronics, covering a broad spectrum of relevant devices. While there have been significant advancements in recent years, the review also acknowledged the challenges currently faced in this area of research.

Quantum confinement effects and ligand effects brought about by nanocellulose also offer intriguing avenues for research. These phenomena, which arise due to the nanoscale dimensions of the cellulose particles, have been identified as factors that significantly enhance the electronic performance of devices integrating nanocellulose.

Other application areas for nanocellulose

Nanocellulose showcases tremendous potential in energy storage, offering an innovative alternative to traditional storage devices. It forms the basis for lighter, slimmer, and more flexible batteries and supercapacitors, poised to revolutionize energy storage. This breakthrough can impact various sectors, from consumer electronics to electric vehicles, and enhance the effective use of renewable energy.

In biomedicine, nanocellulose's superior biocompatibility is driving innovation. It's being used to fabricate films and membranes for repairing tissues and organs. Its potential role in drug delivery systems and tissue engineering further extends its reach in healthcare, fostering advancements in treatment and healing processes.

Nanocellulose also finds practical uses in industries like food packaging, water purification, construction, transportation, and aerospace. For instance, its optimal water retention and barrier properties are being utilized for developing efficient and eco-friendly food packaging. Research has yielded a method of using cellulose nanocrystals for advanced barrier coatings in food packaging.

Despite the myriad possibilities that nanocellulose offers, the path to its widespread application isn't devoid of challenges. A primary concern pertains to its barrier properties. For the material to be effectively used in high-humidity environments, it needs to demonstrate improved resistance to oxygen, water vapor, and other external elements. Consequently, current research is focusing on enhancing these barrier properties, enabling broader use of nanocellulose across different environments.

Conclusion

In conclusion, this review stressed the potential of nanocellulose as a catalyst for research and development in materials science and other related fields. With its remarkable properties and the possibilities it opens up for improving the performance of microelectronic devices, nanocellulose is set to be a game-changer. However, for it to achieve its full potential, researchers must continue to tackle the challenges and unlock the opportunities that this innovative material presents.

Looking forward, the exploration and development of nanocellulose-based electronics represent an exciting frontier in the integration of materials science with engineering and technology science. As this field continues to evolve, the impact of nanocellulose will undoubtedly become more and more profound, reshaping our understanding of what is possible in the realm of electronics.

Frequently Asked Questions (FAQs) on Nanocellulose

What is Nanocellulose?

Nanocellulose is a term used to refer to nano-structured cellulose. This material is derived from wood fibers and is completely renewable. There are several types of nanocellulose including cellulose nanocrystals, cellulose nanofibrils, and bacterial nanocellulose, all possessing unique properties making them ideal for various applications.

What are the properties of Nanocellulose?

Nanocellulose exhibits impressive characteristics including high strength, lightweight, and biodegradability. Additionally, it has high optical transparency, impressive thermal expansion properties, and can form gels, films, and dispersions. These properties make nanocellulose a suitable choice for various industries.

What are the applications of Nanocellulose?

Nanocellulose has a wide array of applications ranging from the food industry to electronics. In the food industry, it is used as a fat replacement, in electronics it is used in the production of displays, and in the medical field, it can be used for drug delivery systems. It's also being used in paper production, paints, and coatings.

Is Nanocellulose environmentally friendly?

Yes, nanocellulose is an environmentally friendly product. It is derived from renewable sources, primarily wood, and is fully biodegradable. Furthermore, the process of producing nanocellulose is comparatively less harmful to the environment than the production of many synthetic materials.

How is Nanocellulose produced?

Nanocellulose is produced by breaking down wood fibers into nanoscale particles. This can be achieved through several methods including mechanical, chemical, and enzymatic processes. The exact method depends on the desired properties of the final product.